Glazing guide – Palram PALGAR User Manual

Page 25

PALSUN® PALGARD™

Glazing Guide

25

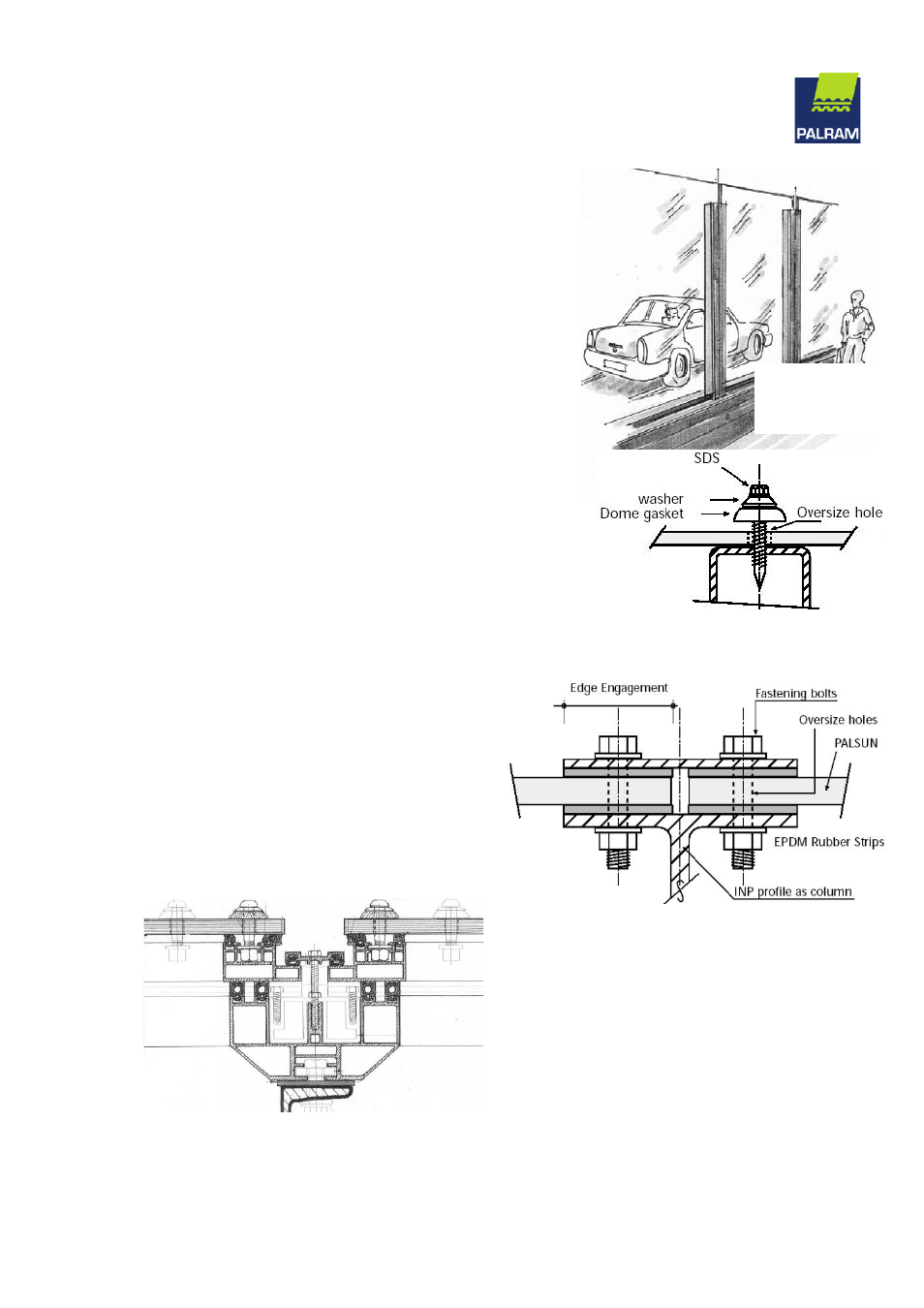

Figure 14. Typical

Partial Frame, 3

Sides Clamped

Glazing in a Sound

Figure 16. Typical Heavy-Duty Pressure

Distributing Bar Clamped Glazing, with

Bolts Fastening, in a Sound Barrier

Figure 15. Basic Screw Fastening with

Separate washers. Under the Glazing a

Thin EPDM Strip Padding

Figure 17. High-End, Heavy-Duty Aluminum

Sub-Frame with Separate Bolts & Washers

Fastened Glazing in a Variable Slope, Very

Shallow in Parts, New Olympic Stadium Roof,

Athens 2004 (Left)

c. PALSUN® Installation in a Partial Frame:

PALSUN could be installed clamped on three sides and frameless

on the fourth (generally top), and even clamped on two sides only.

This situation requires a thicker, more rigid glazing pane than that

installed in a full frame. Rate of thickness increase is to be

determined along 2 parameters: glazing size (particularly width)

and maximal anticipated wind-loads. Such a method is usually

used in vertical installations, many times in sound barriers.

d. Fastening PALSUN® with Bolts, Screws or Rivets:

A possible option, even if not truly recommended.

Installed in or on a supporting frame with bolts/screws through

pre-drilled oversize holes in the PALSUN sheet.

1) Holes would be 2mm larger in diameter than bolt or screw

used, to enable thermal expansion.

2) Each bolt/screw would be equipped with a

Ø

30-40mm rigid

metal (stainless/aluminum) washer, with a compatible

shaped soft EPDM gasket under the bolt head, on top side of

the glazing, to distribute the bolt’s pressure and pad the

fastener’s surrounding. (fig.15)

3) Tightening should be controlled & carefully executed, avoiding

excess local pressure on the glazing and distortion of the

gasket. Under no circumstances would an impact wrench be

used for the job.

4) A minimal distance of 2.5 times bolt/screw diameter, from glazing

edge to nearest hole edge, would be maintained, never less than

12mm.

5) Bolt fastening with pressure distribution clamping

bars, with compatible EPDM strip should be

preferred over fastening with separate oversize

washers. (Fig.16)

6) Fastening with bolts/screws would be selected,

mostly, in projects where sheer strength of

fastening has an obvious preference over

appearance, or when full length clamping profiles

may interfere with proper rainwater drainage

(shallow angled overhead skylights or roof glazing.

Fig. 17).