Vortech 2009-2010 5.7L Hemi Cars (Charger, Challenger, 300C) User Manual

Page 31

P/N: 4CL020-015 v1.0, 12/02/2014

©2014 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

17

11. FUEL PUMP BOOSTER INSTALLATION

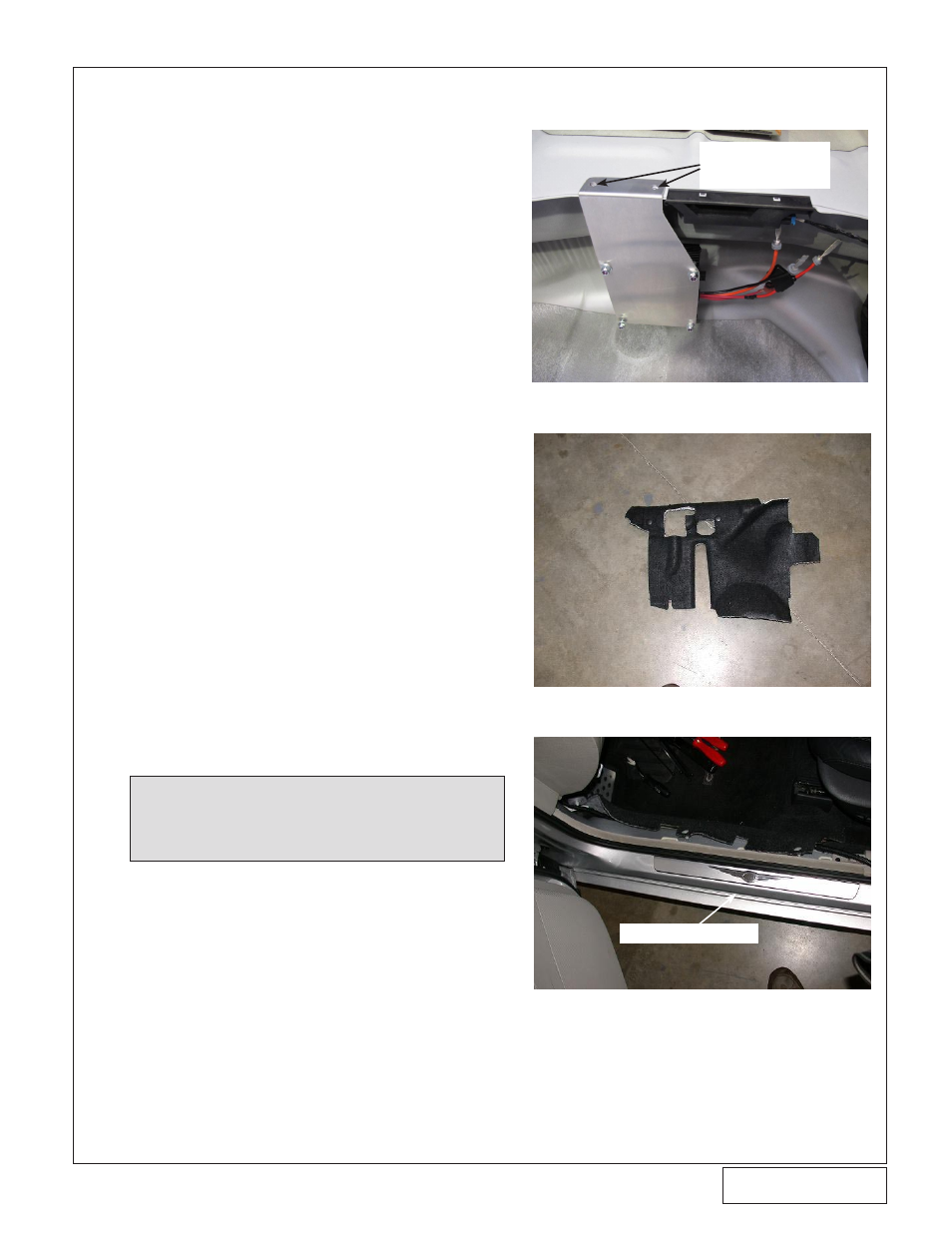

A. Open trunk and remove carpet to expose the

Styrofoam organizer in the spare tire well and

remove the organizer. Using the FPB mounting

plate as a template, mark (2) drill hole locations.

Using a 17/64” drill bit, drill through, at the two

marked locations (see Fig. 11-a).

B. Secure the supplied FPB to the mounting plate

with the provided # 10 hardware screws, wash-

ers, and nylock nuts. Then mount the FPB as-

sembly to the two previously drilled 17/64” holes

in the spare tire well using the provided ¼-20

screws, washers, and nylock nuts.

C. Locate the rubber grommet on the driver’s side

of the firewall. Make a small slice in the grom-

met.

D. Remove the two plastic clips securing the under

dash cover. Set aside the cover to be installed

in a later step. (See Fig. 11-b)

E. Lift up the driver side plastic door sill running

across the door and remove. (See Fig. 11-c) It

will be reinstalled in a later step.

F. Remove the rear seat by lifting up on each side

of the lower section. (The upper section does

not need to be removed)

G. Locate the supplied 1/8” nylon Instrument tubing

and install it into the 1/4” plastic split loom.

H. Route the 1/8” nylon tube assembly along the

door sill to the FPB previously installed in the

trunk. Secure the loom with provided tie wraps.

Locate the 7/64 vacuum hose and cut a 2” piece

and install one end on the 1/8” nylon tube and

the other end to the vacuum port on the FPB.

Secure hose connections with tie wraps. This

will be used for boost reference.

I. Route the other end of the 1/8” nylon tube

assembly loom through the firewall grommet

(Previously cut in step 11-C) and into the engine

bay. Continue routing the tube assembly to the

5/32” tee fitting installed in the bypass valve

line. (Previous step 10-D) Cut another 2” piece

of 7/64” vacuum hose and attach to tee fitting.

Secure with plastic tie wraps.

Fig. 11-a

Fig. 11-b

Fig. 11-c

DOOR SILL

NOTE: When routing tubing, ensure nylon tubing

does not get kinked or potentially pinched

during vehicle operation.

DRILL TWO 17/64”

HOLES