Delta 20-330 User Manual

Page 13

13 - English

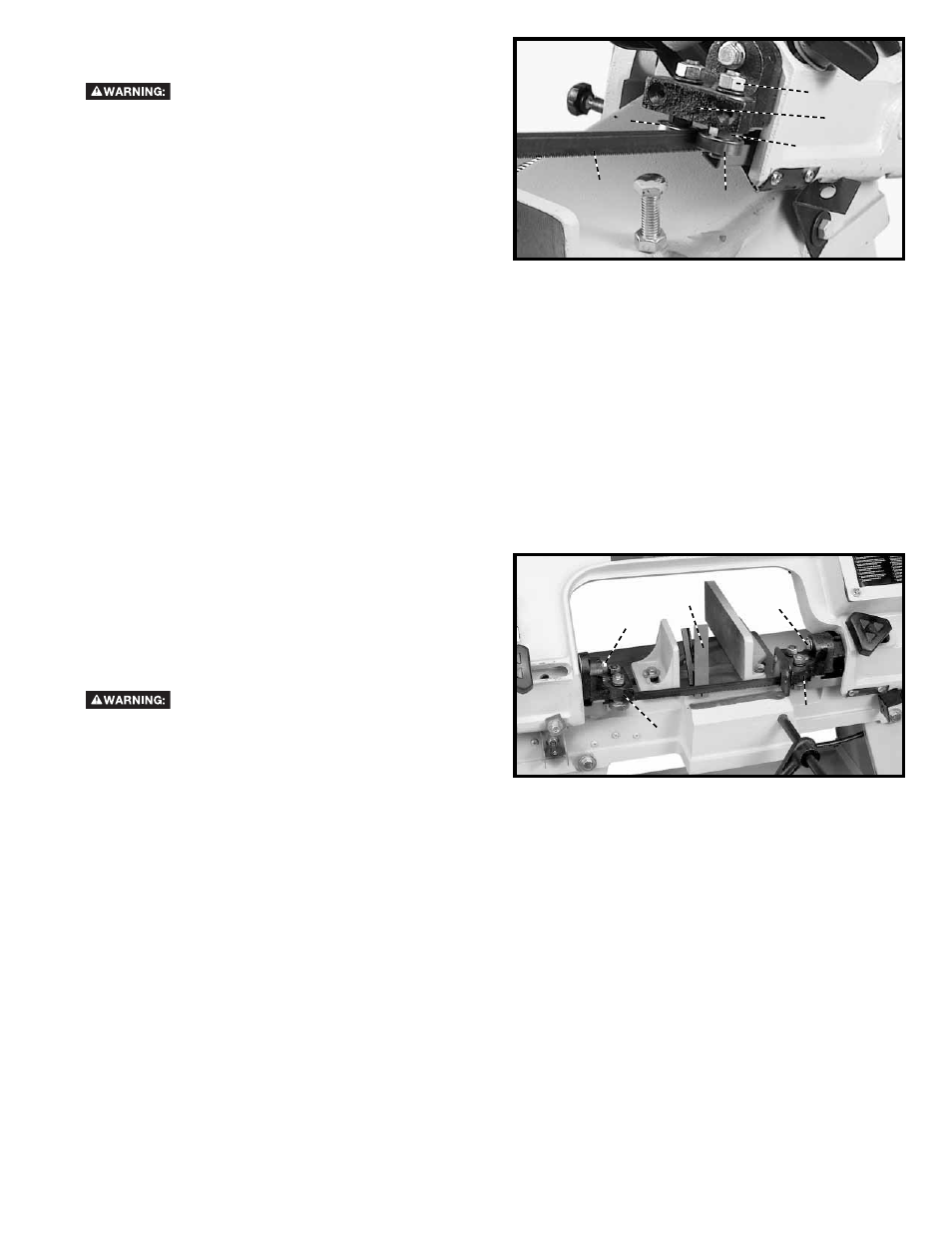

ADJUSTING BLADE GUIDE BEARINGS

Disconnect machine from power source.

1. The blade guide bearings (A) and (B) Fig. 20 should

be adjusted so they just touch the sides of the

blade (C) after the blade is tracking properly and the

blade support bearing has been adjusted. To adjust,

proceed as follows:

2. Remove the cover plate that is attached to the face

of the right guide bracket (D) Fig. 20.

3. The inside guide bearing (A) Fig. 20, is mounted to

a fixed shaft and cannot be adjusted. The outside

guide bearing (B) is mounted on an eccentric shaft

and should be adjusted so that the sides of the

blade (C) just contact the guide bearings (A) and

(B). To adjust, loosen nut (E) and turn adjusting nut

(F) until proper adjustment is made. Then tighten

nut (E).

4. Adjust the other blade guide bearings in the same

manner.

Fig. 20

ADJUSTING BLADE 90 DEGREES TO THE

TABLE SURFACE

In order for accurate work to be accomplished on

your saw the blade must be at 90 degrees to the table

surface. To check and adjust, proceed as follows:

Disconnect machine from power source.

1. Lower the saw arm to the horizontal position. Place

a square (A) Fig. 21, on the table with one end of

the square against the blade, as shown.

2. If the blade is not at 90 degrees to the table, loosen

the two screws (B) Fig. 21, that attach the blade

guide brackets to the guide arms and rotate both

guide brackets (C) until the blade is at 90 degrees

to the table. Then tighten the two screws (B). NOTE:

CARE SHOULD BE TAKEN NOT TO DISTURB

THE BLADE GUIDE SUPPORT BEARINGS WHEN

MAKING THIS ADJUSTMENT.

Fig. 21

A

B

B

B

F

A

D

E

C

C

C