1 general – Glow-worm 56/3 Back Boiler User Manual

Page 5

5

221724B

C

L

BOILER

Diagram 1.4

1 General

1.13 BSI Certification

This appliance is certificated to the current issue of BS6332

Part 1 invoking the current issue of BS5258 Part 8 for safety

and performance. It is, therefore, important that no alteration

is made to it without permission, in writing, from Hepworth

Heating Ltd.

Any alteration that is not approved by Hepworth Heating Ltd.,

could invalidate the BSI Certification of the boiler, warranty

and could infringe the current issue of the Statutory

Requirements.

CE Mark

The CE mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the Laws

of the Member States relating to appliances burning gaseous

fuels.

2. Directive 73/23/EEC on the harmonization of the Laws of

the Member States relating to electrical equipment designed

for use within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws

of the Member States relating to electromagnetic

compatibility.

This boiler meets the requirements of Statutory Instrument,

No. 3083, The Boiler (Efficiency) Regulations, and therefore

is deemed to meet the requirements of Directive 92/42/EEC

on the efficiency requirements for new hot water boilers fired

with liquid or gaseous fuels.

Type test for purposes for Regulation 5 certified by: Notified

body 0086.

Product/production certified by: Notified body 0086.

1.14 Inhibitor

Attention is drawn to the current issue of BS5499 and

BS7593 on the use of inhibitors in central heating systems.

If an inhibitor is to be used, contact a manufacturer for their

recommendations as to the best product to use.

If using in an existing system take special care to drain the

entire system, including the radiators, then thoroughly

cleaning out before fitting the boiler whether or not adding an

inhibitor.

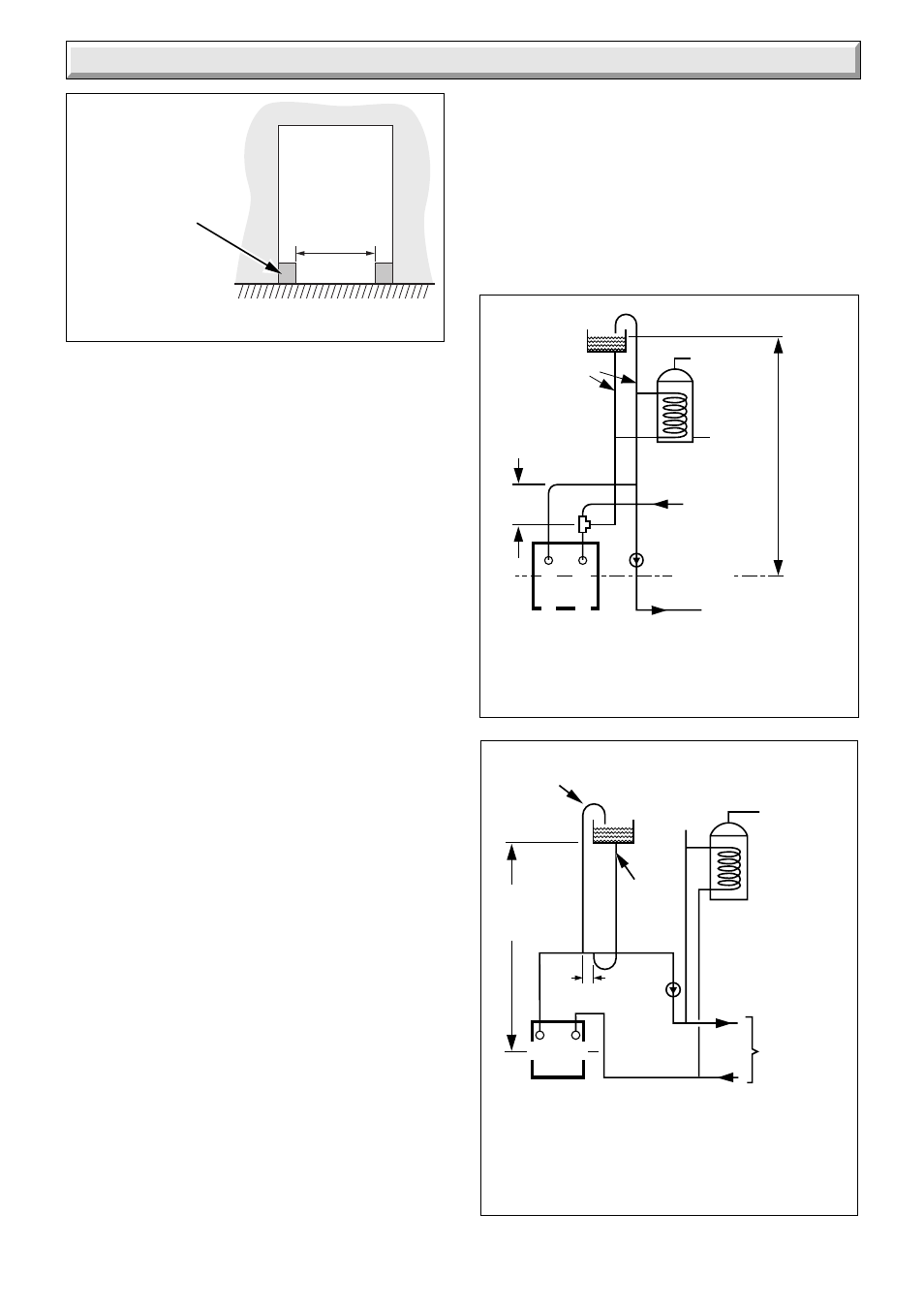

6242

BOILER

22mm

CENTRAL

HEATING

RETURN

28mm

DISTRIBUTOR

TUBE IN RETURN

CONNECTION

22mm

CENTRAL

HEATING

FLOW

FLOW

RETURN

INDIRECT

CYLINDER

27 METRES

MAXIMUM

IMPORTANT

DIMENSION

NOT LESS

THAN 145mm

C

L

PUMPED HEATING &

GRAVITY DOMESTIC HOT

WATER (DIAGRAMMATIC)

FULLY PUMPED SYSTEM

(DIAGRAMMATIC)

Diagram 1.5

The COLD FEED PIPE may be connected to the flow

pipe, adjacent to the open vent pipe as shown .

(THERE MUST ALWAYS BE A COLD WATER PATH

TO THE RETURN CONNECTION Of THE BOILER.)

22mm MIN

OPEN VENT

INDIRECT

CYLINDER

MANUAL

AIR VENT

1 metre MIN

27 metres MAX

15mm

COLD

FEED

PUMP

HEATING

CIRCUIT

150mm MAX

7218

* CORNER IN-FILL

(not required to be

full depth of opening)

405 mm. MIN.

Diagram 1.3

6408

FRONT

OPENING