Part b, Glazing guide – Palram PALGAR User Manual

Page 15

PALSUN® PALGARD™

Glazing Guide

15

PART B.

INSTALLATION INSTRUCTIONS, DIRECTIVES & RECOMMENDATIONS

CLARIFICATION: Wherever PALSUN is mentioned - PALGARD is included, unless noted otherwise.

1. Flat PALSUN® & PALGARD™ Glazing Installation on Supporting Frames.

Supporting Methods & Appropriate Load Tables:

a. PALSUN glazing should be installed, similarly to glass, in or on a supporting framework, on which the

glazing would be supported on all its edges (4 sides clamped), on 3 sides or on two long edges (2 sides

clamped), with or without a glazing groove, and clamped to that frame with glazing bars or profiles.

b. PALSUN glazing could be installed, similarly to glass, in the “wet” or “dry” methods:

Basic installation procedures follow. Other variations of said methods are also used.

1) “WET” METHOD: A compatible polymeric putty is applied along the window sash, on all its perimeter

as a base for laying the PALSUN glazing, exactly like it is done in “wet” glass installation.. Then the glazing

is laid in place, leaving enough thermal expansion gaps around it. Glazing bars are then covered with

same putty and installed on the perimeter, fastened to the window frame, clamping the glazing. Finally,

compatible elastomeric sealing compound, (like silicone) is applied all around, inside and out, to assure

window’s impermeability.

Alternate version of that method uses “dry” rubber strips or spacers instead of putty, both in the sash and

on the glazing bar, as base layers, with final silicone application around glazing edges.

“Wet” method is used in wood or metal frames, in regular windows or on heavy-duty framing such as

sound barriers. The method is now less popular, and the “dry” method gets to be preferred.

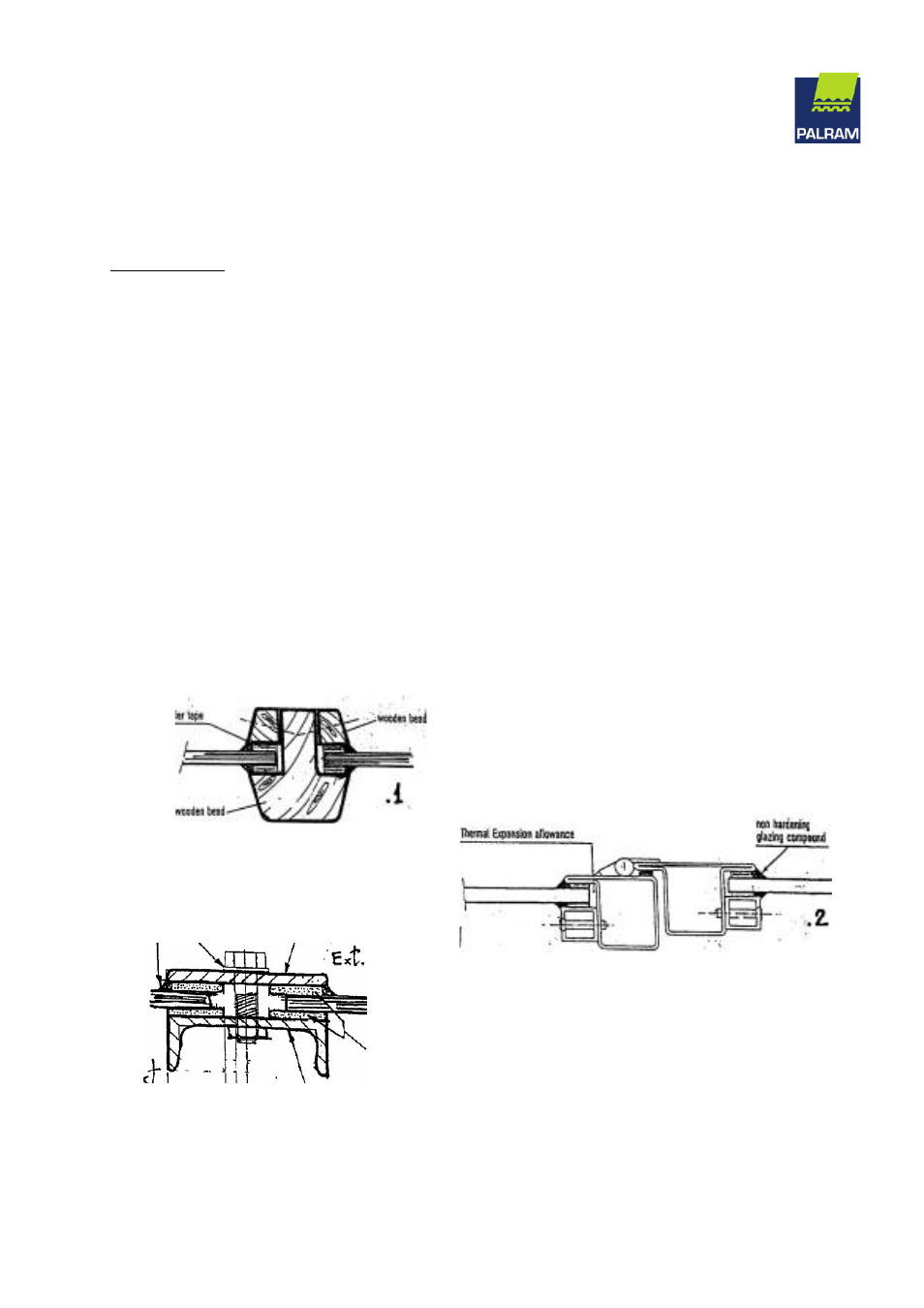

Figure 1. Typical Limited Size PALSUN

“Wet” Glazing with Putty, Glazing Clamp &

Peripheral Silicone Sealing Inside and Out.

Illustration Depicts Wood Framing. (Left)

Size is limited due to limited sash depth.

Figure 2. Typical Limited Size PALSUN “Wet”

Glazing with Rubber Strip Spacers, Glazing Clamp

& Peripheral Silicone Sealing Inside and Out.

Illustration Depicts Sheet Steel Framing. (Right)

Size is limited due to limited sash depth.

Figure 3. Typical Extended Size PALSUN “Wet” Glazing,

with Rubber, or XPE Strip Spacers both sides, Glazing

Clamp & external Peripheral Silicone Sealing. Illustration

Depicts Heavy-Duty Steel Frame, Suitable for Large Public

Structures (stadiums, sports arenas, Sound Barriers). (Right)

Extended Glazing Size due to wide Engagement Dept & High

Frame Rigidity .