Maintenance, 13 trouble-shooting – Glow-worm Clearly Heat Pumps - Standalone Module System User Manual

Page 34

0020096321_00 - 07/10 - Glow-worm

- 32 -

MAINTENANCE

MAINTENANCE

13 Trouble-shooting

13.1 Fault

diagnosis

The following checks should be performed before proceeding

onto specifi c diagnostics:

- Make sure that the electricity supply has not been interrupted

and that the appliance is connected correctly.

- Ensure that the isolating valves are open.

- Check that all external controls are connected correctly.

13.2 Fault

codes

i

The faults described in this chapter should be

carried out by a qualifi ed engineer and if needed by

the After Sales Service.

13.2.1

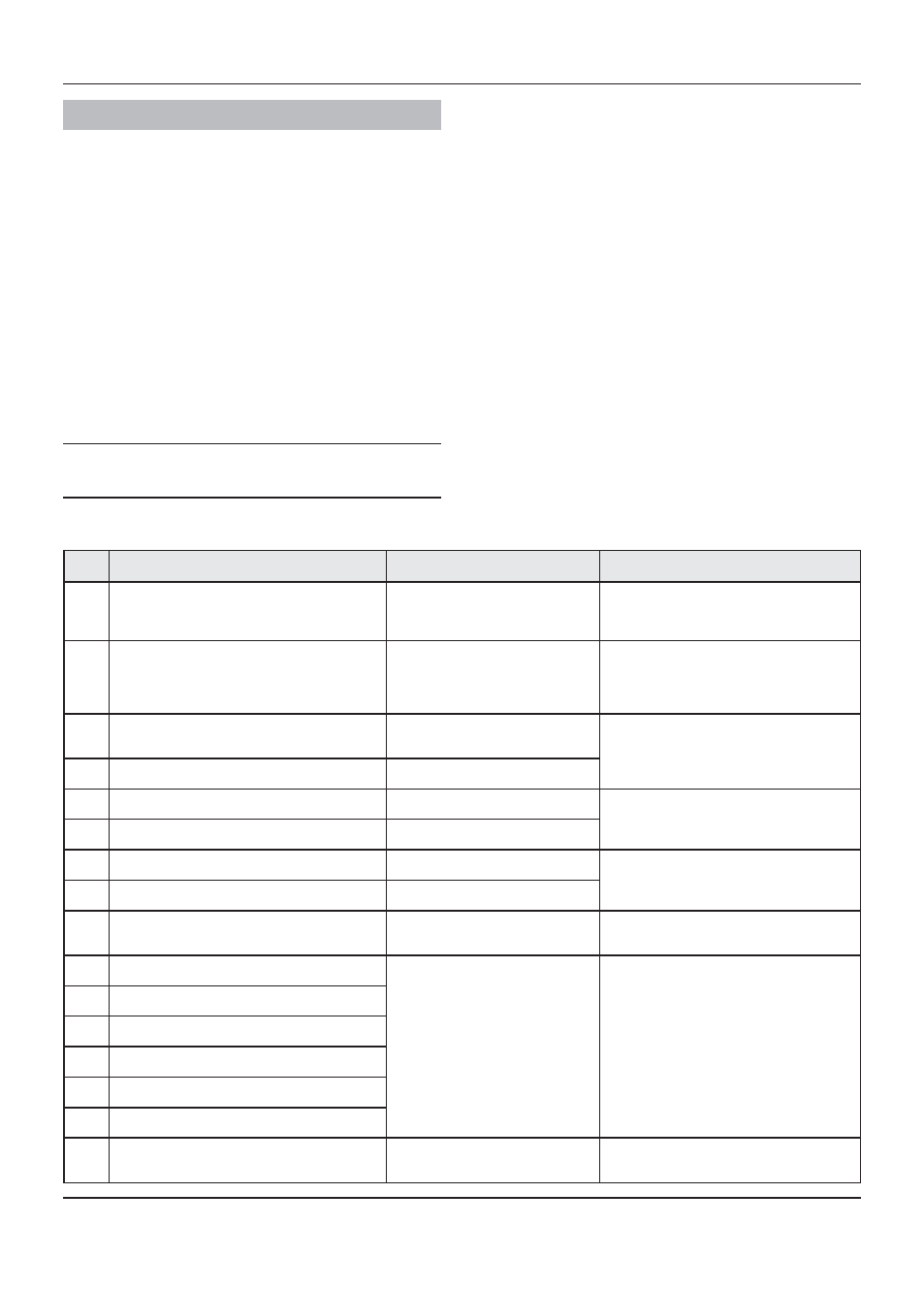

System fault codes

Fault

codes

Description

Cause

Solution

002

Failure in Ebus communication between with the

heat pump

The heat pump is not connected to

the control unit.

The heat pump is off.

Make sure the heat pump is connected to the

control unit. Ensure that there is no interruption

to the electricity network and that the heat

pump is properly connected and turned on.

003

Failure in Ebus communication between with the

hydraulic module

The hydraulic module is not

connected to the control unit.

The hydraulic module is off.

Make sure that the hydraulic module is

connected to the control unit. Ensure that there

is no interruption to the electricity network and

that the hydraulic module is properly connected

and turned on.

010

Heating circuit fl ow temperature sensor failure

(open circuit)

The sensor is defective or not

properly connected to the control unit

management or hydraulic module.

Check the sensor’s connections.

Verify that the position and the operation of the

sensor are correct.

Check the sensor’s resistance.

011

Heating circuit fl ow temperature sensor failure

(short circuit)

The sensor is shorted.

012

Heating circuit fl ow temperature sensor failure low

temperature (open circuit)

The sensor is defective or not properly

connected to the control unit.

Check the sensor’s connections.

Verify that the position and the operation of the

sensor are correct.

Check the sensor’s resistance.

013

Heating circuit fl ow temperature sensor failure low

temperature (short circuit)

The sensor is shorted.

014

Domestic water tank temperature sensor failure

(open circuit)

The sensor is defective or not properly

connected to the control unit.

Check the sensor’s connections.

Verify that the position and the operation of the

sensor are correct.

Check the sensor’s resistance.

015

Domestic water tank temperature sensor failure

(short circuit)

The sensor is shorted.

021

Pressure too low <0.5 bar

There is a leak in the heating circuit.

The venting was not carried out

correctly.

Check that there are no leaks.

Drain the heating circuit. Remove air.

Fill the installation.

030

Failure in communication with the zone 1 wireless

room thermostat.

The room thermostat is too far from

the control unit.

There is a problem with the batteries

in room thermostat.

Check the RF signal quality via the Climapro2

RF installer menu.

Check the location of the thermostat.

Check that the thermostat’s batteries are

installed in their compartment.

Make sure the battery polarity is not reversed.

Make sure the batteries are not dead.

If so, replace them with new batteries

031

Failure in communication with the zone 2 wireless

room thermostat.

032

Failure in communication with the zone 3 wireless

room thermostat.

033

Failure in communication with the zone 4 wireless

room thermostat.

034

Failure in communication with the zone 5 wireless

room thermostat.

035

Failure in communication with the zone 6 wireless

room thermostat.

036

Failure in communication with the wireless

outdoor sensor

The wireless outdoor sensor is too far

from the control unit.

Check the location of the outdoor sensor.

Check that the sensor’s power supply is

correctly provided by a photovoltaic cell.