8 piping system installation – Glow-worm 23c User Manual

Page 14

14

2000225000B

20mm

MIN.

165mm

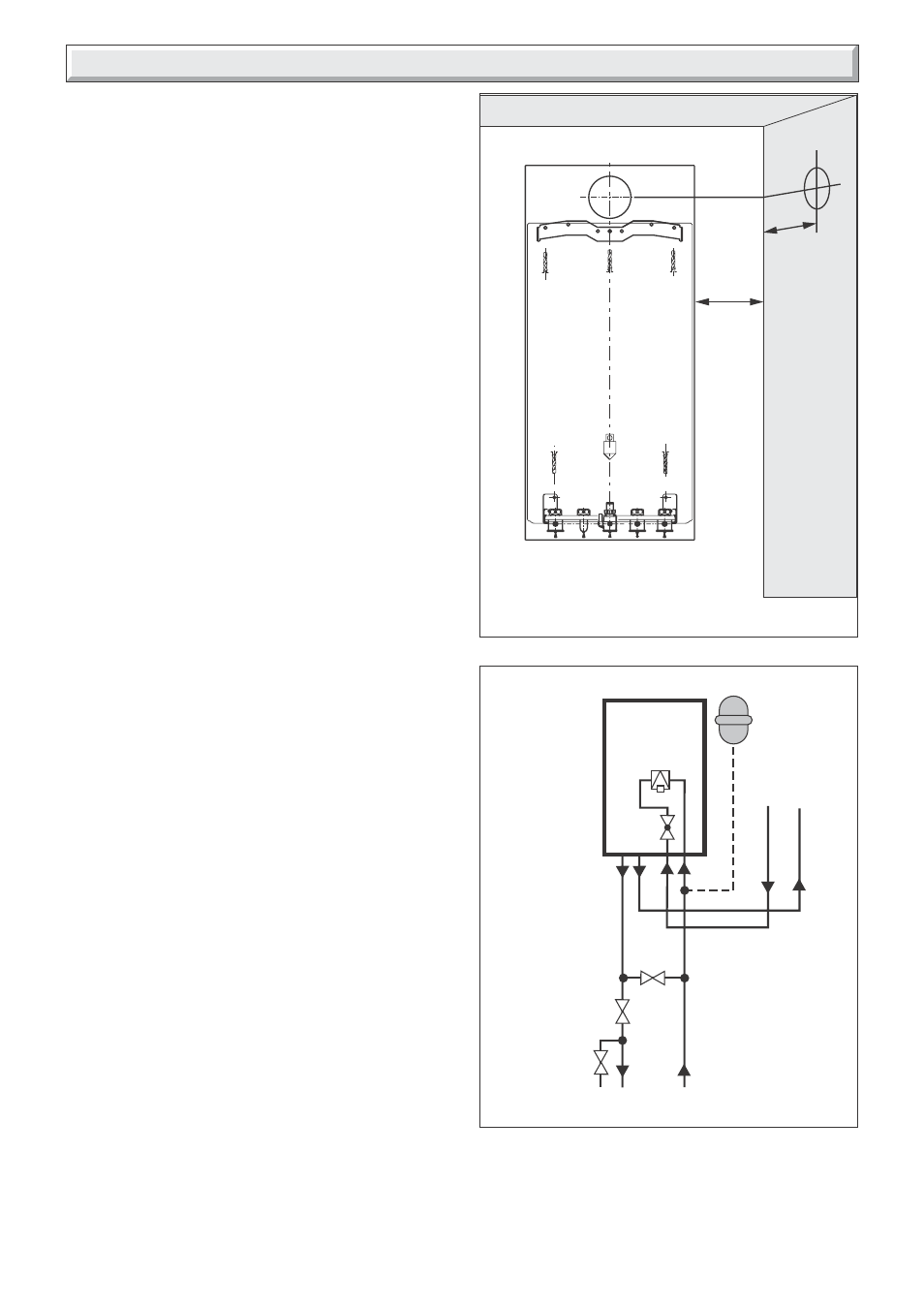

8.1 Fixing jig, see diagram 7.1

• Remove the contents of the fixing jig pack.

• Secure the left and right hand support brackets to the isolating

valve plate with the securing screws (2 OFF) supplied.

• Connect the five copper connections and sealing washers to

the isolating valves.

1 Heating system connections - Pipe diam. 22mm

2 Hot water system connections - Pipe diam. 15mm

3 Gas connection - Pipe diam. 15mm

8.2 Wall template

• Remove the wall template, follow the instructions given on the

wall template.

• Note: It is important the hanging bracket and service cock

bracket are fitted to a flat and true wall area for correct alignment

with the boiler. If this cannot be achieved it is acceptable to pack

out the service cock bracket to obtain the correct alignment.

• Position the wall template, see diagram 8.1.

• Mark the position of the holes for the hanging bracket and jig.

• Drill, plug and fix the hanging bracket to the wall using suitable

screws (not supplied).

• Check that the hanging bracket is level.

• Drill plug and fix the fixing jig to the wall.

• For horizontal flue system, mark the position for the flue hole

as follows:

8.3 Flue to rear of boiler

• Mark correct position of hole from template.

8.4 Flue to side of boiler

• Mark the horizontal centre line for the hole on the rear wall.

Extend the horizontal centre line to the side wall and mark the

vertical centre line of flue hole as shown in diagram 8.1.

8.5 Cutting the flue hole

• Making allowance for the slope of the flue, cut hole in external

wall, preferably using a core drill. For installations with internal

and external access use a 105 mm diameter core drill.

For installations with internal access only use a 125 mm

diameter core drill.

Important

When cutting the flue hole and when extending the flue centre

line to a side wall, remember that the flue system must have a

fall of about 35 mm per metre of flue DOWNWARD towards the

terminal. There must NEVER be a downward incline towards

the boiler.

8.6 Water connection

Connect the system pipework to the copper connections on the

fixing jig observing the correct flow and return format as shown

in diagram 8.2. Do not subject the isolating valves to heat.

8.7 Gas connection

• The supply from the governed gas meter must be of adequate

size to provide a constant inlet working pressure of 20 mbar (8

in w.g.).

8 Piping System Installation

10038

Diagram 8.1

Diagram 8.2

9898

Control

valve

Flow

Drain

point

Bypass

valve

Domestic

water

Heating

circuit

Return

Additional

expansion

vessel

(if required)

Hot water out

Cold supply in

Boiler

Filling device

Refer to

Section 14

*

*