Ntellisys, Daptive, Ressure – Nor-Cal IQ+ Adaptive Pressure Controller User Manual

Page 17: Ontrollers, 1 - how to configure iq+ for your system, Devicenet commands, Continued), System configuration commands

1

Call toll free

800-84-4166

or 530-842-4457

•

FAX 530-842-9130

I

ntellIsys

A

dAptIve

p

ressure

C

ontrollers

IQ+ OP-LIT 9/08

6.1 - How to Configure IQ+ for your System

(continued)

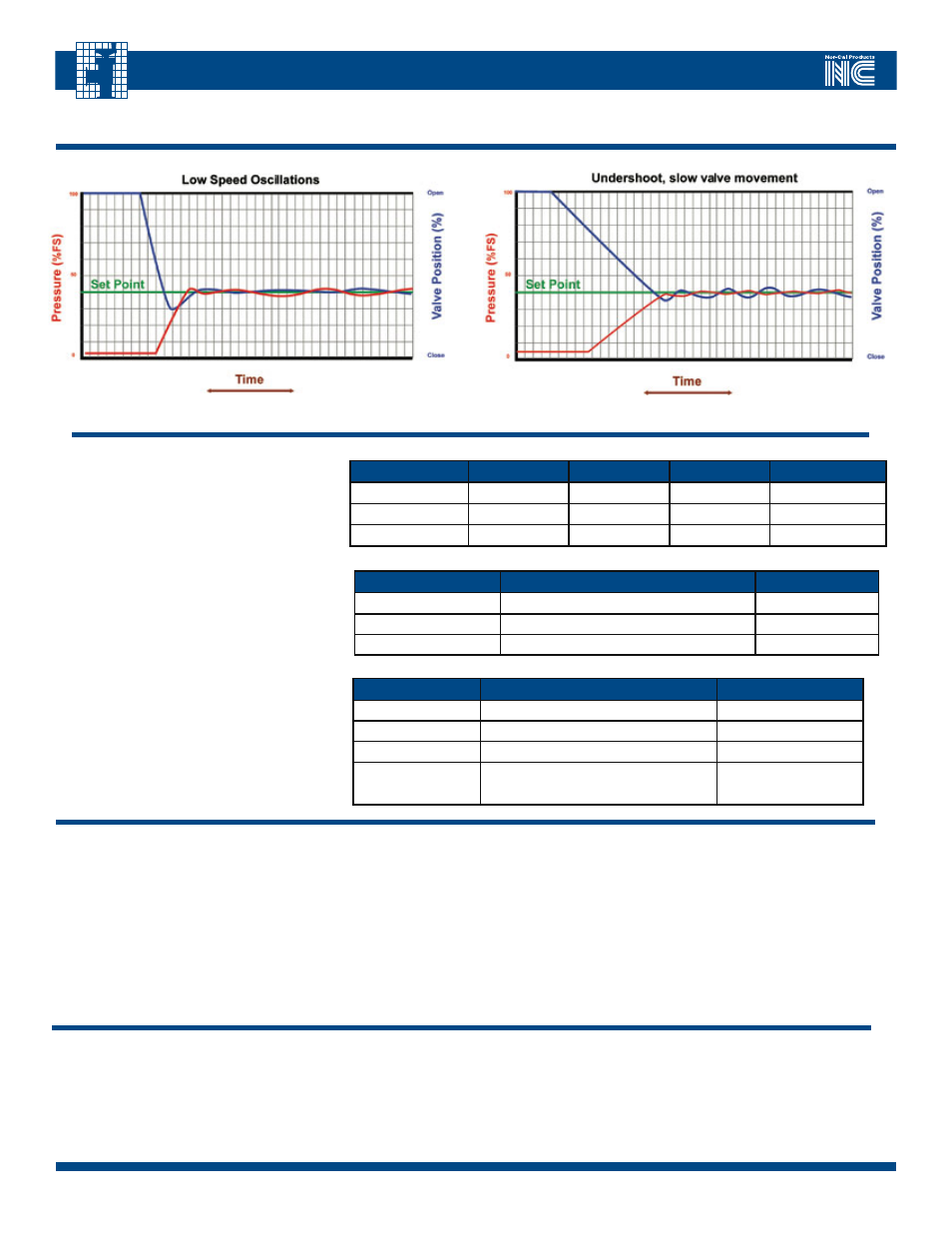

FIGURE 6.4 – SPEED TOO HIGH

FIGURE 6.5 – SPEED TOO LOW

System Configuration Commands

DeviceNet Commands

Class ID 33

hex

Instance ID 1 (Process Control)

attrIBute Id hex

acceSS code

name

Format

value

64

OE (get) 10 (set)

Volume

INT

1-100, default = 0

65

OE (get) 10 (set)

Delay

INT

0-10, default = 0

66

OE (get) 10 (set)

Speet

INT

1-100, default = 100

TAbLE 6.4 – DEvICENET COmmANDS

TAbLE 6.5 – RS-232 SERIAL COmmANDS

SerIal command

deScrIPtIon

reSPonSe

SVxxx

Set Volume where xxx is a number from 1 to 100

PID VOLUME: xxx

SDxxx

Set Delay where xxx is a number from 1 to 10

PID DELAY: xxx

SSxxx

Set Speed where xxx is a number from 1 to 100

PID SPEED: xxx

TAbLE 6.6 – RS-232 SERIAL REQUESTS AND RESPONSES

SerIal requeSt

deScrIPtIon

reSPonSe

RV

Requests Volume value

PIC VOLUME: xxx

RD

Requests Delay value

PID DELAY: xxx

RS

Requests Speed value

PID SPEED: xxx

RPI

Requests values of Volume, Delay and Speed

SPEED: xxx

VOLUME: xxx

DELAY: xxx

A

Record the current Volume, Delay, and Speed parameters.

b

For serial interface set the serial port speed 100ms or less. For Devicenet

set to 50ms. Or less.

C

Start pressure control at a process critical set point, or a set point halfway

between the system maximum and minimum process pressure set points.

With the system GUI or a PC that can graph data observe the pressure and

valve movement.

D

If the pressure parameters need adjusting stop pressure control and Open

the valve. Enter new value for pressure parameters.

Parameters are adjusted in this order: volume

Delay

Speed (not normally adjusted)

E

If the pressure response is satisfactory, input a set point at the system

minimum pressure or another process critical set point. Make adjustments

as necessary. If a change was made re-check pressure set point in step C.

F

If the pressure response is satisfactory, input a set point at system maxi-

mum pressure. Adjust if necessary. If a change was made re-check set

points in steps C and D.

G

Record new parameters for Volume, Delay, and Speed.

Setting Volume, Delay and Speed

Setting Volume, Delay and Speed (Example)

The system has a 1 Torr pressure gauge. The pressure control range is

20mTorr - 600 mTorr. The process critical range is 120mTorr.

A

Record values of Volume, Delay, and Speed.

b

Start pressure control with a set point 120mTorr. Adjust the parameters if

necessary.

C

Start pressure control with a set point of 20mTorr. Adjust parameters if

necessary. If any changes are made then re-check the 120mTorr set point.

D

Start pressure control at 600mTorr.. Adjust the parameters if neces-

sary. If any changes are made then re-check the 120mTorr and 20mTorr set

points.

E

Record new values of Volume, Delay, and Speed.