6 commissioning – Glow-worm 56/3 Back Boiler User Manual

Page 18

18

221724B

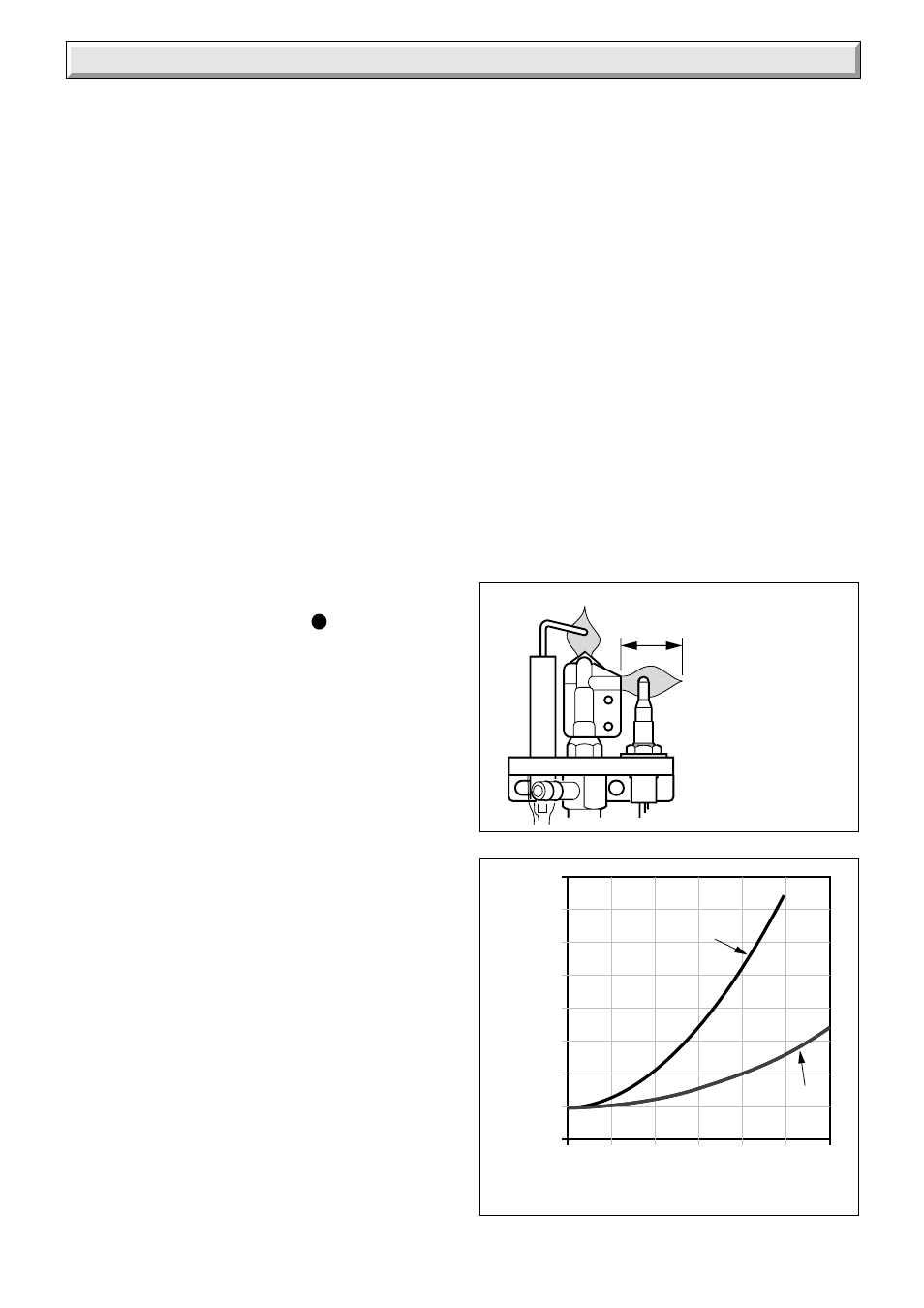

Diagram 6.3

PRESSURE LOSS (mm head of water)

FLOW RATE (litres / minute)

700

With injector

fitted

Without

injector fitted

600

500

400

300

200

100

0

5

10

15

20

25

30

0

-100

7296

6 Commissioning

If the boiler is used with a Miami 3 or Melody 3 fire front it is

permitted to increase the output to 16.4 kW (56000) Btu/h).

If adjustment is required, TEN MINUTES after lighting,

remove cover “G” and turn adjustment screw, anti-clockwise

to suit system design heat input.

Should any doubt exist, the gas rate should be checked at

the gas meter.

The rate of the back boiler should be within the range,

For Saxony, Black Ash, Brown Ember:

1.15m

3

/h (40.5ft

3

/h) to 1.86m

3

/h (65.7ft

3

/h)

For Melody, Miami:

1.15m3/h (40.5ft

3

/h) to 1.94m

3

/h (68.5ft

3

/h)

Note, if the gas rate is checked, make sure that all other gas

appliances and pilot lights are turned off.

Turn control thermostat knob “A” anti-clockwise to “O” “Off”

position. Remove pressure gauge and replace test point

screw ensure a gas tight seal is made. Replace governor

cover screw “G”.

Relight the back boiler by turning thermostat knob “A”

clockwise to “MAX”.

Use the self adhesive arrow from the fittings pack and stick it

against the relevant heat input figure on the Data Label.

6.2 Testing the Back Boiler Controls

To check the operation of the flame failure device proceed as

follows:

With the main burner alight, slightly push in gas control knob

“B” and then turn it fully clockwise until

is against the

setting point. This will put out the main and pilot burners.

Note, relighting will not now be possible as the safety device

in the gas valve has been activated.

Check that the flame failure device closes within 60 seconds,

indicated by a click from the valve.

DO NOT ATTEMPT TO RELIGHT UNTIL AT LEAST 3

MINUTES HAVE GONE BY.

Relight the pilot and main burner as described in the relevant

part of Section 6.1.

Check that the boiler thermostat and any external controls

operate the back boiler correctly.

6.3 Clearance of Products

A clearance of products (spillage) test must be carried out

after installation of the back boiler and its fire.

Before fitting the fire check that the heat exchanger baffle is

fitted and seated correctly, see Section 4.8.

Details of the necessary tests to be carried out will be found

under “TEST FOR CLEARANCE OF PRODUCTS” in the fire

Installation Instruction Booklet.

Note: This test must only be carried out after the fire front

has been fitted to the back boiler unit.

6.4 Commissioning the System

Set all controls to operate the heating system. Adjust

circulating pump and balance the system to give a

temperature drop across the boiler of 11

o

C (20

o

F). At the

appropriate flow rate, the resistance of the back boiler can be

found by reference to diagram 6.3.

There should be no undue noise in the pipework or heat

emitters. There must be NO pumping over of water or entry

of air at the open vent pipe above the feed and expansion

cistern.

Make sure the back boiler thermostat knob “A” is turned

clockwise to “MAX” against the setting point, allow the water

to reach maximum working temperature. Examine the

system for water soundness.

Turn the thermostat knob “A” anti-clockwise to “Off” and

rapidly drain the system whilst still hot, to complete the

flushing process.

Refill the system, vent and check again for water soundness.

Fire Front Installation and Servicing Instructions are packed

with the fire.

Diagram 6.2

6357

13mm

FLAME

DIMENSION