3 flue and ventilation, Back boiler unit – Glow-worm 56/3 Back Boiler User Manual

Page 7

7

221724B

3 Flue and Ventilation

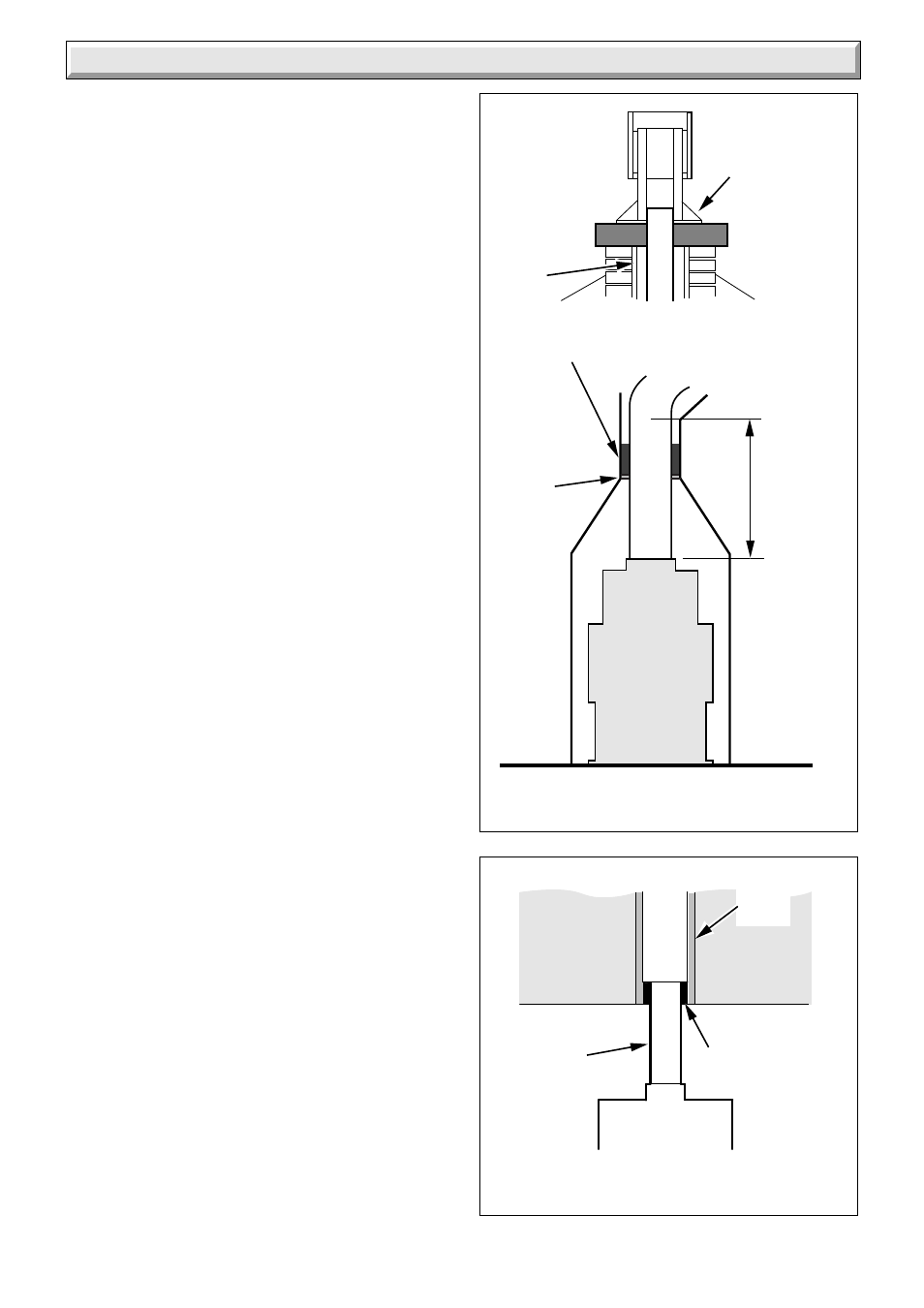

Diagram 3.1

3.1 General

The general recommendations of the current issue of

BS5440 Part 1 should be followed.

In all cases the flue should be lined, preferably with a flexible

liner.

It is essential that the flue has an equivalent height of at least

2.5m (8.2ft) measured from the flue connection on the

appliance. The first 600mm, at least, above the draught

diverter must be vertical.

The flue socket is designed to take flue pipe to BS567. If

flue pipe conforming to a different standard is used a suitable

adapter must be fitted and secured to the flue socket.

A flexible flue liner may be used, with connection to the back

boiler flue socket made with a short vertical piece of flexible

liner, see diagram 3.2.

The existing flue may not be completely sound.To prevent

any possibility of leakage, additional sealing MUST be

carried out between the base of the chimney and the flue

liner.

The end of the liner at the chimney top must be adequately

sealed and clamped, using proprietary fittings suitable for the

flue liner used, see diagram 3.1.

The flue should, preferably, end above ridge height but at

least above the eaves of a pitched roof. Use a certificated

terminal.

If the flue is to pass through or near any combustible material

it should be installed in accordance with the current issue of

BS5440 Part 1. If in doubt seek advice from the local gas

undertaking or Hepworth Heating Ltd.

3.2 Existing Chimney

An existing brick chimney must be thoroughly swept and all

debris cleared away before lining.

Remove any register plates, dampers and the like.

Alternatively it may be locked in the open position.

A flexible flue liner is preferred but a rigid liner may be used,

with connection to the back boiler flue socket made with a

short vertical piece of flexible liner, see diagram 3.2.

Any air supply that enters the builder’s opening other than by

the front opening, that is underdraught openings and the like

must be completely sealed off.

The sealing plate also prevents debris falling and gives the

flue better insulation, reducing the possibility of

condensation, see diagram 3.1.

Check the flue system efficiency before installing the back

boiler.

3.3 New Chimney

A newly built chimney can be lined with a moisture resistant

lining, such as salt glazed pipe, of an appropriate diameter

as specified in the Building Regulations

In the case of a salt glazed lined flue, it is recommended that

a short vertical length of flue pipe, preferable flexible metallic

be used, fixed and sealed to the back boiler flue socket,

made good with approved packing and parged with fire

cement, see diagram 3.2.

BACK

BOILER

UNIT

6197

SEALING AND

CLAMPING

PLATE

AIR

SPACE

150mm (6in) plug of Mineral Wool or similar

600mm

Diagram 3.2

7194

APPROVED

SEAL

FLEXIBLE

LINER

BACK BOILER

RIGID

FLUE

LINER

Existing Flue Fitted with

Approved Lining

SEALING

PLATE