Glazing guide, Ab b – Palram PALGAR User Manual

Page 31

PALSUN® PALGARD™

Glazing Guide

31

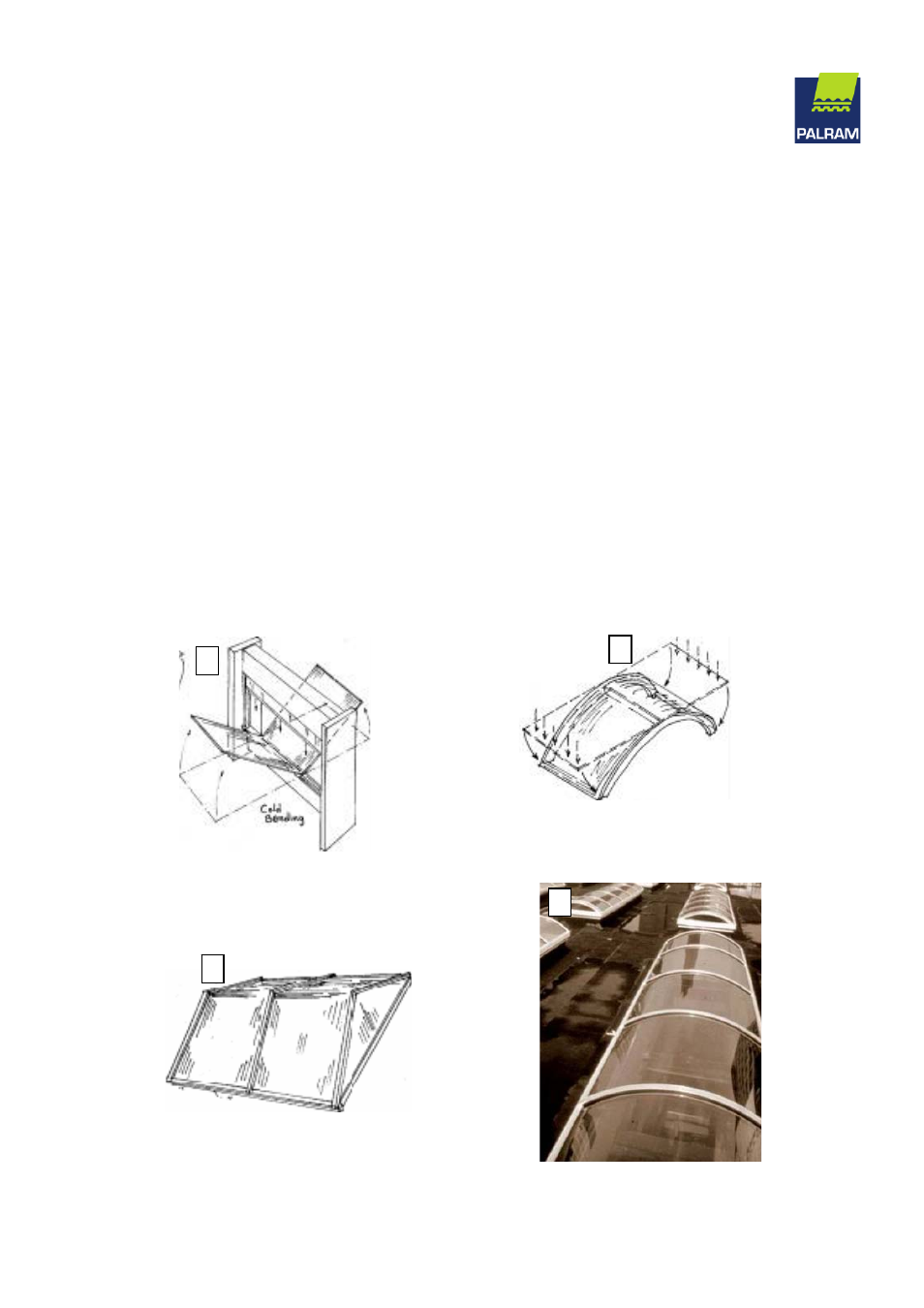

Figure 30 a,b. Cold Curved PALSUN Glazing

a. Cold Curving Process (Top)

b. Cold Curved Glazing in Skylights (Bottom)

Figure 31 a,b. Cold Bent PALSUN Glazing

a. Linear Cold Bending Process (Top)

b. Linear Cold Bent Glazing in a Skylight

(Bottom)

5. Principles of Planning & Engineering Design with PALSUN® Glazing:

a. Color, Tint, Light & Heat Transmission:

Almost any color & tint, in any rate of light transmission and thickness (up to 12mm) could be obtained ,

subject to minimal quantity order. In relatively small quantities only standard colors &

light-transmission rates could be supplied, subject to production runs availability & date.

b. Standard & Custom Sheet Dimensions:

Normal PALSUN sheets could be obtained in 3 standard dimension (in mm): 1250 x 2050,

1220 x 2440,

2050 x 3050. in relatively small projects these are the basic sizes the glazing panes should

be derived from, preferably with minimal or no waste.

In large scale PALSUN projects it is possible to order sheets of at any required dimensions, up to

2050mm width. Any length up to 12.00m could be obtained. However due to polycarbonate higher

thermal expansion rate we recommend the use of sheets no longer than 6.50 to 7.00m.

c. Forming PALSUN Glazing:

Important Note: This specific paragraph refers only to PALSUN. Currently available PALGARD sheets

should not be bent or curved, as these acts may break or damage the abrasion resistant silica coat!

1) Cold Forming:

a) Unlike glass, PALSUN glazing could be formed to a desired shape quite easily, by “Cold Curving”,

relying on PALSUN glazing’s natural flexibility, subject to minimal bending radius suitable to the specific

sheet thickness, or by “Linear Cold Bending”, using a mechanical “Brake Press” bending machine, similar

to the one used to bend flat sheet-metal.

a

a

b

b