Dillon Precision Super 1050 User Manual

Page 12

Adjustments

Casefeeder

It may be necessary to readjust the

micro-switch for different calibers.

Cases may become lodged between the

micro-switch and the tube wall. The

other extreme is the case failing to put

enough pressure on the micro-switch to

shut off the system causing it to contin-

ue running and over flowing the tube.

Remove the two clutch screws

(#13732), lock washer (#13813) and

upper clutch (#13632) and the case-

feed plate. Place the spacer on the

shoulder of the lower clutch and

reassemble – see the schematic on

page 31 for more details. The casefeed

plate should now be approximately

1/8” above the floor of the casefeed

bowl. Note: Make sure the casefeed

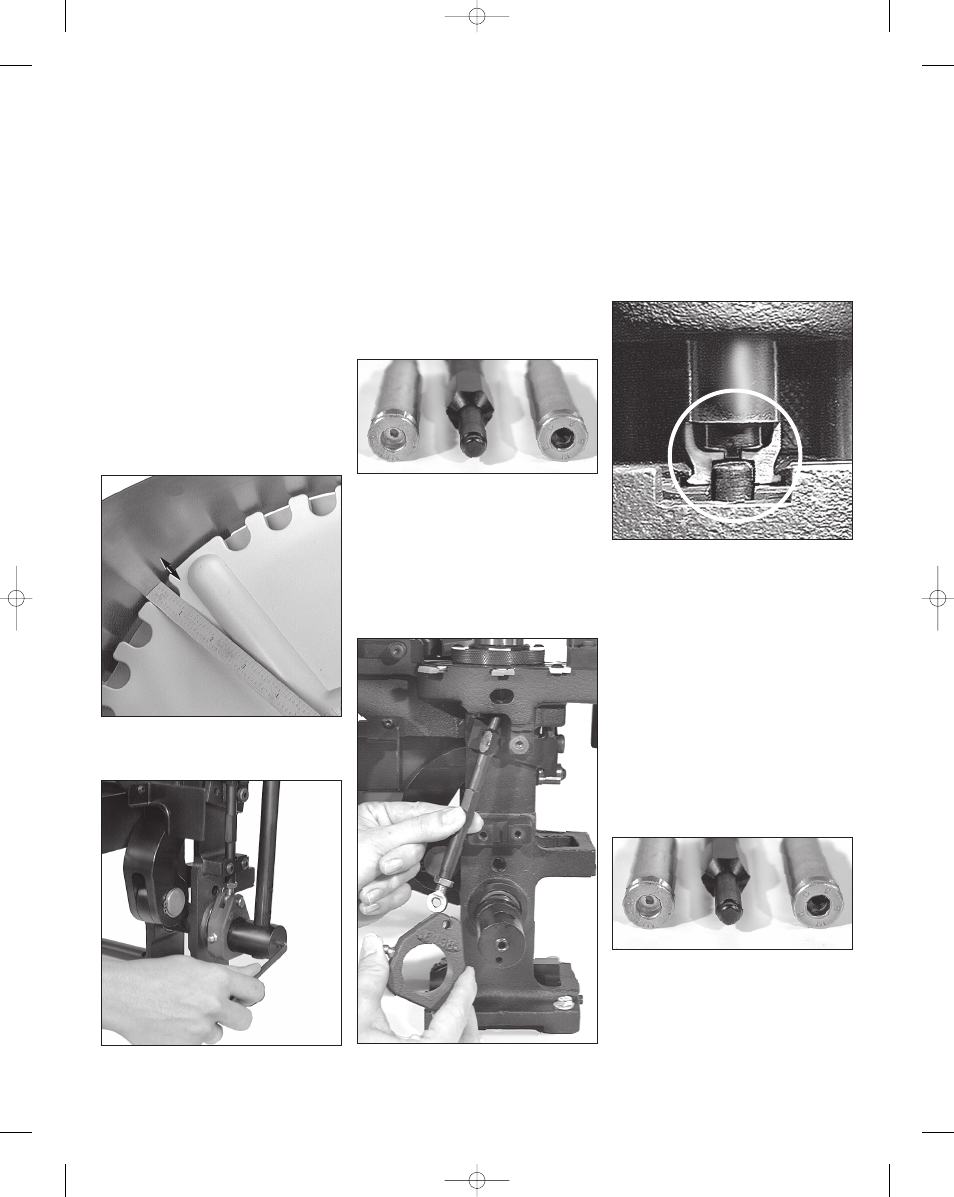

plate is centered in the bowl. Fig. 26

Handle

The operating handle is adjustable to

three different length settings Fig. 27.

Choose the one most comfortable for

your operation. Loosen the set screw

(#13432) then retighten when the handle

is in the most comfortable position.

Swager

Swaging on the Super 1050 is a sim-

ple process and is necessary on all car-

tridge cases as a means of uniforming

the entrance of the primer pocket. Fig.

28 The swage rod (#20314 large or

#20313 - small) is fully adjustable.

Swage Conversion and

Adjustment Conversion – Fig. 29

Begin by removing the swage cover

(#13064). Next remove the hitch pin

(#13840) and slide out the clevis pin

(#13522). Remove the operating handle.

Rotate the swage connecting rod a half

turn and remove it. This will allow you

access to the swager. Pull the swager

down and out of the machine. Fig. 29

Insert the new swager and reassem-

ble.

Swage Adjustments

Use ONLY an unswaged military case

for these adjustments.

With the handle in the down posi-

tion, screw the swage back-up

expander down until it makes contact

with the case bottom and holds it in

place. Fig. 30

With the handle still in the down posi-

tion, turn the swage rod up until it

makes contact with the case bottom.

Raise the handle halfway and rotate

the swage rod a quarter turn. Now, cycle

the handle. Inspect the case and when

you achieve a completed swage of the

primer pocket, tighten the swage lock

nut (#14067).

A properly swaged pocket will show

a rounded edge around the rim. Some

military cases (.223 & .308) start out

with three small dents around the base

Fig. 26 - Make sure the casefeed plate is

centered in the bowl with approximately

1/8” all the way around.

Fig. 29 - See the schematics on page 28 for

more details.

Fig. 28 - Note the difference between the

swaged primer pocket (left) and the

unswaged primer pocket (right).

Fig. 31 - Note the difference between the

swaged primer pocket (left) and the

unswaged primer pocket (right).

Fig. 27 - Note that there are three different

positions for mounting the operating handle.

1/8”

Fig. 30 - A cutaway view of a .45 ACP with

the swage rod and the back-up rod properly

adjusted in the swaging position.

12

Super 1050, May 2007 5/21/07 12:00 PM Page 12