Dillon Precision Super 1050 User Manual

Page 21

21

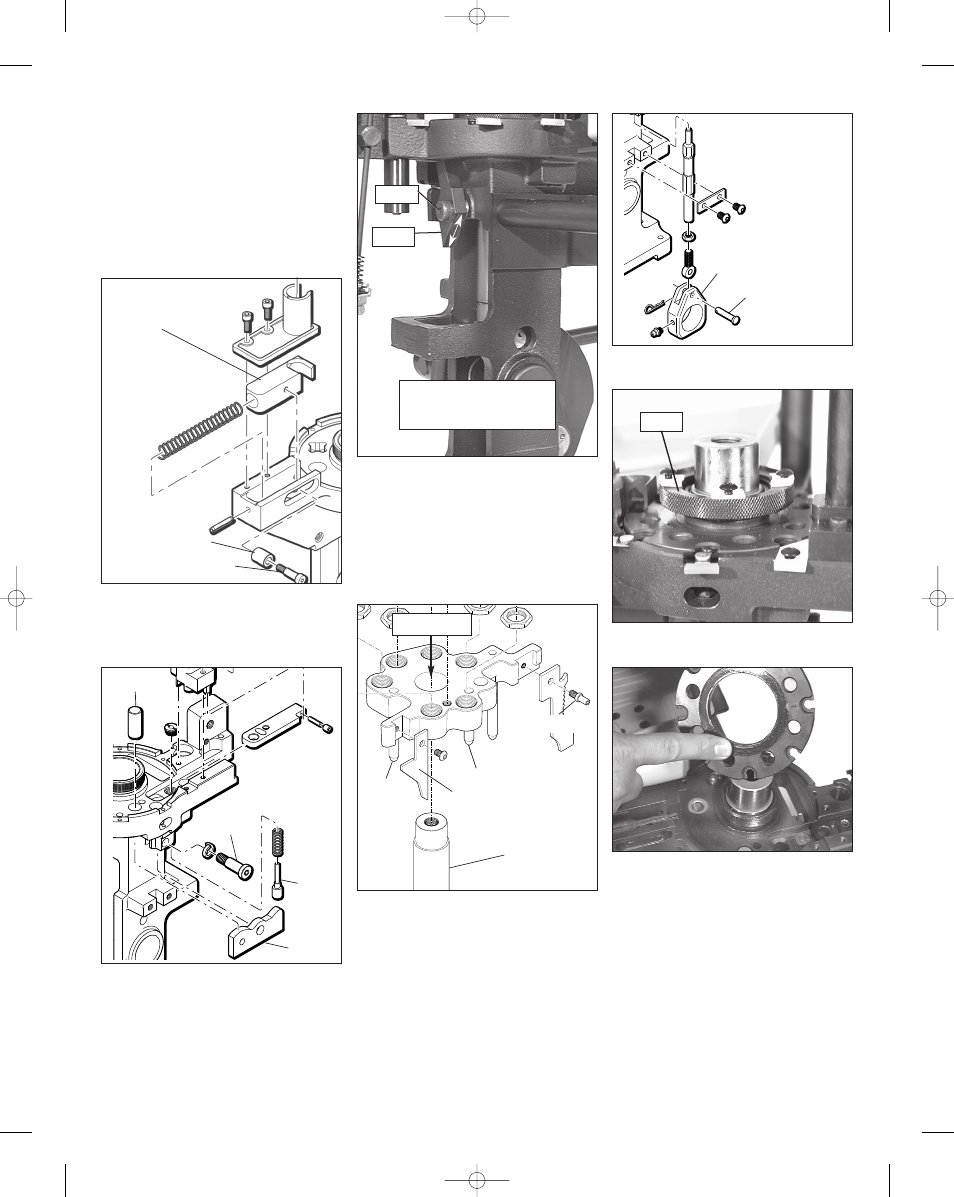

Lubrication

Operating circumstances will dictate

the frequency of required lubrication. It

is highly recommended that the Super

1050 be cleaned and lubed after every

10,000 rounds of operation.

Use a high-grade, conventional wheel

bearing grease – do not use oil.

Lubrication Points:

• Casefeed Plunger (#13073*), lube the

sides and bottom.

• Casefeed Plunger Roller (#13498) and

Bolt (#13333)

• Tappet (#12995)

• Rocker Arm (#13058), cam surfaces

and hole.

• Pivot Bolt (#13296)

• Primer Punch Base (#12849 - large or

#13307 - small)

• Lube the Indexing Lever Cam surface

(#10064) and Index Lever Shoulder

Bolt (#13276). With the handle in the

rest position, you will see the Index

Roller (#10996) come into contact

with the Lever Cam surface. The

Index Roller (#10996) also requires

periodic lubrication.

• Alignment Pins (#12972 & #13515

located under the toolhead)

• Cam Guide Bolt (#12486) and its

mated slot

• Toolhead Bore (#20420 - lightly to

avoid rusting and/or freezing up)

• Mainshaft Lubrication – Use only 30

weight motor oil. DO NOT use a

penetrating lubricant such as WD-40,

Breakfree, etc…

• Swage Connecting Rod (#13417) and

Clevis Pin (#13522)

• Shellplate lock ring (#20311), bottom

surface to shellplate face.

• Shellplate center hole. It’s easiest to

lubricate the shellplate center hole

when changing from one caliber to

another.

We recommend that you use a droplet

of Blue Loctite on the threads of the fol-

lowing bolts prior to reinstalling:

#13333, #13296, and #13276 (see pho-

tos and schematics).

casefeed plunger

(caliber specific)

13498

13333

12995

13296

13058

12849

large

or

13307

small

75% - 50% - 75% - 75%

12486

alignment pin

Super 1050 mainshaft

10999

toolhead bore

alignment

pin

casefeed cam

13417

13522

13276

11064

operating handle shown in

down position

20311

Super 1050, May 2007 5/21/07 12:00 PM Page 21