Dillon Precision Super 1050 User Manual

Page 20

Dillon dies whenever possible.

c.) Wrong size or missing locator but-

tons.

2.) Bending or breaking decapping pins:

a.) Wrong shellplate (#12600*).

b.) Slightly bent decapping assembly

or pin.

c.) Berdan primed cases.

d.) Dirt in shellplate pockets.

e.) Handle being moved too rapidly

on the down stroke.

f.) Rocks or other foreign objects in

cases.

Station 3: Primer Pocket Swaging

Problems

1.) Primers smearing or crushing:

a.) Swage back-up rod not down far

enough (#13332 or #13348).

b.) Swage rod not adjusted high

enough (#20314 - large or #20313 -

small).

Station 4: Priming Problems

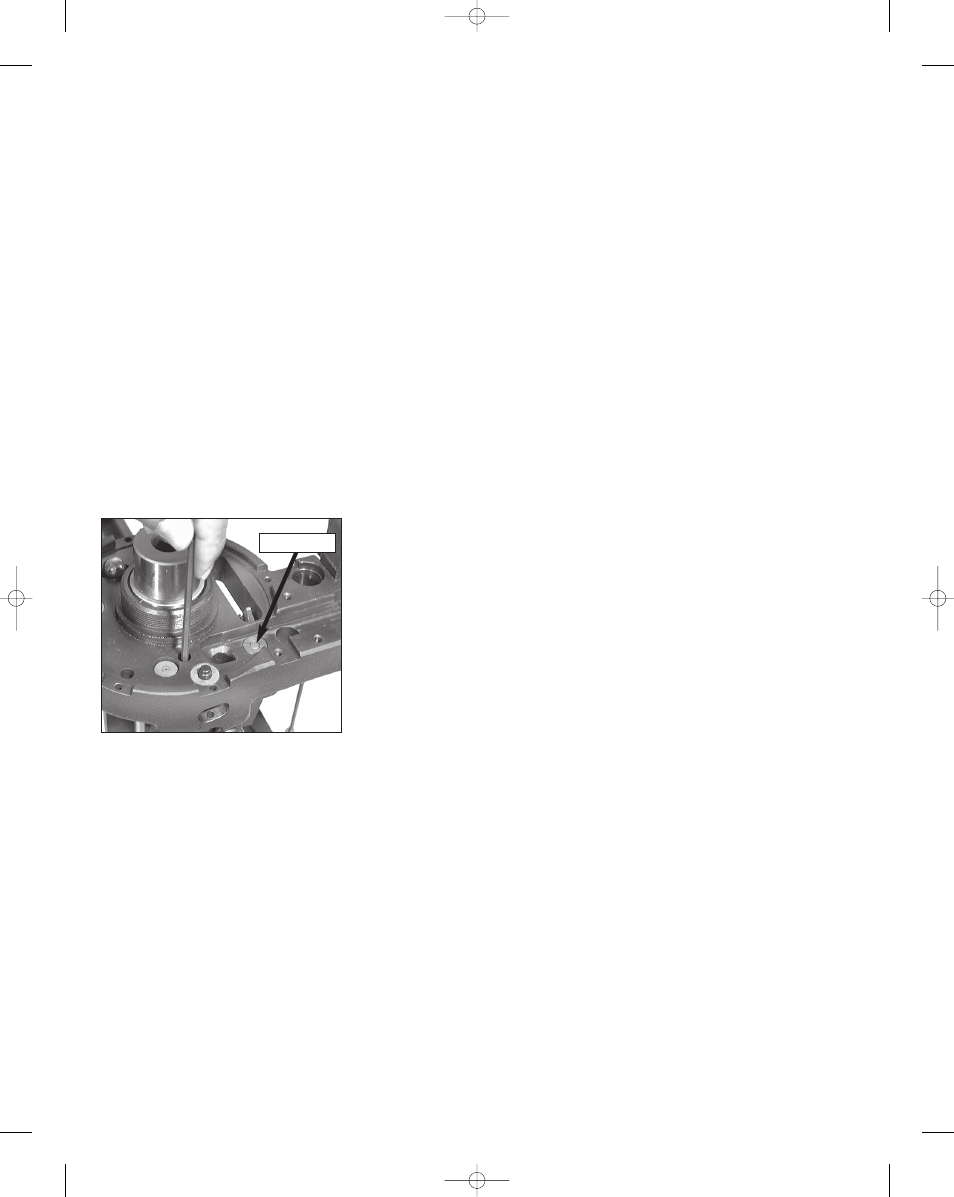

The above photo shows the rocker

arm set screw (#13226) being adjusted.

The Super 1050 comes from the factory

with this set screw properly adjusted, but

over time it can move. When the rocker

arm set screw is out of adjustment, it can

dent primers and/or cause the primer

slide to stick. When properly adjusted,

the primer punch (#12849 large -

#13307 small) will be flush with the

platform surface – see arrow above.

1.) Crushed primers:

a.) Swage rod (#20314 - large or

#20313 - small) not adjusted correctly,

dirty or worn out.

b.) Dirt in the shellplate (#12600*).

c.) Ringed primer. When a spent

primer has been pierced by the decap-

ping pin leaving a ring of metal from the

primer in the pocket.

d.) Primer station retain tab (#12930)

not adjusted correctly.

e.) Worn primer punch (#12849).

f.) The bench that the machine is

mounted on is not rigid enough. This can

be corrected by affixing a board to both

the wall and your bench.

g.) Hot-loaded ammo that has been

fired several times and the base of the

case has been flattened out.

2.) High primers:

a.) Adjust the primer push rod

(#12819).

b.) On .223 cases the swage back-up

rod (#13332) is down too far, slightly

collapsing the primer pocket and not

allowing the primer to seat fully.

c.) Loose shellplate (#12600*).

d.) Erratic handle motion.

e.) Do not remove the rubber piece on

the primer slide.

3.) Smeared primers - see Station 3:

Primer Pocket Swaging - item 1

4.) Locator tab:

a.) When adjusting the priming sta-

tion locator tab, it should be set as

close to the case as possible without

touching it. Be sure the cases in the

shellplate rotate freely past the tab.

Change primer magazine tips every

20,000 rounds. Note: Move the handle

down, bringing the toolhead down.

Move the locator tab in to the case in

the priming station.

Station 5. Powder and Case Mouth

Belling Problems

1.) Crushing cases:

a.) Wrong size or missing locator

buttons.

2.) Spilling powder:

a.) Slamming or going too fast with

the operating handle (#17071).

b.) Stick or pencil-lead type powders

bridging on the case mouth in the pow-

der funnel (#13005). See conversion

chart.

c.) Check powder bar adjustment.

3.) Erratic belling:

a.) Variation in case length. Divide

cases by brand.

b.) Handle not moving all the way

down on each stroke. Note: Try setting a

bullet on the case mouth in Station 6.

4.) Erratic powder charges:

a.) Powder bar not moving full length

of its travel. Turn the powder die down

until it does.

Station 7: Bullet Seating Problems

1.) Erratic seating depth of the bullet:

a.) Build up of lead shaving and/or

lube in the seater or crimp dies.

b.) Bullets having erratic dimension

(length and/or the ogive).

c.) Use the proper seating stem for the

type of bullet being used.

d.) Variations in case types and/or lots

– sort brass.

e.) Refer to a loading manual for prop-

er loaded length (OAL) and additional

information.

Station 8: Crimping Problems

1.) Erratic crimping:

a.) Length of cartridge cases erratic,

probably due to mixed brands of brass.

b.) Worn out or improperly made die,

use Dillon dies whenever possible.

2.) Loose bullet:

a.) Too much taper crimp. Note, this

condition also ruins accuracy.

b. Wrong expander (#12749*).

c.) Thin cases.

Maintenance

Loctite

Loctite should be used following

adjustments to or replacement of all

threaded screws. Please note that Loctite

should be applied to threaded portions

only and should be of a non-permanent

type. Blue Loctite #242 is recommended.

Swage

Clean the swage by pulling the operat-

ing handle down and use a small brush

to clean the tip. Every 10,000 rounds,

remove the swage rod (#20314 - large

or #20313 - small). and clean, lightly

grease and replace. Note: Do not grease

the tip of the swage where it contacts the

primer pocket.

20

primer punch

Super 1050, May 2007 5/21/07 12:00 PM Page 20