Glazing guide – Palram PALGAR User Manual

Page 16

PALSUN® PALGARD™

Glazing Guide

16

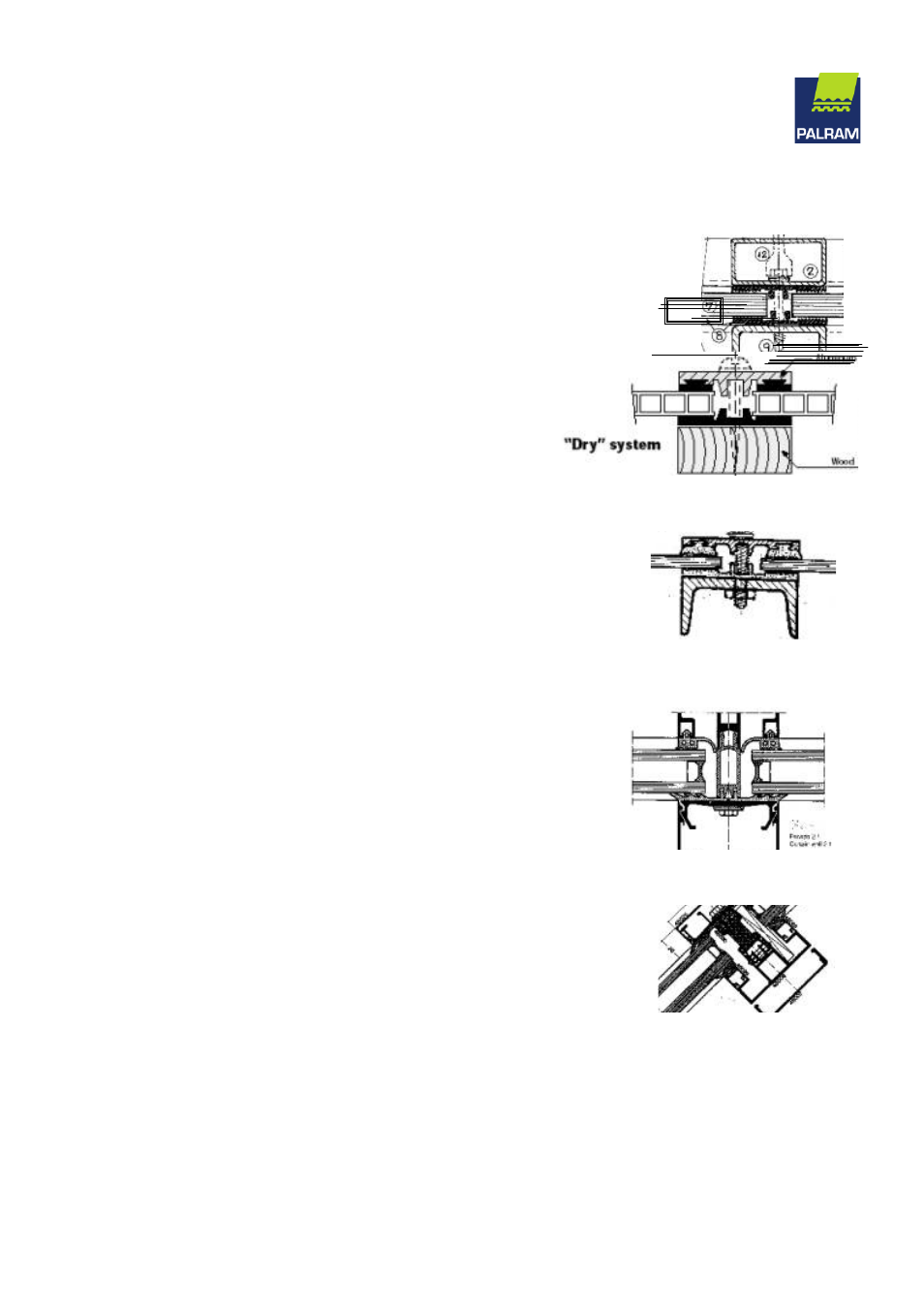

2) “DRY” METHOD:

Uses only “mechanical” means, such as

various profiles & bars, of wood, PVC but mainly metal ones, including

simple flat, bent, RHS profiles in regular steel or aluminum, or

specifically designated regular & stainless steel or aluminum profiles, with

specially made sealing strips & gaskets.

The method does not rely on chemical bonding or sealing of adhesive

pastes and compounds of any kind. Connections, fastening and sealing are

done by various types of fasteners or specially designed mechanical profiles with

details enabling connections of elements by special tongue &

groove design, material springiness and flexibility etc.

Impermeability & sealing are arrived at by careful design &

appropriate materials used, both of the rigid frame profiles

and resilient rubber gaskets of many types.

Professional design circles believe “Dry” method is “cleaner” &

more elegant in appearance, operates better (when designed

well), more durable and longer lasting than its “wet”

counterpart.

It also enables certain large-scale design options impossible or awkward

to execute in “wet” systems.

Basic idea of a “dry” glazing system, either vertical or sloped (“horizontal”)

is laying the glazing pane on a springy EPDM rubber or similar compatible

glazing strip attached to the supporting frame along the

window sash, usually on four sides, and clamp it with

appropriate glazing bars or profiles, also equipped with suitable

sealing strips, so those clamps tighten the glazing fully on all its

perimeter, with the external gaskets squeezed tight to the glazing,

sealing it against water & dirt infiltrating.

The system should be designed so that should some water succeed

to penetrate this first defense line they should accumulate and drain

downward through internal channels in the frame (second defense

line), and should not reach the internal glazing gaskets (last defense).

This is especially important in skylights & sloped roofing, where

rainwater stands more chance of accumulating & infiltrating.

Similar glazing systems exist for glass skylights & curtain-walls, all around

the world, and a few could also be used for limited thickness & spacing

solid polycarbonate glazing. The main requirement of any optional profile

series selected is deep enough window sash which enables at least15 to

20mm edge engagement depth plus 2-3mm gap for thermal expansion

each side.

Figure 6. Typical Glazing with Heavy

Duty Steel & Aluminum Profiles &

Designated EPDM rubber Glazing

Figure 4. Typical Glazing

with Simple RHS Steel

Profiles & Designated

EPDM rubber Glazing Strips

Figure 5. Typical Glazing with Combined

Wood & Aluminum Profiles and

Designated EPDM rubber Glazing Strips

Figure 8. Existing Aluminum & Glass Sloping

Skylight system Optional for PALSUN Glazing

of Limited Dimensions

Figure 7. Existing Curtain Wall Aluminum

& Glass System Optional for PALSUN

Glazing of Limited Dimensions