Dillon Precision Super 1050 User Manual

Page 22

22

10999

11061

11008

10997

10994

11008

11008

11062

13685

11010

13365

11063

11009

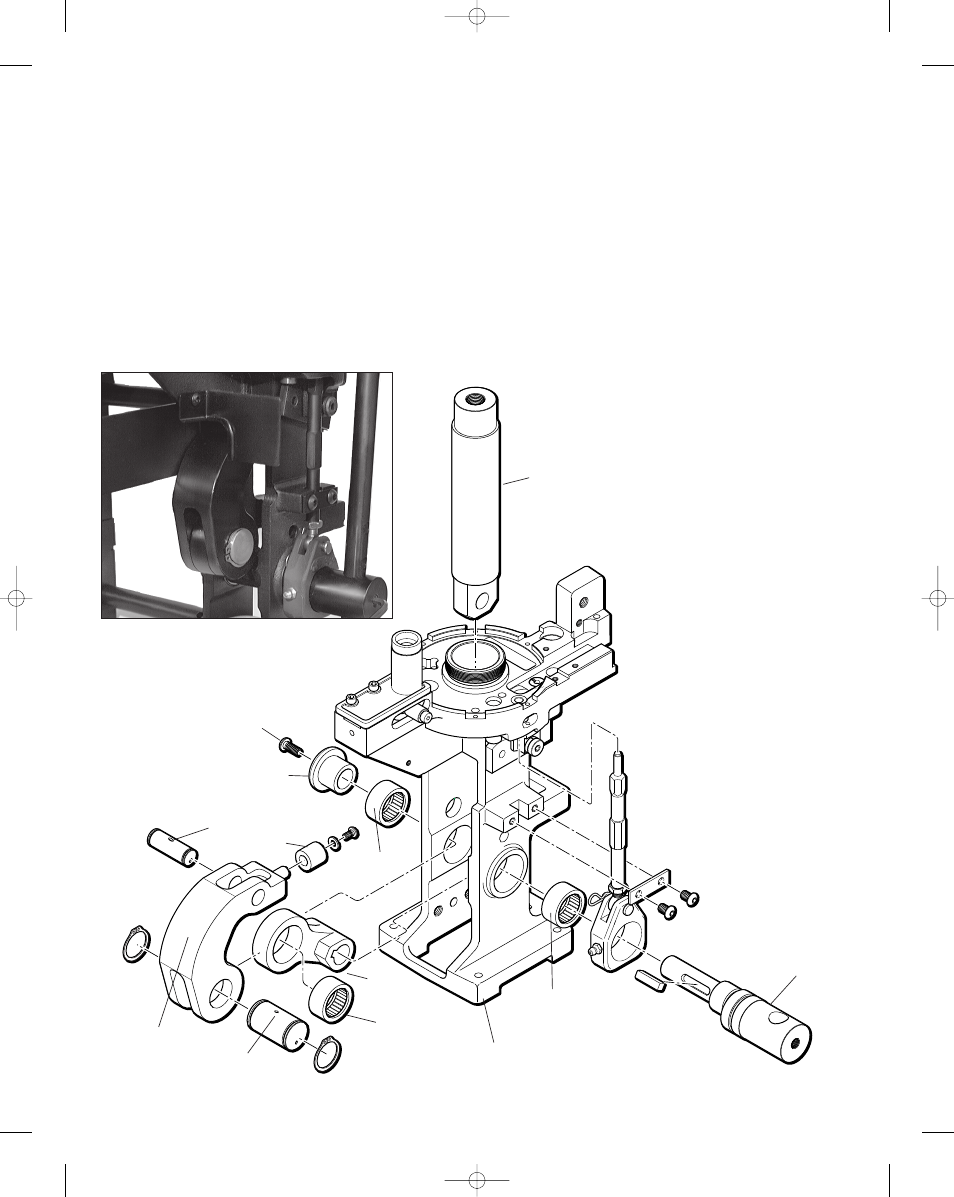

Lube Points for the Super 1050

Crank Assembly

With the handle in the rest position,

on the left side of the machine, use a

grease syringe to lube the bearing pin

(#11009) located in the link arm

(#11063). Then, cycle the handle down

to the bottom stop.

Again, using the grease syringe, lube

the mainshaft pivot pin (#10994) on

the left side of the machine via the

access hole located 1.2" above the car-

rier cap (#11010).

Use 30 weight motor oil on the main-

shaft (#10999).

Towards the back of the machine,

lube the indexing lever cam surface

(#11064) and index lever shoulder

bolt (#13276).

When it is time to lube the roller bear-

ings (#11008) in the frame and crank-

shaft, first remove the swage rod assem-

bly, swage connecting rod, and operating

handle. On the left side of the machine,

use a 5/32" Allen wrench to remove the

screw (#13685). Slide the carrier cap

(#11010) out of its bore and lube the

left-hand side roller bearing (#11008)

and carrier cap. Next, slide the crank-

shaft (#11061) out of the frame from the

right side of the machine BUT NO

MORE THAN 3/4". Using a grease

syringe, dispense some grease onto the

right-hand side roller bearing (#11008).

Next, lube the crankshaft surface

(#11061). Then, reinsert the crankshaft

fully into the frame. Reinstall the carrier

cap (#11010). Blue Loctite must be used

on the threads before installation, tight-

en. Finally, reassemble the swage com-

ponent and operating handle back onto

the frame. Lube the swage connecting

rod (#13417) and clevis pin (#13522).

Super 1050, May 2007 5/21/07 12:00 PM Page 22