Super 1050 assembly – Dillon Precision Super 1050 User Manual

Page 6

make whatever adjustments to the dies

you feel necessary.

Reminder: There may be some varia-

tion due to components.

Super 1050 Assembly

Your new Super 1050 has been

assembled at the factory. All of the

adjustments necessary to reload have

already been made, in fact we’ve even

adjusted the dies to reload the caliber

you have chosen. However, before

you can reload you must do some

minor assembly.

Due to variations in components,

check all stations for proper settings

before loading ammunition. It is

absolutely necessary that you read the

following instructions.

If you get stuck on something that you

don’t understand, call (800) 223-4570

for technical assistance.

Step 1: Mounting the Super 1050

Select a clear area on your reloading

bench. Be certain your bench is free

from vibration and is strong enough to

support your Super 1050’s mass and

operating force. If possible, attach your

bench to the wall using screws.

Remove the Super 1050 main frame

from the packaging and place it on

your selected area. The crank extension

(#11061) should be to your right. Bring

the machine to the forward edge of

your bench – be sure to allow clear-

ance for operation of the handle. Mark

the four mounting holes using the

machine as a template. Remove the

machine and drill four 1/4” holes

through the bench. Replace the

machine and bolt securely.

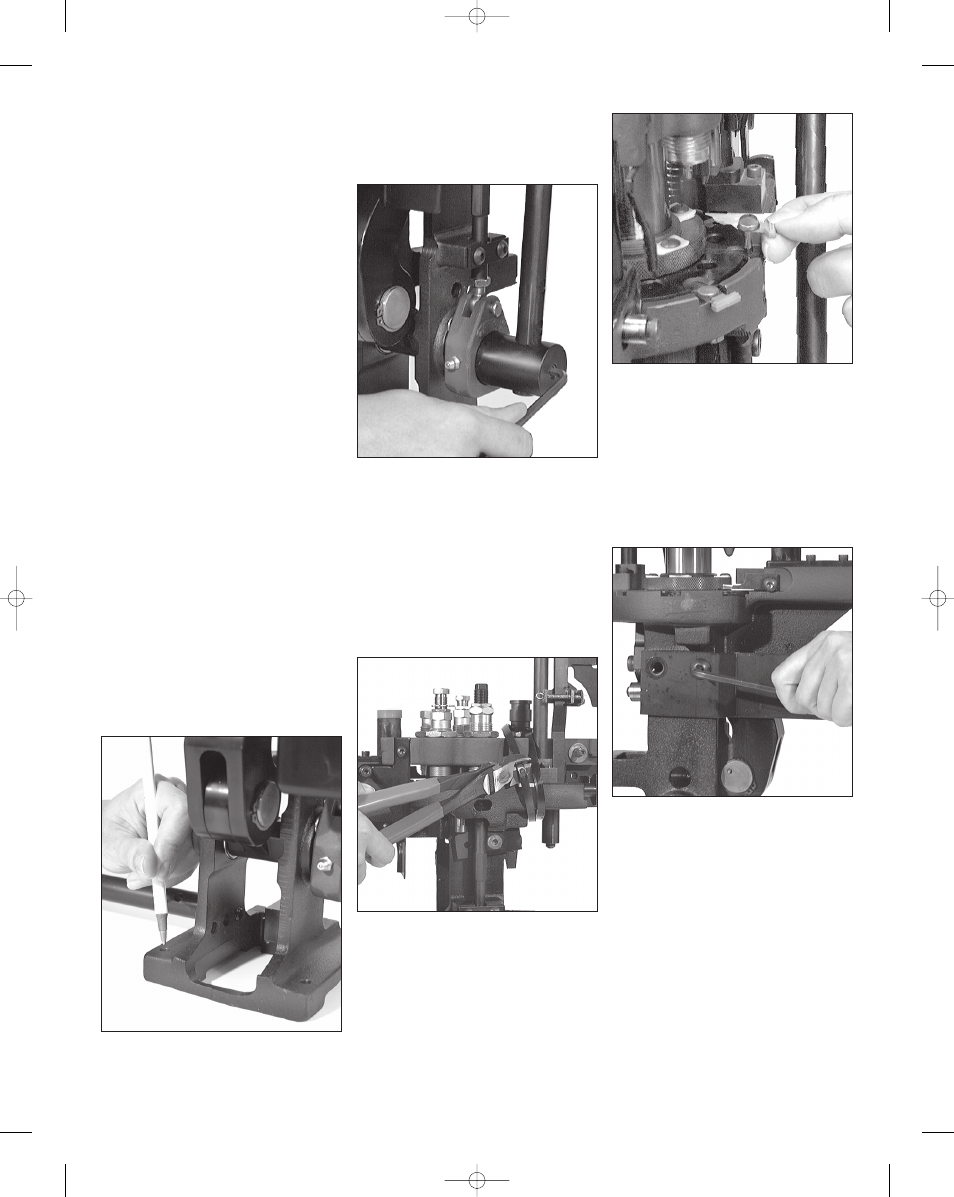

Fig. 1

Install the handle (#17071) as indicat-

ed in the parts schematic. Secure in

place with the handle set screw

(#13432). Fig. 2 You will note that there

are three different positions for mounting

the operating handle. Choose the one

that feels best for you. The longer the

handle, the less force required but the

stroke is longer.

The toolhead (#20420) is held down

on the main frame for shipping by the

use of plastic ties. Remove the ties while

holding the handle Fig 3.

Slowly move the handle up. This will

move the toolhead approximately three

inches to its “up” position. Note: If the

handle is not moving freely, carefully

inspect for shipping damage.

Install the six brass locator buttons

around the shellplate (#12600*).

Fig. 4

Step 2: Installing the Casefeed Assembly

Using the screw provided (#13377)

install the bin bracket (#13238). Fig. 5

Install the bullet bin bracket

(#12144) to the casefeed post (#20641)

using the screw (#13685) as shown in

the schematic on page 30.

Screw the casefeed post studs

(#13271) to the main frame (place

the washer provided on the bottom

post only), tighten securely with an

Allen wrench through the cross hole

provided.

The casefeed mounting post assem-

bly (#20641) is attached to the case-

feed post studs (#13271) by the use of

two post bolts (#13205). Attach the

Fig. 1 - Be sure the machine is to the for-

ward edge of the table or bench when

marking the four holes to be drilled.

Fig. 2 - Note that there are three different

positions for mounting the operating handle.

Fig. 3 - Be sure to hold the operating handle

in place while cutting the plastic ties.

Fig. 4 - Locator button being inserted into

its proper position.

Fig. 5 - See the schematic on page 30 for

more details.

6

Super 1050, May 2007 5/21/07 12:00 PM Page 6