Delta 20-330 User Manual

Page 12

12 - English

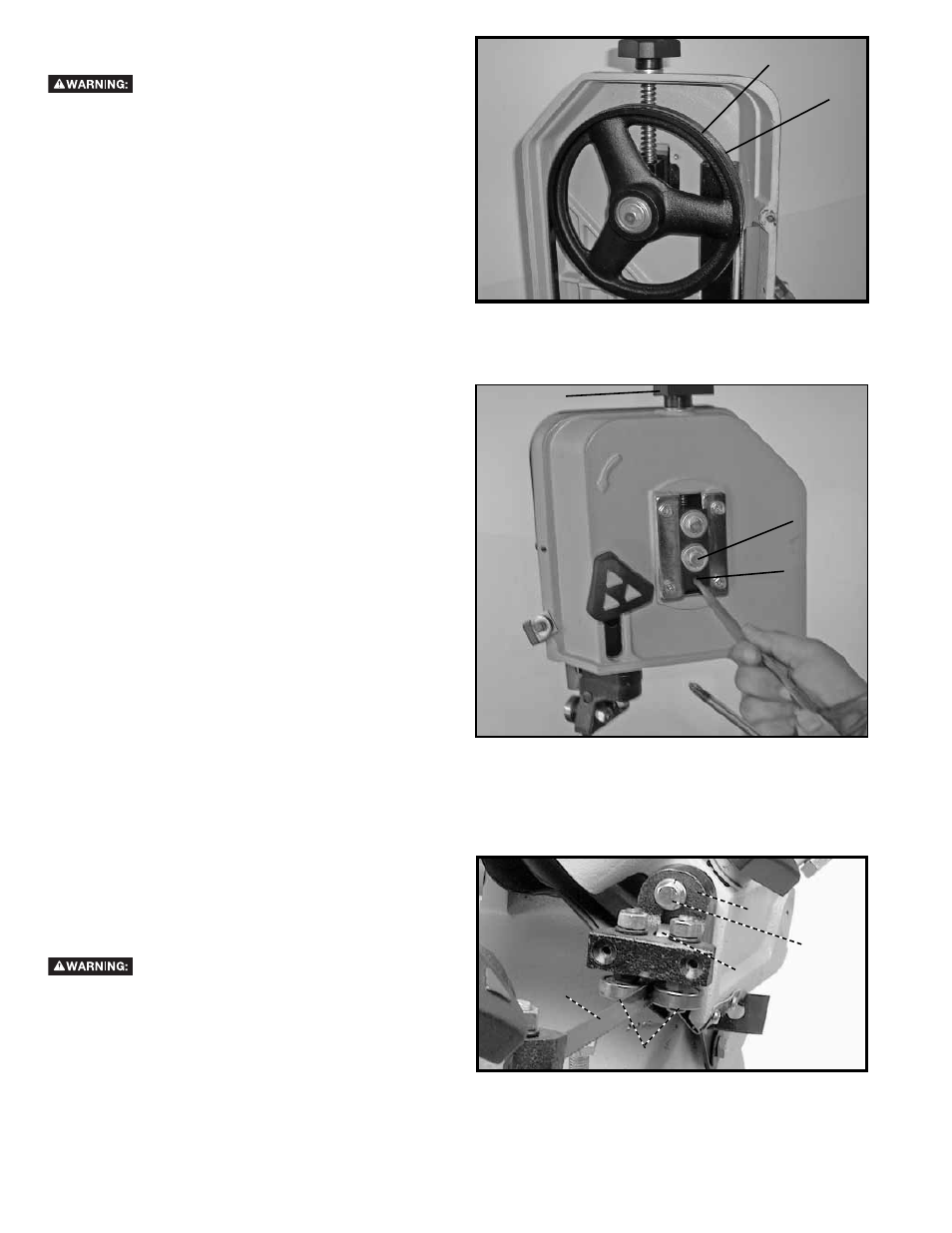

ADJUSTING BLADE TRACKING

Disconnect machine from power source.

1. Place the saw arm in the vertical position and open

the wheel cover.

2. Turn on the band saw. The blade is tracking

properly when the back of the blade (B) Fig. 17, is

just touching the edge of the wheel flange (C). The

back of the blade should not be rubbing against the

flange.

3. If an adjustment is necessary the blade guide

bearings and blade support bearings (J) Fig. 19 (two

of which are shown) should be clear of the blade.

4. Loosen screw (D) Fig. 18.

5. With the band saw running, turn adjusting screw (E)

until the blade is tracking properly making certain

blade tension is maintained by turning blade tension

knob. (F). The blade is tracking properly when the

back side of the saw blade just touches the flange

on the wheel.

6. Tighten screw (D) Fig. 18, when adjustment is

complete.

7. IMPORTANT: IT IS POSSIBLE WHEN MAKING

THIS ADJUSTMENT TO OVER TIGHTEN THE

ADJUSTING SCREW (E), FIG. 18, AND CAUSE

THE BLADE TO BE MISALIGNED. If this happens,

loosen the adjusting screw (E) several turns but do

not remove it from its threaded hole and loosen

screw (D). Turn screw (D) clock-wise until it stops

but do not tighten. Then turn the adjusting screw (E)

clockwise until it bottoms. Turn on the machine and

turn adjusting screw (E) clockwise a small amount

at a time until the blade is tracking correctly and

tighten screw (D) Fig. 18.

8. After the blade is tracking properly make sure to

ad-just the blade guide bearings and blade support

bearings.

Fig. 17

Fig. 18

ADJUSTING BLADE SUPPORT BEARINGS

Disconnect machine from power source.

1. The blade support bearing (F) Fig. 19, should be

adjusted so it just touches the back of the saw

blade after the blade is tracking properly. To adjust,

loosen screw (G) and move the bracket (H) up or

down until the support bearing (F) just touches the

back of the blade (I). Then tighten screw (G).

2. Adjust the other blade support bearing in the same

manner.

Fig. 19

D

E

F

H

G

F

I

J

B

C