4 installation – Glow-worm 56/3 Back Boiler User Manual

Page 9

9

221724B

4 Installation

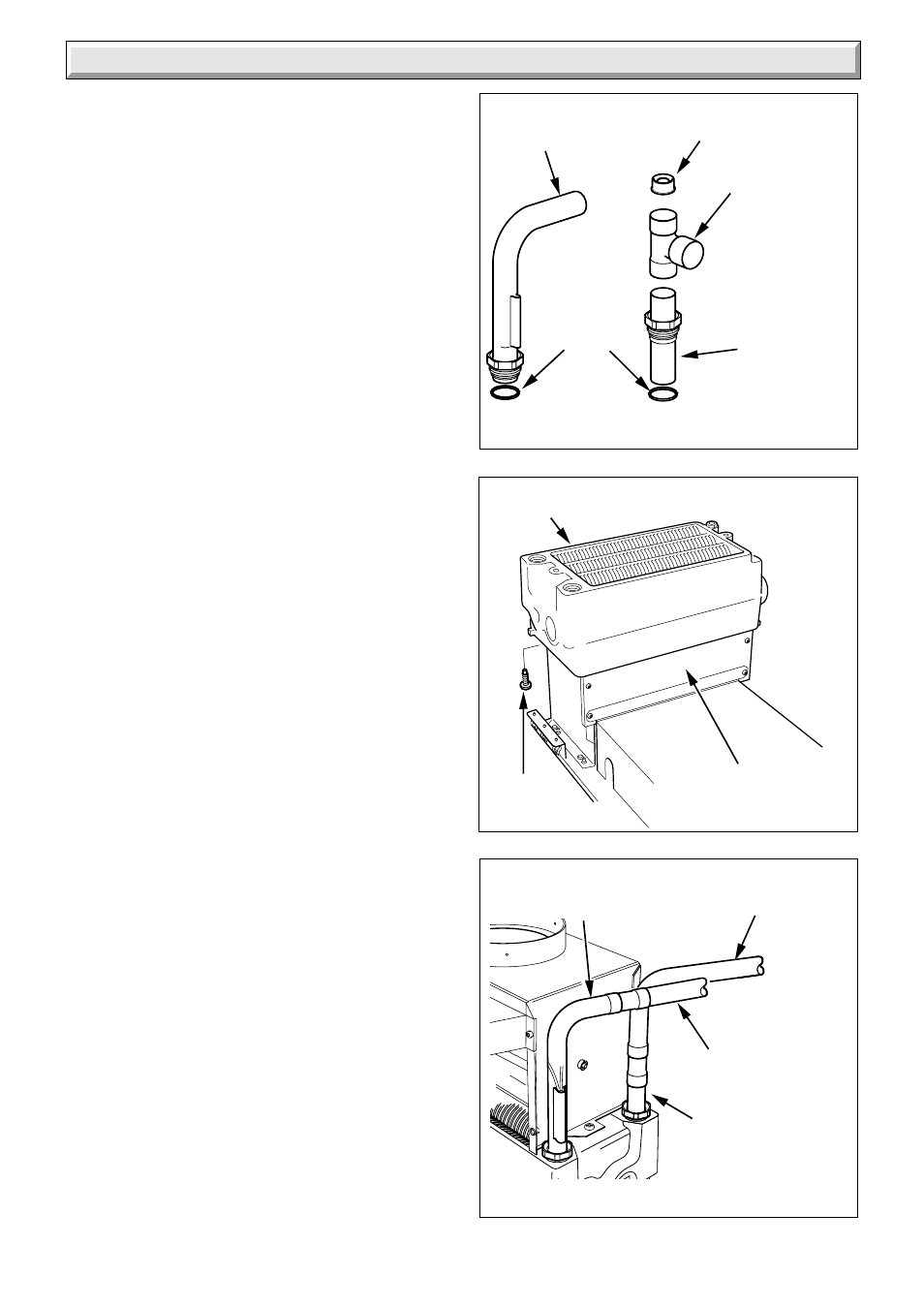

Diagram 4.2

Diagram 4.3

6839

HEAT

EXCHANGER

SECURING

SCREWS (4)

COMBUSTION

CHAMBER

6840

22mm

FLOW

22mm

RETURN

Diagram 4.1

6254

UNEQUAL

TEE PIECE

SEALING

WASHERS

INJECTOR

22mm COPPER PIPE

SUPPLIED WITH

APPLIANCE

(Do not cut)

22mm COPPER

PIPE SUPPLIED

WITH APPLIANCE

(Do not cut)

22mm COPPER PIPE

SUPPLIED WITH

APPLIANCE

(Do not cut)

22mm

COPPER

PIPE

SUPPLIED

WITH

APPLIANCE

(Do not cut)

Pumped Heating and Hot Water

4.1 Preparation

Remove draught diverter assembly, flueway baffles and

fittings pack from carton.

Check contents of fittings pack against packed list.

Remove back boiler body assembly from carton.

4.2 Water Connections

IT IS EXTREMELY IMPORTANT THAT NO SERVICE

PIPES ARE ROUTED IN FRONT OF THE BOILER. If the

builder’s opening was previously used for solid fuel all

pipework within should be protected with PVC tape or equal.

Pipework passing through walls of the opening should be

sleeved and made good.

The two heat exchanger connections are supplied in the

fittings pack and MUST be used, see diagram 4.1.

NOTE: Take care when soldering the copper connections not

to damage the sealing washers.

4.3 Pumped Heating with Gravity Domestic

Hot Water

NOTE: The draught diverter assembly and capillaries are

shown to aid plumbing, but would not be fitted at this stage.

All pipework must comply with the current issue of BS5546.

The domestic hot water flow and return pipes must be

28mm.

Refer to diagrams 1.3 and 1.4 for a diagrammatic layout.

If it is necessary to route pipework from both sides of the

builder’s opening, it is recommended that the heat exchanger

is positioned on the combustion chamber so that the gravity

circuits exit on the same side as the boiler connections.

If the heat exchanger connections are opposite hand to that

required, the heat exchanger can be turned, as follows,

remove the four screws securing the heat exchanger to

combustion chamber, see diagram 4.2. Turn heat

exchanger, refit the four screws.

It is recommended that pumped heating connections are pre-

piped as in diagram 4.4.

Note: The diagram 4.4 shows two methods “A” and “B” of

plumbing the flow pipe.

The central heating return must have the injector fitted on

both methods “A” and “B”, see diagram 4.4 for fitting the

injector.

4.4 Pumped Heating and Hot Water

NOTE: The draught diverter assembly and capillaries are

shown to aid plumbing, but would not be fitted at this stage.

Refer to diagram 1.5 for a diagrammatic layout.

If it is necessary to route pipework from both sides of the

builder’s opening it is recommended that the heat exchanger

is positioned on the combustion chamber such that the flow

pipe exits on the same side as the boiler connections.

It is recommended that the pumped return is pre-piped as in

diagram 4.3.

If the heat exchanger connections are opposite hand to that

required, turn in the same manner as described in Section

4.3 paragraph 6.