Assemble/set ramps – EZ-ACCESS TITA MODULAR ACCESS SYSTEM User Manual

Page 9

– 9 –

2. ASSEMBLE/SET RAMPS:

2.1

Begin setting ramps with the uppermost ramps in the system.

2.2

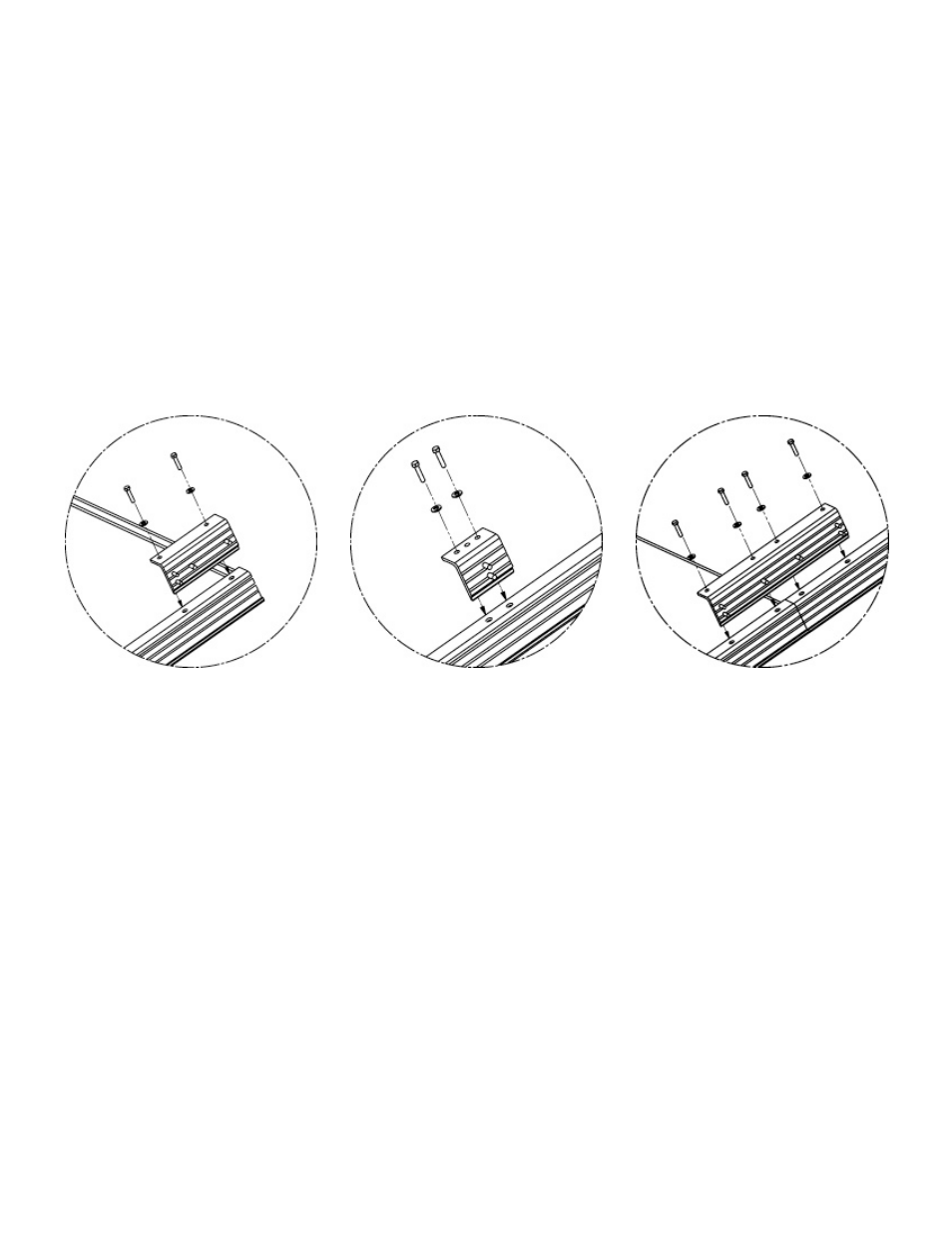

There are three different bracket types that are used to assemble ramp sections (see FIG. 13a,

FIG. 13b and FIG. 13c). All three bracket types are fit into the side rail of the ramp section and

are best installed with the ramp section placed upside down using the 5/16-18” x 1.5” hex bolts

and washers. Note: Take care that the narrow edge of the bracket engages the trough formed in

the ramp section side rail as well as aligns with the threaded inserts preinstalled in the ramp

section side rails. Use ½” wrench or socket to secure fasteners.

2.2.1 End support assembly bracket (FIG. 13a): These brackets come in a left and right pair

and attach to the upper and lower end of a ramp run to support the ends of the ramp run

when combined with support legs. These brackets also provide attachment points for the

guardrails.

2.2.2 Guard brackets (FIG. 13b): This pair of brackets provides an attachment point for the

guardrails at the mid-point of a ramp section.

2.2.3 Center support assembly bracket (FIG. 13c): This pair of brackets joins ramp sections

together and is required where ramp sections meet in a ramp run. They support the ramp

at this point when combined with support legs and provide attachment points for the

guardrails.

FIG. 13a

FIG. 13b

FIG. 13c

2.3

If using a single ramp as the first upper section:

2.3.1 Lay the ramp section upside down.

2.3.2 Install end support assembly brackets (FIG. 13a) at both ends of the ramp section. This

will require two pairs of end support brackets. Note: Make sure that the two larger

diameter studs protruding from the brackets are positioned toward the outer end of the

ramp section.

2.3.3 Install one pair of guard brackets (FIG. 13b) at mid-point of ramp section in similar

manner.

2.4

If using two or more ramp sections for uppermost ramp run:

2.4.1 Lay ramp section end-to-end upside down on a level surface (a level surface will make

sections easier to connect).

2.4.2 Install one pair of center support brackets (FIG. 13c) at each junction of two ramp

sections. Note: It is critical that the center support bracket be positioned equally with

respect to threaded inserts in the ramp sections to avoid problems aligning the guards

and handrails later. This may require measuring. There is a centering mark on the

support bracket to assist with this process.

2.4.3 Install end support assembly brackets (FIG. 13a) at both ends of the ramp run (this will

require two pairs of end support brackets). Note: Make sure that the two larger diameter

studs protruding from the brackets are positioned toward the outer end of the ramp

section.

2.4.4 Install one pair of guard brackets (FIG. 13b) at the mid-point of each ramp section

making up the run.

2.5

If using as a turn or turn-back: