5 electrical wiring – Glow-worm 56/3 Back Boiler User Manual

Page 14

14

221724B

5 Electrical Wiring

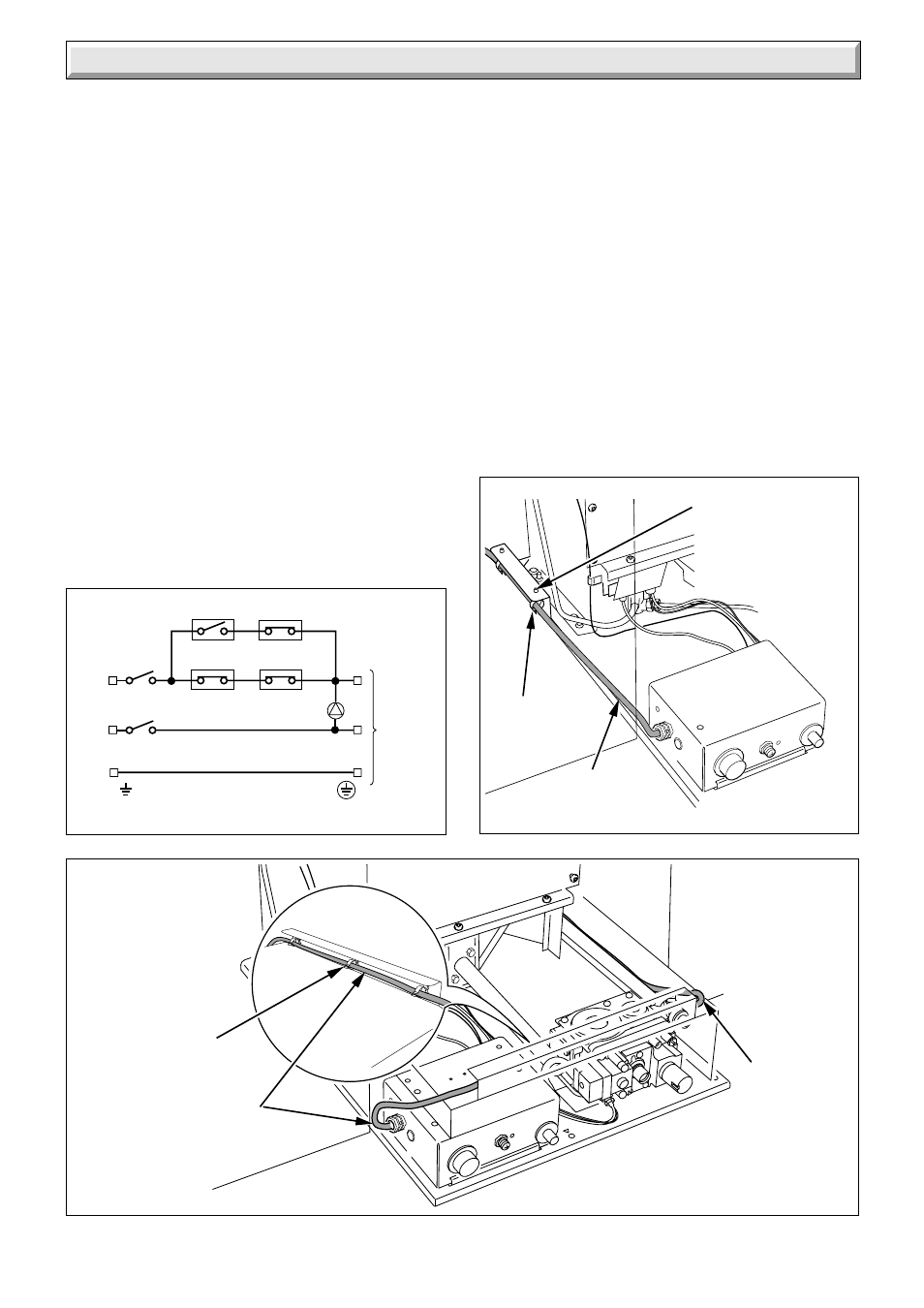

Diagram 5.2

Diagram 5.3

6878

6871

5.1 General

WARNING. This boiler must be earthed.

ISOLATE THE ELECTRICAL SUPPLY BEFORE DOING

ANY WIRING

All of the electrical installation must be correctly earthed and

be in accordance with the current issue of BS7671 and be

carried out by a competent person.

The boiler electrical supply is 230V~ 50Hz, fused at 3A. A

double pole isolating switch, having a minimum contact

separation of 3mm in both poles should be used.

The boiler will only require a permanent live if a fire front with

lights or ignition is to be fitted.

External controls are connected to the live 'Ls' terminal on

the 3 way terminal block, as an example see diagram 5.1.

Supply cable should be (85

o

C) PVC insulated type to the

current issue of BS6500 Table 16, not less than 0.75mm

2

(24/0.20mm).

NOTE: The supply to the boiler and any remote control must

be through the same isolating switch or plug and socket.

It is preferable to have the boiler electrical supply cable

entering the builder’s opening at the left.

If the cable has to be routed down the left hand side of the

combustion chamber the heat shield assembly supplied in

the fittings pack must be used and the cable routed through

the clips, see diagram 5.2.

HEAT

SHIELD

ASSEMBLY

ELECTRICAL

SUPPLY

CABLE

CABLE

CLIPS (3)

ELECTRICAL

SUPPLY

CABLE

Diagram 5.1

6452

Froststat

Pipestat

Roomstat

Programmer

Pump

Ls

N

E

L

N

E

Double

Pole

Switchspur

3 Way

terminal

block at

Appliance

If right hand access is required fit the three clips from the

fittings pack to the combustion chamber extension and route

the cable down the right hand side of the combustion

chamber. Keep the cable well clear of hot surfaces, see

diagram 5.3.

NOTE: The boiler electrical supply cable must not be

routed along the back of the appliance.

The cable must be kept well clear of hot surfaces.

When fitting the back boiler unit do not trap the cable.

5.2 Control Thermostat Phial

Unwind the capillary avoid kinking, make sure that the

capillary is positioned so that it passes through the cut out in

the side of the control box, see diagram 5.7. Route the

capillary well clear of any part of the back boiler which

becomes hot. Use the capillary clips, supplied. Secure the

capillary and push the phial into the pocket, secure the phial

with the retaining pin supplied, see diagram 5.4. Again make

sure that the capillary is not touching the casting.

NOTE: When fitting the phial into the phial pocket use the

heat sink compound supplied in the fittings pack.

CABLE CLIPS

ELECTRICAL

SUPPLY

CABLE