Dillon Precision Super 1050 User Manual

Page 15

Casefeed Plunger Conversion

When changing calibers it may be

necessary to replace the casefeed

plunger (#13073*).

To do this, remove the clear casefeed

tube (#20533*) and pull out the colored

casefeed adapter (#13654*). The adapter

is taped for shipping purposes.

Remove the two housing screws

(#13815) and the casefeed adapter hous-

ing (#11006).

Place your hand on the plunger while

removing the roller bolt (#13333). This

will prevent the casefeed plunger and

spring from jumping out of the machine.

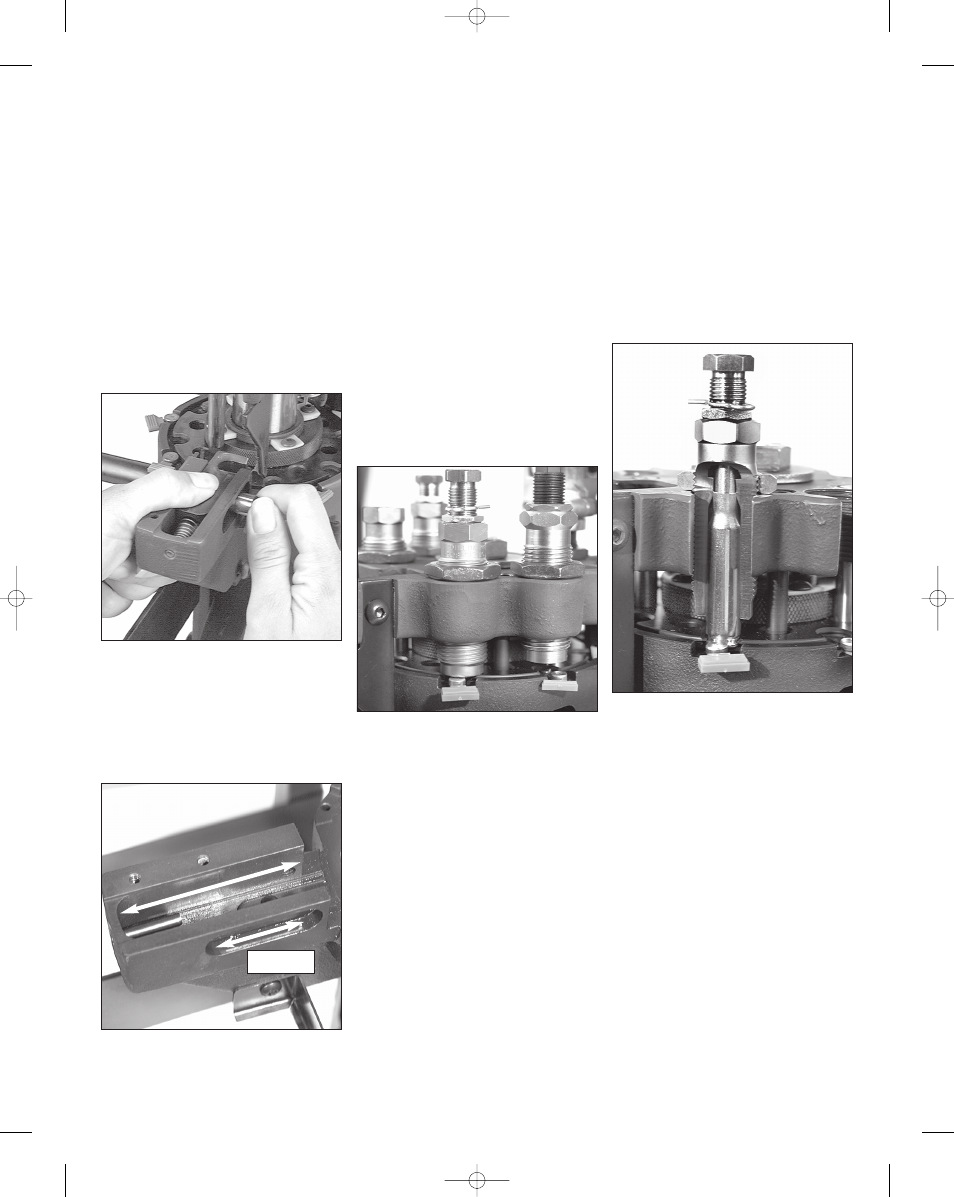

Fig. 45

Thoroughly clean the track and case-

feed parts with a solvent. Now very

lightly apply grease to the sides and

install the proper size casefeed plunger

(#13073*).

Fig. 46 Remember to

grease the roller (#13498) and the

roller track (

Fig. 46) and Loctite the

threads on the roller bolt (#13333).

Install the casefeed housing and insert

the proper size adapter (#13654*). The

casefeed tube (#20533*) should now be

inserted into the casefeed adapter

(#13654*). Note that the tube is marked

“up” on one end. Press this end into the

tube clip (#13859). See Troubleshooting

section for any adjustments.

Die Adjustments

Station 2 - To install the size/decap die

Warning: Never attempt to deprime

live primers, an explosion may result.

Move the toolhead down, by lowering

the handle all the way down.

Screw the sizing die into Station 2.

Continue to screw the die down until it

just touches the shellplate. Fig. 47

Tighten the die lock ring finger tight.

Now move the toolhead up by raising

the handle to its upright position.

Note: When loading .270 or .30-06

you need to raise the decap assembly so

that the hitch pin clip is a minimum of

1/8” above the silver lock ring as shown

in Fig. 47.

Place a case in the casefeed funnel.

Here, the case drops to the casefeed

plunger.

Cycle the handle. The casefeed cam

pushes the roller bushing back, dropping

the case into the slot of the plunger.

Cycle the handle. The case is inserted

into the shellplate.

Note: After raising the handle, insure

that you push the handle against its full

aft stop. This will insure that the

shellplate fully advanced to the next

station.

Note: When priming, pushing the

handle against its stop, will insure that

the primer is fully seated.

Again, move the toolhead down. The

case is now sized. If the case has a

spent primer, it will be deprimed.

Leave the toolhead in this position with

the case fully inserted in the die.

Fig.

48 This will ensure that the die

remains in alignment when tightening

the lock ring.

Using a 1" wrench to turn the lock

ring and a 7/8" wrench to hold the die

body, tighten the lock ring.

Station 3 - Adjustment of the Expander

Die

Install the expander die (caliber

specific) at Station 3. Place a case in

Station 2 and cycle the operating han-

dle once (sending the case to Station

3). Turn the expander die down until

you feel it make contact with the case

and cycle the operating handle. Make

adjustments in one-quarter turn incre-

ments until the desired expansion of

the case mouth is achieved. Tighten

the die lock ring.

A properly expanded case should

show a slight flare at the case mouth.

Fig. 49

15

Fig. 45 - The casefeed plunger and spring

are under tension. Hold them in place while

removing the roller bolt.

Fig. 46 - Be sure to lightly grease the sides

of the casefeed plunger track, casefeed

plunger and roller after cleaning.

roller track

Fig. 47 - Screw the size/decap die down

until it just touches the shellplate.

Fig. 48 - As the toolhead continues down,

it will reshape the case neck, shoulder

and body.

Super 1050, May 2007 5/21/07 12:00 PM Page 15