E-Tech EH series User Manual

Page 6

11

10

●

L’elettropompa non funziona all’avviamento

●

La protezione termica del motoavviatore interviene al momento dell’accensione

●

La protezione termica del motoavviatore interviene occasionalmente

●

La portata risulta ridotta o non costante

●

L’elettropompa gira ma non eroga acqua

●

L’elettropompa vibra

Possibili cause imputabili alla elettropompa

Soluzione

█

Mancanza di tensione elettrica

Collegare la tensione elettrica

█

Fusibili bruciati

Cambiare i fusibili

█

Protezione termica intervenuta

Ripristinare la protezione termica

█

Guasto nei contatti del termico del motoavviatore

Sostituire i contatti del motoavviatore

█

Collegamento dei cavi difettoso

Fissare o sostituire i cavi

█

Blocco meccanico dell’elettropompa

Eliminare

il

blocco

meccanico

dell’elettropompa

██

Taratura del relè termico troppo bassa

Tarare correttamente il motoavviatore

█

Bassa tensione durante i picchi

Controllare l’alimentazione elettrica

█

Pressione in aspirazione troppo bassa (cavitazione)

Controllare l’NPSH dell’elettropompa

██

Collettore di aspirazione / elettropompa parzialmente

ostruiti dalle impurità

Pulire l’elettropompa o il collettore di

aspirazione

█

L’elettropompa aspira aria

Controllare le condizioni di aspirazione

█

Valvola di fondo o di ritegno bloccate in posizione chiusa

Riparare la valvola di fondo o di ritegno

█

Perdita nel collettore di aspirazione

Riparare il collettore di aspirazione

█

Presenza di aria nel collettore di aspirazione o

nell’elettropompa

Controllare le condizioni di aspirazione

█

Il motore dell’elettropompa ruota nel senso errato

Cambiare il senso di rotazione del motore

█

Ancoraggio sul plinto difettoso

Verifi care e avvitare completamente i dadi dei

bulloni delle viti prigioniere

█

Corpi estranei ostruiscono l’elettropompa

Far smontare l’elettropompa e pulirla

█

Rotazione "dura" dell’elettropompa

Verifi care che l’elettropompa giri liberamente

senza opposizioni anormali

█

Collegamento elettrico difettoso

Verifi care i collegamenti dell’elettropompa

EN

SAFETY RULES

NOTE: Before installing and using the electrical

pump, carefully read the instructions provided below.

This manual contains fundamental instructions that

must be followed during installation, operation and

maintenance. This manual must be consulted by the

person in charge of assembly and by all qualifi ed

personnel who will follow its operation, as designated by

the installation manager. In addition, this manual must

always be available at the location where the electrical

pump is used.

Identifi cation of the coded instructions contained in

this manual

m

The safety rules in this manual whose lack of

observance can cause physical damage are

marked with the general danger symbol.

Risks deriving from the failure to observe safety rules

The failure to respect the safety rules can cause physical

and material damage in addition to possibly polluting the

environment. The failure to observe safety rules can void

the warranty.

To cite a few examples, the failure to respect safety rules

can cause:

• the failure of the installation or the electrical pump’s

principal functions,

• compromised maintenance operations,

• mechanical or electrical damage to people

General Information

This electrical pump has been manufactured using the

most recent and advanced techniques, in full respect for

laws in force, and has been subjected to strict quality

control.

This manual will help you understand its operation and will

help you become familiar with its possible applications.

The operation manual contains important

recommendations for the correct and economical

operation of the electric pump. It is necessary to respect

these recommendations in order to guarantee its

reliability and

longevity, as well as to avoid the risk of accident deriving

from improper use.

The electrical pump must never be used outside the

limitations described in the technical specifi cations. It is

necessary to respect the instructions regarding nature,

density, temperature, fl ow rate and pressure of the

pumped liquid, speed and direction of rotation and power

of motor as well as all other instructions contained in this

manual or in the documentation attached to the contract.

The name plate indicates the model, the principal service

specifi cations and the serial number. It is important to

provide this information when requesting assistance or

support and to request replacement parts.

The manufacturer declines all responsibility in the case

of accident or damage caused by negligence, improper

use of the electrical pump or the failure to observe

the instructions provided in this manual or use under

conditions other than those stated in the name plate data.

m

Appliance is not to be used by children or

persons with reduced physical, sensory or

mental capabilities, or lack of experience and

knownledge, unless they have been given

supervision or instruction.

m

Children being supervised not to play with

appliance.

1. PRELIMINARY INSPECTION

1.1 Delivery and Packing

The electric pumps are supplied in their original package,

where they shall remain until installation.

The electric pump should not be exposed to unnecessary

shocks and collisions.

1.2 Storage and handling

Storage temperature:

From -20°C to +60°C

The electric pump should not be exposed to sunlight.

During standstill, the electric pump is to be protected

against frost and weathering. During handling, the

electric pump can be supported as shown in Figure 2.C

on page 5.

Extract the electric pump from the package and verify its

integrity. Also, verify that the rating plate data correspond

to those required. In case of any malfunction, contact

your supplier immediately, indicating the type of defects.

m

If you are unsure about the safety of the electric

pump, do not use it.

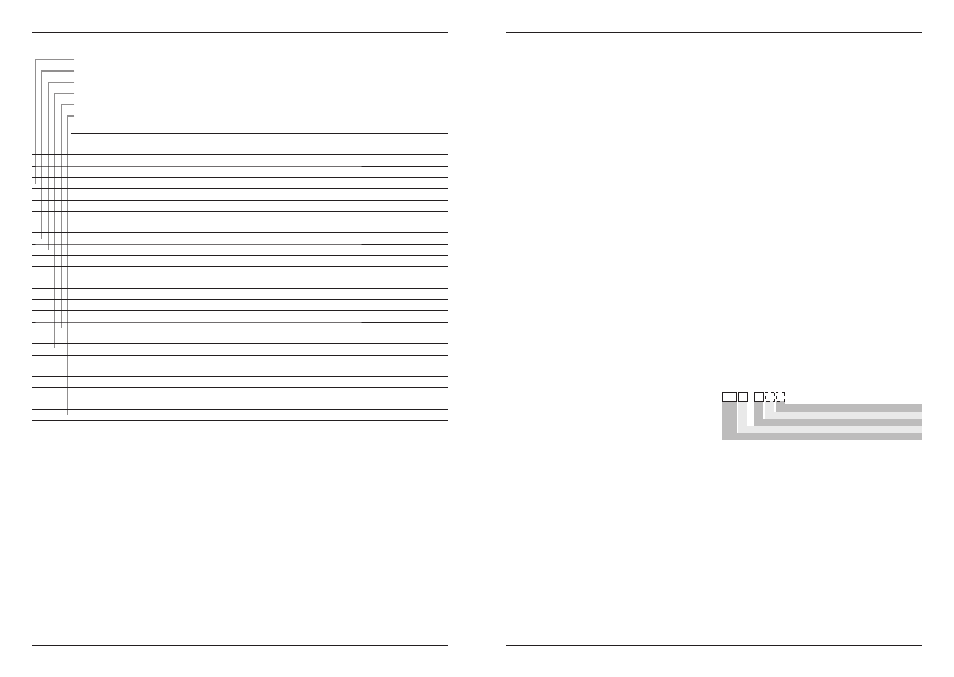

ELECTRICAL PUMP IDENTIFICATION CODE

2. APPLICATIONS

The horizontal multistage centrifugal electric pumps

are suitable for a wide range of applications. From

agricultural use to the civilian and industrial ones, such

as for example: water supply for private dwelling units,

water tanks, watering, small irrigation, pressurization, air

conditioning, etc...

2.1 Liquids

Pumped

Clean, non-aggressive liquids compatible with the

materials used to construct the pump, without solid

particles or fi bres.

Any sand in the water must not exceed 50 g/m³. A higher

concentration of sand will reduce the life of the electrical

pump and increase the risk of its locking up.

60 Hz (without this digit it is a 50 Hz pump)

Blank for single-phase version. (T) for three-phase version

Number of stages

Rated flow rate m³/h

Electrical pump model

EH 3

6

/

7

T