E-Tech EH series User Manual

Page 7

13

12

2.2 Temperature of pumped fl uids

The pumped liquids must remain within certain

temperature limits:

• with EPDM seals: -15° to +110°C

• with VITON seals: -15° to +90°C

• with NBR seals: -15° to +80°C

3. INSTALLATION AND PREPARATION

3.1 Conditions of use

The horizontal electric pumps are multistage pumps

operating with clockwise rotation looking at the electric

pump from the motor fan.

• Pump not self-priming.

• Maximum density of the pumped liquid: 1.1 kg / dm³.

• Allowed voltage variation: ± 5% (single-phase voltage

220÷240V 50Hz, three-phase 380÷415V / 220÷240V

50Hz).

• Degree of protection: IP55.

• Sound pressure level lower than 70 dB (A).

• Dimensions and overall dimensions (See technical

catalog).

• Maximum ambient temperature: +40°C.

3.2 Minimum suction pressure

Check the characteristic curves of electric pumps to

evaluate the NPSH factor and avoid cavitation problems

(case in fi gure 1.B on page 4).

3.3 Maximum suction pressure

It is important to maintain the sum of input and output

pressure; this latter, with closed opening, shall always

be lower than the allowed maximum operating pressure

for the electric pump. However, the maximum operating

pressure shall never exceed 10bar (case in Figure 1.A

on page 4).

3.4 Minimum

nominal

fl ow rate

The operation of the electric pump at a lower level

of nominal minimum allowed fl ow rate may result in

excessive overheating, which may damage the electric

pump.

m

The electric pump must never be operated with

the discharge valve closed.

4. ELECTRICAL CONNECTIONS

c

Before beginning to work on the electrical pump,

make sure that you have disconnected the

electricity from the power supply mains and that

it cannot be accidentally reconnected.

The installation of the electrical pump can involve a

certain amount of complexity. For this reason, it must be

performed by competent and authorized installers.

Legend fi gure 1 (see also p. 4):

1. Filter (maximum passage section of 1 mm)

2. Valve-fi lter (maximum passage section of 1 mm)

3. Gate valve

4. Manometer

5. Check Valve

6. Positive slope

7. Pipe anchoring elements

8. Storage container

There may be two important application cases:

• Case outlined in fi gure 1.A (see p. 4). System with pump

under head (positive head), be it a tank as shown in the

fi gure or the civil water supply network, the system must

provide protection in case of lack of water.

• Case outlined in fi gure 1.B (see p. 4): Plant with suction

pump.

4.1 Mounting

Install the pump in an accessible place, protected against

frost and as close as possible to the water collection

point.

The electric pump must be fi rmly attached to the base by

means of bolts.

Allow enough space around the electric pump to allow

use and maintenance operations, as well as any possible

collection of hazardous liquids or liquids that need to be

drained at a temperature above 60 °C. In any case, make

sure that there is a clearance of at least 100 mm from the

cooling fan.

To avoid unnecessary stress to the pump body install

support brackets (see Figure 1, note 7 on page 4) to

support the inlet and outlet pipe.

To avoid air pockets harmful to the electric pump

operation, provide for an inclination of the inlet pipes of at

least 2% (see Figure 1, note 6 on page 4.)

Protect the pump from any water hammer through a check

valve placed in the delivery pipe. Install a shutoff valve

upstream and downstream of the pump so as to allow its

isolation in case of maintenance and disassembly.

The diameter of inlet pipes should never be less than the

diameter of the inlet opening.

For the diameter of the connection piping refer to the

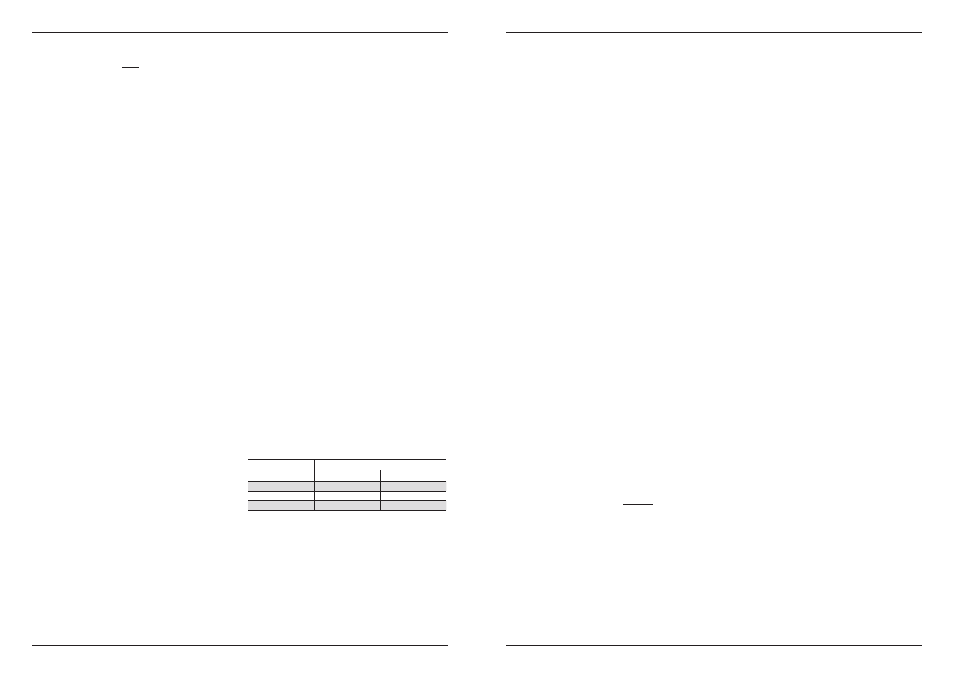

following table:

Pump type

DN threaded sleeves

Suction

Delivery

3

1" ¼

1"

5

1" ¼

1"

9

1" ½

1" ¼

4.2 Electrical

connections

c

Before beginning to work on the electrical pump,

make sure that you have disconnected the

electricity from the power supply mains and that

it cannot be accidentally reconnected.

Connections must only be performed by an authorized

electrician in compliance with law in force.

c

Verify that the data on the name plate match

the nominal values for the power line. Make

the connection after verifying the existence of

a working grounding circuit. It is the installer’s

responsibility to perform the connection in

compliance with regulations in force in the

country of installation.

Connect the electric pump by means of an external

network switch having a minimum distance between the

contacts of at least 3 mm on all poles.

Connect the wires to the motor according to the diagram

shown inside the terminal cover.

• For single-phase versions see Figure 3.A on page 5.

• For three-phase versions see Figure 3.B on page 5.

c

Use cable complying with the regulations,

equipped with ground wire (3 conductors for

single-phase versions and 4 conductors for

three phase versions)

c

Avoid any way contact between the electric

cables and the pipes or other parts of the pump;

carefully insulate the cables from moisture.

The single-phase versions are accompanied by internal

capacitor to the output variable.

For all single-phase versions, the engine is protected

against overloads by means of a thermal device (overload

cut-out) inserted into the winding.

The three-phase versions require external protection

(quick disconnect magnetic overload cut-out) with a

tripping time set to:

• Less than 10 seconds with 5 times I

N

• Less than 10 minutes with 1.5 times I

N

I

N

= maximum current value indicated on the rating plate.

The pump must supplied through a residual current

device (RCD) with a rated residual operating current

≤30mA.

4.3 Checking the direction of rotation

After connecting the power supply, the direction of

rotation can be inverted in the 3-phase versions; in this

case, performance will be signifi cantly lower than the

nominal values. To verify a correct connection, proceed

as follows:

1) Start the pump, check that the direction of rotation is

as indicated by the arrow. Warning! If this operation is

made under dry conditions, it shall not last more than

a few seconds.

2) To correct the rotation is suffi cient to invert the two

phases.

c

Do not fail to connect the grounding.

5. COMMISSIONING

CAUTION: The pump should NOT be started without

having been fi lled fi rst. Its dry use may irreparably

damage the mechanical seal.

5.1 Filling

5.1.1 Electric pump being charged (see fi gure

1.A and fi gure 2.A on page 4 and 5)

1. Close the gate valves on the delivery side of the

electric pump so as not to let the fl uid that you are

using for fi lling the electric pump circulate in the

circuit.

2. Remove the fi lling cap (see Figure 2.A on page 5).

3. Open the gate valve placed on the suction side of the

pump to drain the fl uid present in the pump. Make

sure that the difference in level between the pump

and the head is such as to ensure a complete fi lling of

the pump.

4. When there is a homogenous fl ow from the fi lling

hole, place the fi lling cap carefully back to its position.

5. Start the pump and check, only on three-phase

versions, that the direction of rotation is as indicated

by the arrow. To correct the direction of rotation is

suffi cient to invert the two phases.

6. Slowly open the valve gate on the delivery side till its

stroke end.

m

Pay particular attention to point 3 - when the

pump is fi lled with hot liquids or hazardous

liquids, fl uid leaking from the drain cap could hit

more people; make sure to be in a safe position

during this operation. In this case, close the

gate valve after the release of a constant fl ow

of liquid from the cap before closing it in order to

avoid contact with the liquid.

m

Depending on the temperature of the pumped

liquid, the electric pump surfaces can reach high

temperatures. If deemed necessary, provide for

guards to prevent accidental contact.

5.1.2

Pump during suction operations (see

fi gure 1.B 2.A fi gures and on page 4 and

5)

1. Close the gate valves on the delivery side of the

electric pump so as not to let the fl uid that you are

using for fi lling the electric pump circulate in the circuit

and open the gate valve on the suction side.

2. Remove the fi lling cap (see Figure 2.A on page 5).

3. Fill the pump as outlined in fi gure 2.A until the fl uid

comes out from the fi lling hole.

4. Close the fi lling cap carefully.

5. Start the electric pump and check, only in three-phase

versions, that the direction of rotation is as indicated

by the arrow. To correct the direction of rotation is

suffi cient to invert the two phases.

7. Slowly open the gate valve on the delivery side till its

stoke end.

m

Depending on the temperature of the pumped

liquid, the electric pump surfaces can reach high

temperatures. If deemed necessary, provide for

guards to prevent accidental contact.