14 settings, 15 routine cleaning and inspection – Glow-worm 23c User Manual

Page 22

22

2000225000B

9532

PRODUCTS

SAMPLING

POINT

Diagram 15.1

REMEMBER, when replacing a part on this appliance, use only

spare parts that you can be assured conform to the safety and

performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised

by Hepworth Heating.

To ensure the continued efficient and safe operation of the

boiler it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon

the particular installation conditions and usage, but in general

once a year should be enough.

It is the law that any servicing is carried out by a qualified

registered person.

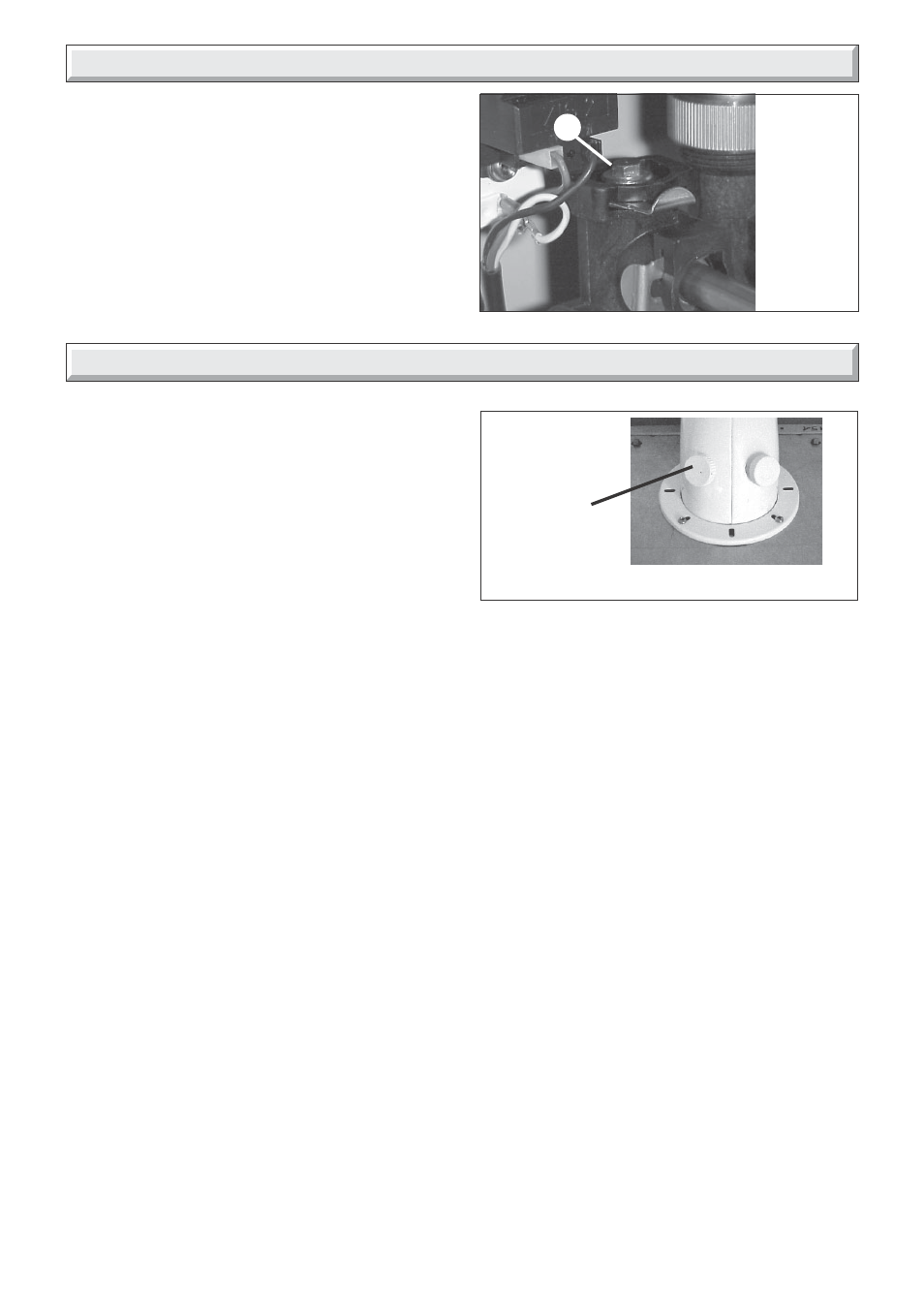

15.1 Products of combustion check

Note: To obtain a products of combustion reading, unscrew the

left hand sampling point cap on the flue elbow, located on top

of boiler, see diagram 15.1.

Connect the analyser tube onto sampling point.

Refer to the combustion product values in Section 1 Technical

Data.

Switch on the electrical supply and gas supply, then operate the

boiler.

On completion of the test switch off the electrical supply and the

gas supply, remove analyser tube and replace sampling point

cap.

15.2 Service Check and Preparation.

• Isolate boiler from the gas and electrical supplies.

• Drain the Domestic hot water circuit and the boiler, refer to

diagram 15.2.

• On completion check all gas-carrying parts for soundness with

leak detection fluid.

• Remove boiler casing as follows:

Diagram 14.1

9975

14 Settings

A

Bypass

The 23c boiler has a built-in bypass. This must be adjusted

according to the requirements of the system, refer to the flow

rate pressure curve (diagram 1.1). The boiler is supplied with

the built-in bypass open a half a turn. It is adjusted by turning the

bypass screw (a), see diagram 14.1. Turn the screw clockwise

to close the bypass. When using thermostatic radiator valves

(TRV’s) on all of the radiators, it is essential that a separate,

adjustable bypass of 15 mm minimum diameter is fitted between

the flow and return of the heating circuit, see diagram 8.1. Any

bypass must be fitted before system controls.

15 Routine Cleaning and Inspection

15.3 Front panel

• Unscrew and remove the two retaining screws from the bottom

of the front panel.

• Remove front panel by pulling forward and lifting up.

15.4 Control panel

• Lower forwards to gain access to lower part of boiler.

15.5 Sealed chamber cover

• Unclip the two toggle clips holding the sealed chamber cover,

see diagram. 15.3.

• Lift cover up and off pins on the top of the boiler.