Dillon Precision Super 1050 User Manual

Page 17

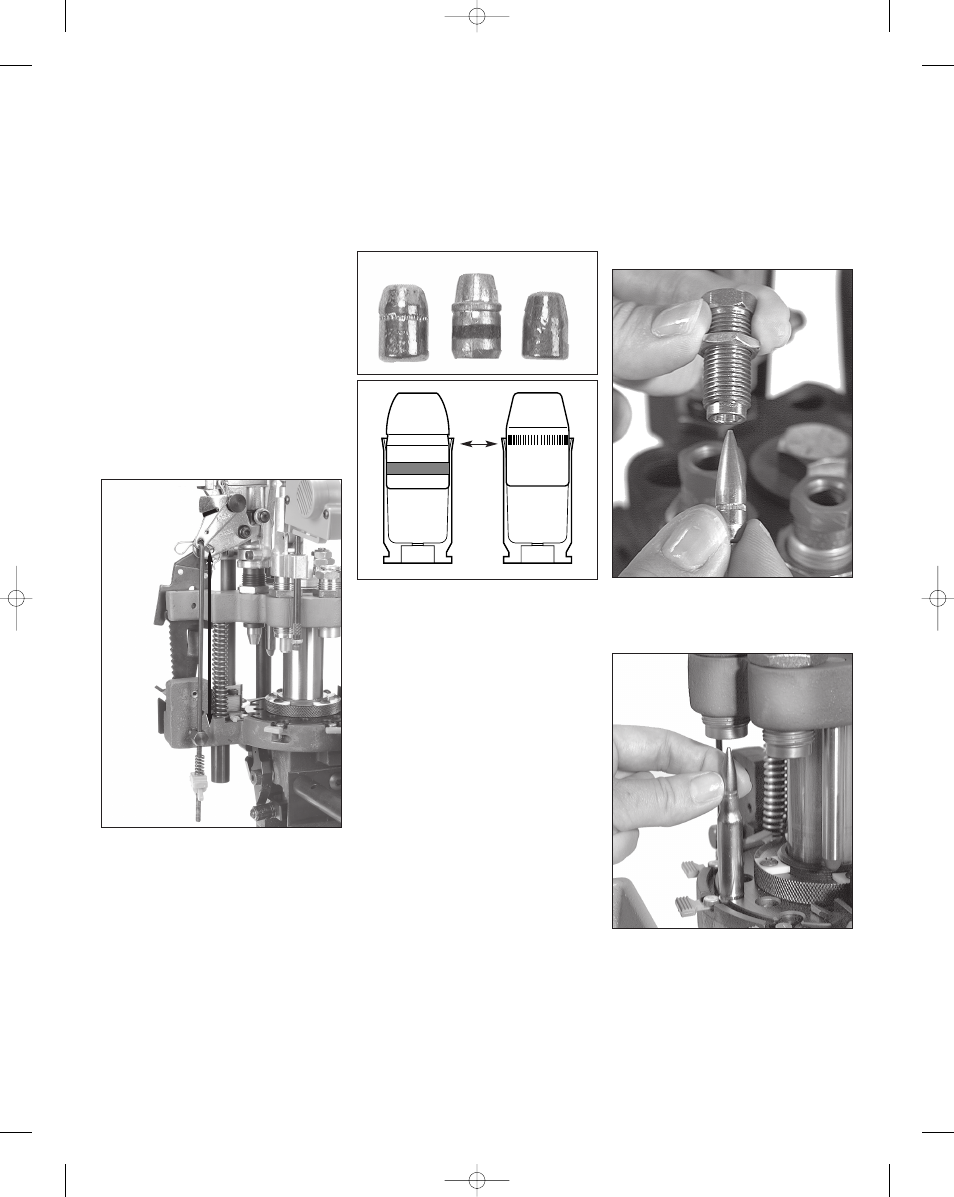

on the case mouth without falling off

and to keep the case from shaving lead

during the seating process - see the

illustration (above) example “B”.

Note: If you screw the die down too

far, the case will look like example "C"

in the illustration (right). You must then

discard this case, back the powder die

off, by turning it counter clockwise, and

continue with a new sized case.

You’ll soon learn to judge the correct

amount of bell by simply looking at it. In

the meantime, you might want to use

your dial calipers to check it. Twenty

thousandths of an inch greater (at the

mouth of the case) than its original

diameter, should about do it.

Once you’ve achieved the desired

amount of bell – with the case in Station

5, raise the toolhead. Run the lock ring

down hand tight.

Insure the bellcrank and the return rod

bolt (in the frame) FIG 54 are aligned.

Using a 5/32" Allen wrench, snug the

collar clamp screws.

While holding the powder measure in

place, snug the lock ring using a 1-1/8”

wrench.

Station 7 - General Information on

Bullet Seating

The purpose of the seating die is to

insert the bullet into the case and to push

it down into the case the proper amount.

How far the bullet is pushed into the

case will determine the overall length

(OAL). Several factors go into determin-

ing the proper OAL – such as, the maxi-

mum recommended OAL, listed in the

reloading manual, and the type of bul-

let being loaded. The type of bullet can

determine the OAL in one of two ways.

If the bullet has what is called a can-

nelure, or crimping groove Fig. 55 &

56, this will determine the proper OAL.

If the bullet you’re using doesn’t have a

cannelure or a crimping groove, then

you’ll need to refer to your reloading

manual for the suggested OAL. The pur-

pose of the cannelure and crimping

groove is to secure the bullet by giving

the mouth of the case a place to go

(without deforming the bullet) when

being crimped. When the bullet is

properly seated, the mouth of the car-

tridge case should be near the top of

the cannelure/crimping groove.

Refer to your reloading manual.

Under the section specified for the cal-

iber you’re loading, you’ll find a

schematic of the cartridge. For example,

.38 Special lists a maximum OAL of

1.55" (Lyman Reloading Handbook). If

you’re seating the bullet to the can-

nelure/crimping groove, the OAL should

be well within the maximum OAL listed,

however, use a set of dial calipers to

check it. (Dial calipers are available from

Dillon Precision). If the bullet you’re

using doesn’t have a cannelure/crimping

groove, refer to the specific type of bul-

let you’re using in the reloading manual.

For example – if you’re loading a 158 gr.

.38 Sp. JHP and it doesn’t have a can-

nelure/ crimping groove, use the suggest-

ed OAL of 1.480 (Lyman Reloading

Handbook).

Station 7 - Installation and Adjustment

of the Seating Die

Take the seating die from the die box

and screw it into Station 7. Screw the

die down until the bottom of the die is

flush with the bottom of the toolhead.

Note: At this point the die will not be

screwed down far enough to begin seat-

17

Fig. 55 & 56 - Shown are several examples

of a cannelure or crimping groove.

Fig. 54 - Make sure the bellcrank and return

rod bolt are aligned.

Figure 64

Figure 70

Figure 114

Please note that every die set includes

seating stems to fit most common bullet

types. Select the appropriate seating stem

for the bullet type you are loading.

Fig. 57 - Place the bullet on the case

mouth at Station 7.

Super 1050, May 2007 5/21/07 12:00 PM Page 17