Glazing guide – Palram PALGAR User Manual

Page 23

PALSUN® PALGARD™

Glazing Guide

23

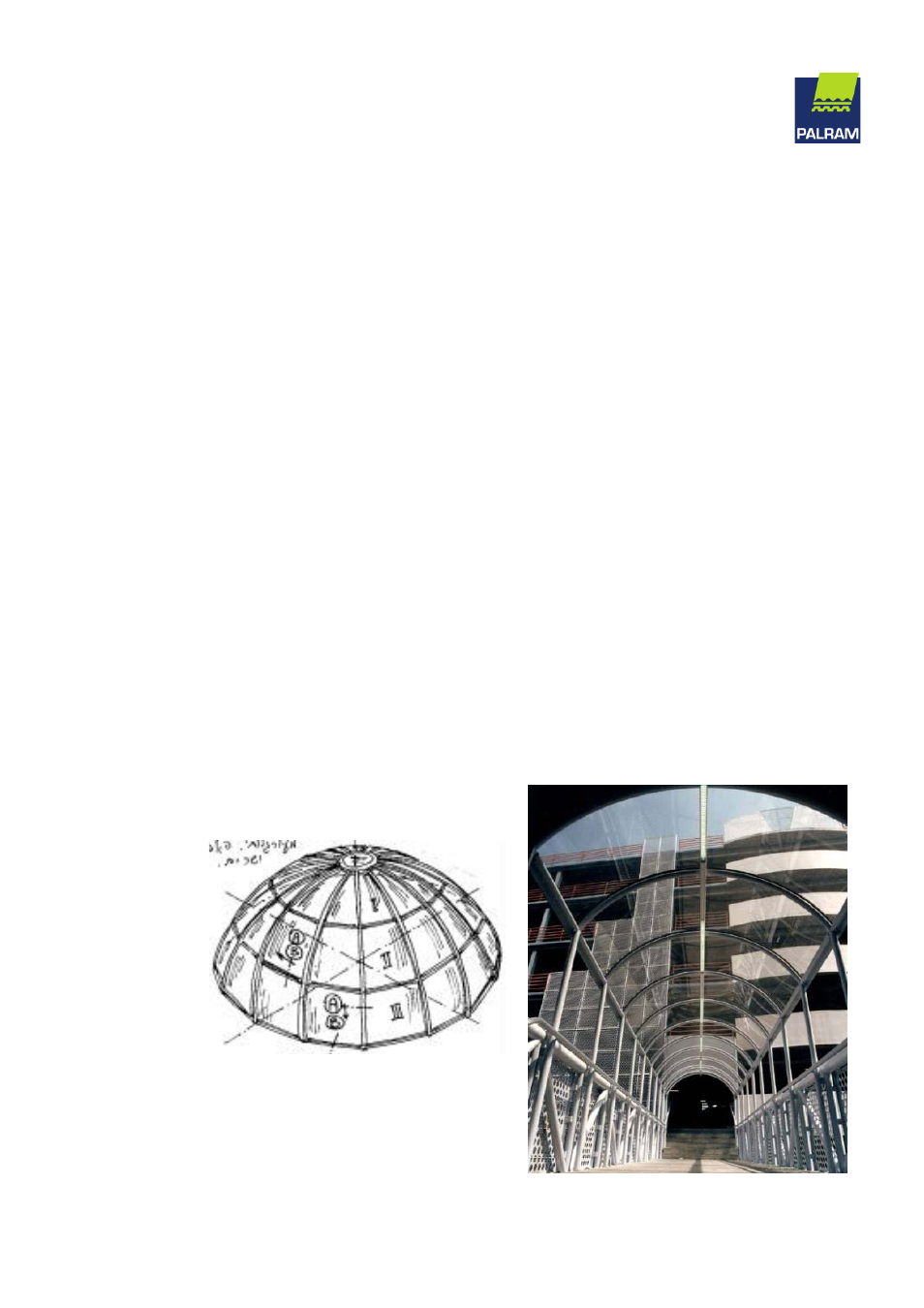

Figure 12. Diagonal Look

through Curved PALSUN

Vaulted Walkway

Figure 11. Schematic

Sketch of PALSUN

Glazed Dome Skylight

3. General Indications for Curved PALSUN Installation:

a. Clamping: Curved PALSUN glazing should be installed almost identically to flat installation, similarly to

glass, in or on an arched supporting framework, on which the glazing would be supported, adapted &

clamped on two or four of its edges, with or without a glazing groove. The clamps (glazing bars or

profiles) should also be curved by simple hand pressure (in simple, shallow curves) or by designated roll-

forming in deep curves and/or complex profiles.

b. “Wet” or “Dry”?: PALSUN curved glazing could be installed similarly to flat glass or PALSUN, in “wet”

or “dry” methods.

Basic installation procedures and details are shown on the flat PALSUN installation

previously depicted. Variations of said methods are also used.

c. Stronger when Curved!: PALSUN, like any sheet shaped material, gets stronger & more rigid when it is

curved. Strength and rigidity increase as the PALSUN sheet curve (“radius”) nears the minimal permitted

bending radius (deepest allowed curve), as can be observed in the curved glazing load table.

d. Minimal Curving Radius: Essentially, PALSUN minimal permitted curving radius is calculated as 175

times the sheet thickness. This rate was arrived at after a careful testing, which showed that at this

minimal radius the sheet isn’t damaged and still retains its typical properties. A sheet could be bent to an

even smaller radius, but undue internal stresses created by excess curving would lead to crazing, fracture

& eventual failure.

e. “Cold” Vs. Thermal Curving”: All the above refers to “cold” curving, i.e. forming the sheet at average

ambient temperature by forcing it to a curved shape relying on polycarbonate’s natural flexural

properties.

PALSUN glazing could be curved to an even smaller radius by a thermo-forming process without any ill-

effects of excess stresses. A costly procedure limited by size & availability of required thermoforming

equipment.

f. Spring Back: Cold curved PALSUN is springy, pushing back trying to retain its original shape. The

thicker and shorter the sheet the more difficult it is to bend it and keep that shape. This must be taken

into consideration both at the design and at execution stages. Proper structural framework and glazing

bars should be selected to withstand the loads.