Dillon Precision Super 1050 User Manual

Page 16

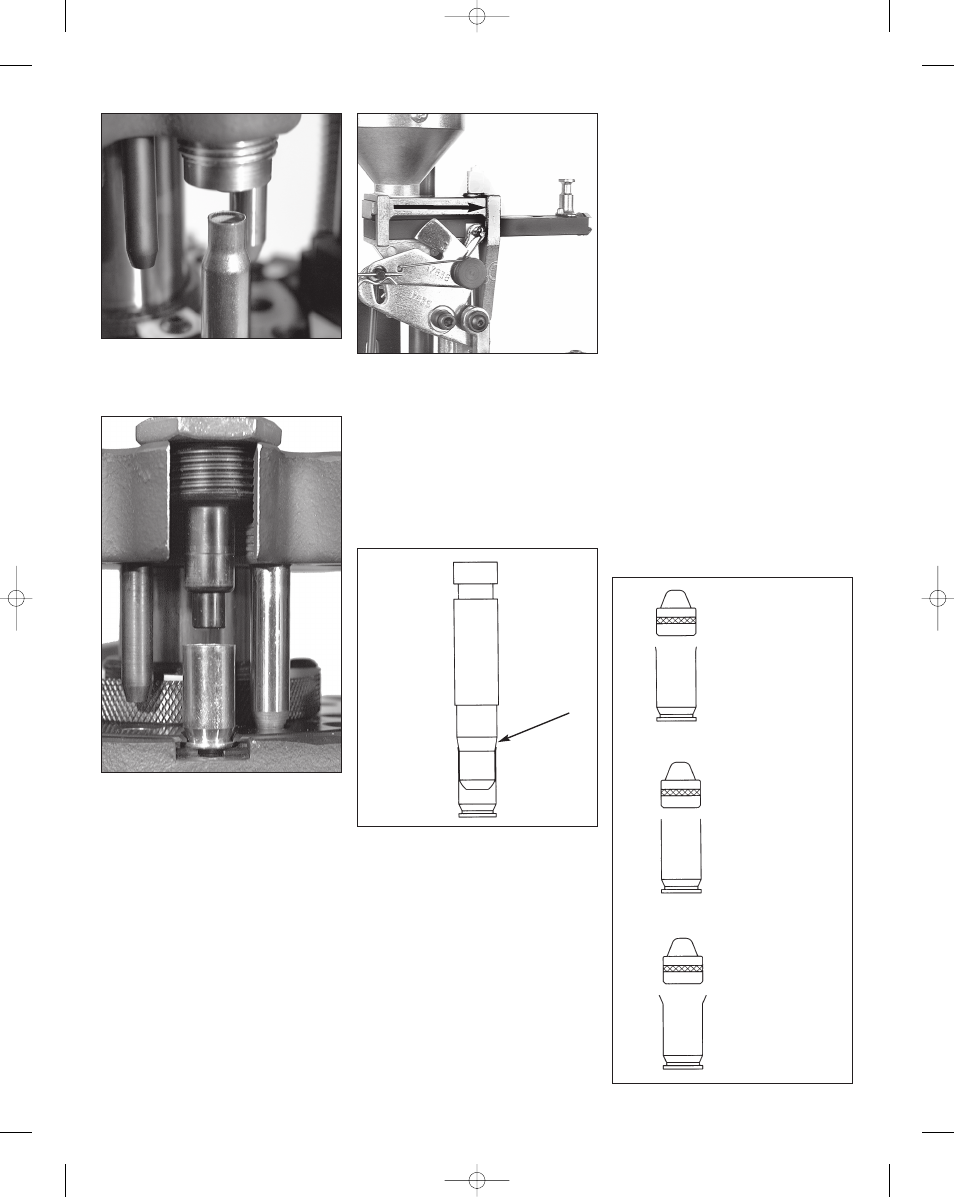

Station 5 - Adjustment of the Powder

Die/Powder Funnel

Note: Adjusting the powder die for

a straight wall case is not the same as

adjusting a powder die for a bottle-

necked case. This is because straight

wall cases are given a bell and bottle-

necked cases are not given a bell.

For the powder bar to properly dis-

pense a measured powder charge, the

powder bar must travel its full distance.

To travel its full distance, the white cube

must contact the powder measure body

(see arrow FIG 52).

Also the belling process does not

begin until after the powder bar has trav-

eled its full distance. The angled portion

on the bottom of the powder funnel (Fig.

53) is what bells the cartridge. Once the

white cube has contacted the powder

measure body the case is forced upward

against the tapered portion of the pow-

der funnel producing a bell. The more

the powder die is adjusted down (clock-

wise) the more the case will be belled.

Note: If the powder die is not adjusted

down far enough to cause the powder

bar to travel its full distance the powder

charge will be erratic and the case will

not receive enough bell.

Station 5 - Adjustment of the Powder

Die/Powder Funnel Cont...

Drop a case into the casefeed funnel

and cycle the handle twice. The case

should now be in the shellplate at

Station 2.

Move the handle down. Notice the

resistance at the end of the down stroke.

This is the resistance of the case in the

sizing die. Raise the handle. The case

will index to Station 3.

Cycle the handle to advance the case

to Station 4. Again, cycle the handle to

prime the case and index it to Station 5.

Cycle the handle.

If the white cube has not traveled its

full distance, raise the toolhead just

enough to pull the case off of the pow-

der funnel (this will prevent the

shellplate from indexing while you

adjust the powder die). While holding

the powder measure, turn the die down

1/8 of a turn. Again lower the toolhead

and observe the travel of the powder

bar.

Repeat as needed until the powder

bar travels its full distance, Fig. 52.

Once the powder bar travels fully

across you should continue to adjust

the powder die for the desired amount

of bell (turn the powder die 1/8 of a

turn at a time). The desired amount bell

is just enough to allow the bullet to sit

Fig. 51 - When properly adjusted, the

case mouth will go past the expanding

line and the stem will contact the bottom

of the case.

Fig. 52 - This photo shows the powder bar at

the end of its travel.

Fig. 53 - Adjusting the powder die up

reduces the amount of belling – down

increases the amount of belling.

A

Correct amount

of bell.

B

Not enough bell.

C

Too much bell.

16

Fig. 49 - You don’t need any more expansion

than what you see in this photograph.

Super 1050, May 2007 5/21/07 12:00 PM Page 16