Dillon Precision Super 1050 User Manual

Page 8

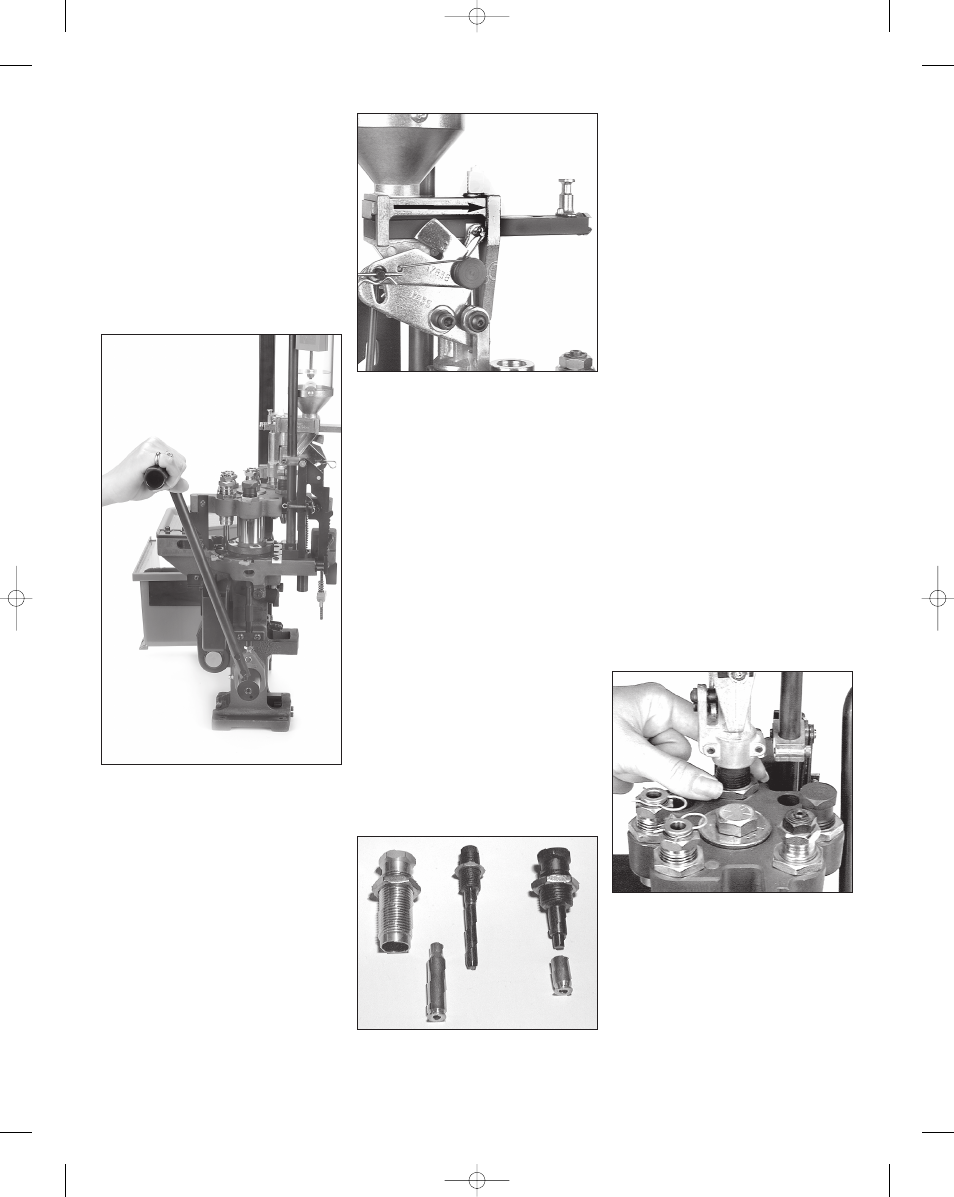

Step 5: Cycling the Machine

At this point your assembly should be

complete. Gently pull the operating han-

dle towards you, make a full stroke to

the bottom and up again. The shellplate

should be indexing and the primer slide

(#20318*) should function. The casefeed

plunger (#13073*) should travel forward

to the shellplate. Make sure that you

repeat this several times to gain an

understanding of the various functions of

the machine before you start reloading.

Fig. 13

Now plug in the casefeed motor and

activate the switch. The casefeed plate

should turn smoothly within the case-

feed bowl.

Assuming that all is well, proceed

with components.

Loading Components

Your Super 1050 is equipped with a

cartridge activated powder measure that

will dispense powder only when a car-

tridge is in Station 5.

It is important to understand that the

adjustable powder bar should reach the

end of its travel at the same time that

the handle reaches the bottom of its

stroke against the frame stop. Fig. 14

To achieve this adjustment, the die

body must be screwed up or down as

needed.

The powder die has already been

adjusted at the factory. An empty case

must be placed in the shellplate at

Station 5 in order to check this adjust-

ment. Note that the case used to adjust

the powder measure die must already be

sized.

NOTE: If you are adjusting for a

straight wall case, start your powder die

adjustment with the die obviously too

high and work down. This will avoid

over belling the case.

If you are adjusting a case with a

shoulder, such as a .223, do not turn the

die down too far or the shoulder will

buckle.

Use a reloading manual to determine

how much powder you need for a par-

ticular load and an accurate powder

scale to determine the weight. Caution:

While you do not have to use a Dillon

Precision powder scale, you should use

a scale of equal quality. Do not use

scales with plastic frames or “razor

blade” pivots. Quality scales have jew-

eled pivot points. Razor blade pivots

can dig into the frame of the scale and

give dangerously inaccurate readings.

Powder Measure Adjustments

In Station 5 we adjust the powder

measure. It works like this: screw the

powder die into the toolhead and insert

the pistol powder funnel expander or a

rifle powder funnel with the grooved end

toward the top of the powder die. Fig.

15 The funnel should move freely in the

die, leaving a loose fit between the top

of the die and the powder measure col-

lar. This will enable you to adjust the die

to give you a bell on the mouth of your

pistol cases making it easier to start the

bullet.

On rifle cases, the die should be

adjusted so that the powder funnel will

contact the mouth of the case and then

fully actuate the powder bar. These

adjustments are accomplished with a

sized case in the shellplate and alter-

nately raising and lowing the operating

handle while adjusting the powder die.

When properly adjusted, the powder

bar will be moved to the end of its travel

by the cartridge case Fig. 14.

When you have determined that your

adjustments are correct, tighten the lock

ring (#14067).

Fig. 16

Powder Bar Return Rod Assembly

The purpose of the powder bar return

rod is to return the powder bar to its

closed position.

Fig. 13 - Cycle the handle several times to

observe the various functions.

Fig. 14 - This photo shows the powder bar at

the end of its travel.

Fig. 15 - Note the difference between the

rifle expander (center) and the pistol

expander (right).

Fig. 16 - Be sure to tighten the lock ring

when adjustments are completed.

8

Super 1050, May 2007 5/21/07 12:00 PM Page 8