6 commissioning – Glow-worm 56/3 Back Boiler User Manual

Page 17

17

221724B

6 Commissioning

6.1 Commissioning the Back Boiler

Before commissioning the back boiler, the whole of the

system should be thoroughly flushed out with cold water with

the circulation pump removed. Replace the pump, fill the

system and examine for water soundness. Vent air from the

system and pump.

The back boiler unit is fitted with a flue blockage safety

device, which will shut it down if there is a lack of oxygen.

The principle by which this operates is that when there is a

depletion of oxygen resulting from a build up of combustion

products, flame on the pilot light will become unstable and lift

up off the thermocouple. This will deactivate the mag unit in

the gas control valve, cutting off the gas supply.

If the back boiler unit shuts down frequently for no apparent

reason the first things to be checked are the chimney and air

inlets into the room. Any problems found must be put right,

by a competent person, and a full operational test carried

out before the back boiler unit is used again.

The flue blockage safety device incorporates the electrode,

thermocouple and pilot assemblies.

The flue blockage safety device MUST NOT be adjusted or

disconnected. It must be serviced strictly in accordance with

the instructions in this book. Any unauthorised interference

could result in the device failing to operate, creating a

potentially dangerous situation. If replacing, use only the

correct and approved part.

CAUTION: The following work should be carried out by a

competent person.

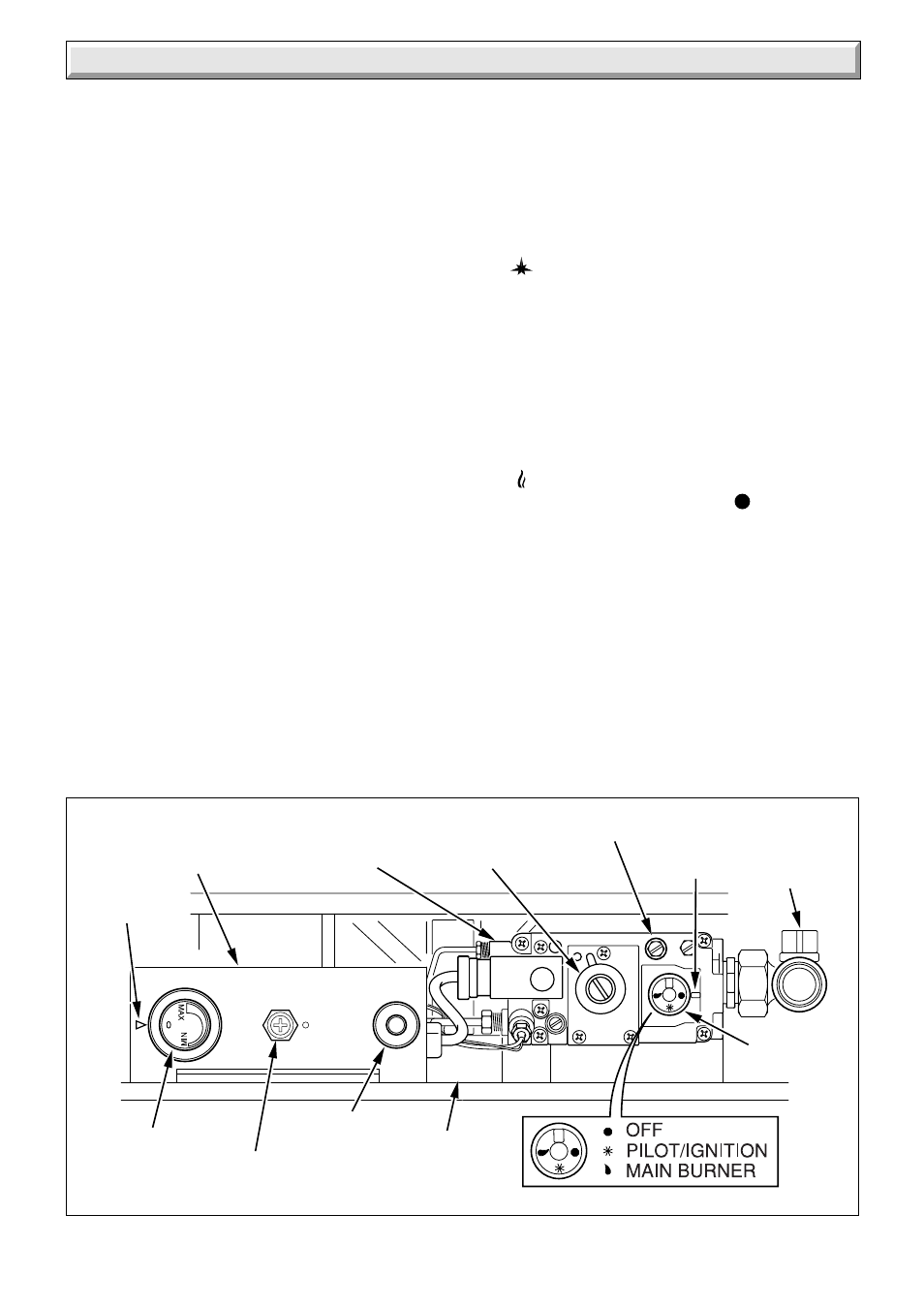

Identify the back boiler controls by reference to diagram

6.1.

Note: Overheat cut-off, see diagram 6.1 is applicable only

where the back boiler unit is incorporated in a sealed water

system.

Open all windows and put out any naked lights, cigarettes

etc.

Test the gas supply for soundness. Purge air in accordance

with the current issue of BS6891.

Check that the electrical supply to the back boiler is switched

off.

Set the thermostat control knob “A” to “Off” that is, fully anti-

clockwise.

Make sure the thermostat phial is fitted correctly, see

diagram 5.4.

Remove the back boiler burner pressure test screw “H” and

connect a suitable pressure gauge.

Turn gas service cock “K” to Back Boiler only “On” position,

see diagram 4.12.

Push in slightly and turn gas control knob “B” anti-clockwise

until

is against the setting point, now push fully in and

hold, at the same time press and release piezo button “D”

until the pilot burner lights.

Note, at this stage air may be present in the pilot supply so

this operation may need to be repeated.

When the pilot burner lights, keep gas control knob “B” fully

pushed in for about 15 seconds. If the pilot burner fails to

stay alight, repeat the lighting procedure but now keep the

control “B” knob pushed in for a little longer.

Check that the pilot flame is stable and has a length as

shown in diagram 6.2.

Push in slightly and turn gas control knob “B” anti-clockwise

until

is against the setting point.

If the gas control knob “B” is turned until

is against the

setting point, a safety lock prevents it being turned on again

until the thermocouple has cooled. NO ATTEMPT SHOULD

BE MADE TO TURN THE CONTROL KNOB “B” UNTIL AT

LEAST 3 MINUTES HAVE GONE BY.

Switch on electrical supply and set any remote controls that

is, clock, thermostats and the like, for heating. Refer to

control manufacturers’ instructions for specific details.

Turn thermostat knob “A” clockwise until “MAX” is against the

setting point. The main burner should now light.

Test for gas soundness using a suitable leak detection fluid.

The back boiler is supplied preset to a maximum heat output

setting of 15.8 kW (54000 Btu/h) but may be adjusted to suit

design requirements.

This value 15.8 kW must not be exceeded when using the

boiler in combination with a Brown Ember 3, Black Ash 3 or

Saxony 3 fire front.

Diagram 6.1

6822

CONTROL BOX

CONTROL

THERMOSTAT

KNOB “A”

BURNER PRESSURE

TEST POINT “H”

GAS

CONTROL

VALVE “J”

SETTING

POINT “C”

GAS

CONTROL

KNOB “B”

GOVERNOR

ADJUSTMENT

COVER SCREW “G”

PIEZO UNIT

BUTTON “D”

BOILER DATA

BADGE “E”

POINTER

“F”

GAS

SERVICE

COCK “K”

OVERHEAT

CUT-OFF DEVICE

(sealed systems only)