Delta 20-330 User Manual

Page 10

10 - English

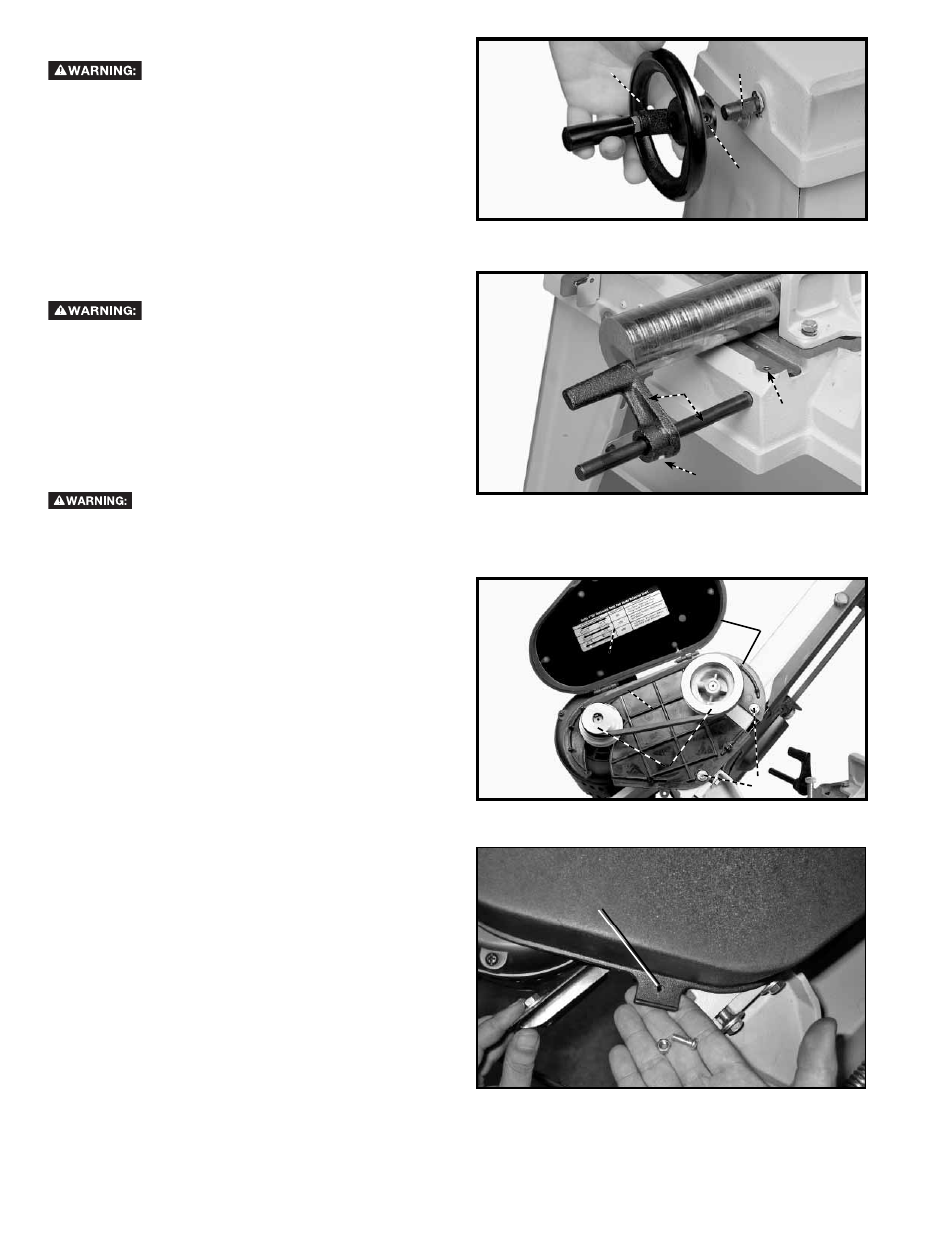

ASSEMBLING VISE HANDWHEEL

Disconnect machine from power source.

Assemble the vise clamping handwheel (T) Fig. 4, to the

shaft (U), and tighten set screw (V) against the flat on

the shaft (U).

Fig. 11

T

U

V

ASSEMBLING STOCK ADVANCE STOP

Disconnect machine from power source.

Assemble the stock advance stop assembly (W) to the

hole on the front of the table and tighten the two set

screws (X), as shown in Fig. 6.

Fig. 12

ASSEMBLING GUARD AND BELT

Disconnect machine from power source.

Open the belt and pulley guard (A) Fig. 12A, and

position the bottom half of the guard assembly behind

the pulleys (B) as shown. Line up the two holes in the

bottom of the guard with the two threaded holes in the

casting. NOTE: DO NOT COMPLETELY TIGHTEN THE

PULLEY GUARD TO THE CASTING AT THIS TIME.

Place a 1/4" flat washer onto a 1/4-20x1/2" hex head

screw and insert screw through hole in pulley guard and

thread screw into the tapped hole in the casting. Repeat

this process for the remaining hole. Raise the motor and

assemble the belt (D), to the desired steps of the two

pulleys then release the motor. A speed selection chart

(E) is located on the inside of the guard cover. When the

belt is tensioned, tighten screws (C).

Fig. 12A

E

A

B

D

W

X

X

Fig. 12B

G

To lock guard closed during use, use the 3/16" hex

nut and 3/16"-1/2" round head screw. Insert the screw

through the two holes at (G) Fig. 12B and secure using

the hex nut.

C