American Energy Systems Catalytic BBF User Manual

Page 26

26

CATALYTIC COMBUSTORS

Catalytic stoves contain catalytic combustors. Approximately 70% to 95% of the chemical energy contained in wood logs turns into

heat as they are burned in a conventional stove (assuming optimal operation.) If smoke (flue gas) does escape up the chimney without

being burnt, about 30% of the chemical energy is lost. This lost energy pollutes the chimney system and the atmosphere. The

catalytic combustor was designed to make use of this wasted chemical energy. The combustor makes uses of more of the chemical

energy by ensuring flue gases ignite at lower burn temperatures; therefore, the catalytic stove has the potential to: a) reduce chimney

creosote buildup, b) reduce air pollution, and c) reduce operating costs when compared to a conventional stove.

The catalytic combustor consists of a durable temperature resistant ceramic composition, which is extruded into a honeycomb shape.

This ceramic material is then fired and covered with a noble-metal catalyst. As smoke from the fire contacts the combustor, it ignites

at temperatures as low as 500

O

F. Flue gases normally ignite at 1,000

O

F. Country Flame recommends waiting until the probe

thermometer reaches 700°F before engaging the catalytic combustor. (Catalytic operation, called “light off,” will not occur until the

stove and catalyst exceeds 500°F to 700°F.) The Catalytic Bypass Rod must be disengaged to allow flue gases to bypass the catalytic

combustors until the stove’s firebox reaches approximately 700°F, the temperature necessary to sustain combustor light off.”

CATALYTIC BYPASS ROD

The catalytic bypass rod determines whether exhaust emissions travel up the chimney unimpeded or pass through the catalytic

combustor to be cleaned on the way to the chimney. On Country Flame models, the catalytic combustor should be disengaged (pulled

out on some models and pushed in on some models) when the fire is started. This allows combustion gases to bypass the catalytic

combustors. As the stove reaches approximately 700°F the catalytic bypass rod should be engaged (pulled out on some models and

pushed in on some models) thus closing off the flue and forcing all combustion gas to pass through the combustor. The catalytic

bypass rod should always be disengaged when loading or reloading the stove with additional wood fuel.

BLOWER UNITS

Blowers circulate room air through and around the catalytic stove to provide additional heating capability to the home. Refer to

TABLE 5 and TABLE 6 to determine whether a blower is standard or optional on the unit purchased. The blower is designed to pull

cool room air into and through the hot stove and back out into the room to provide additional heating value from the stove. Refer to

blower specifications on a specific model for specific types and operation of each blower. A stove’s firebox should reach proper

operating temperature in order to minimize emissions and improve operating efficiency; therefore, a room air blower system should

not be operated for at least 30 minutes after starting a fire. (This information is not applicable to catalytic stoves that do not include an

optional blower system.)

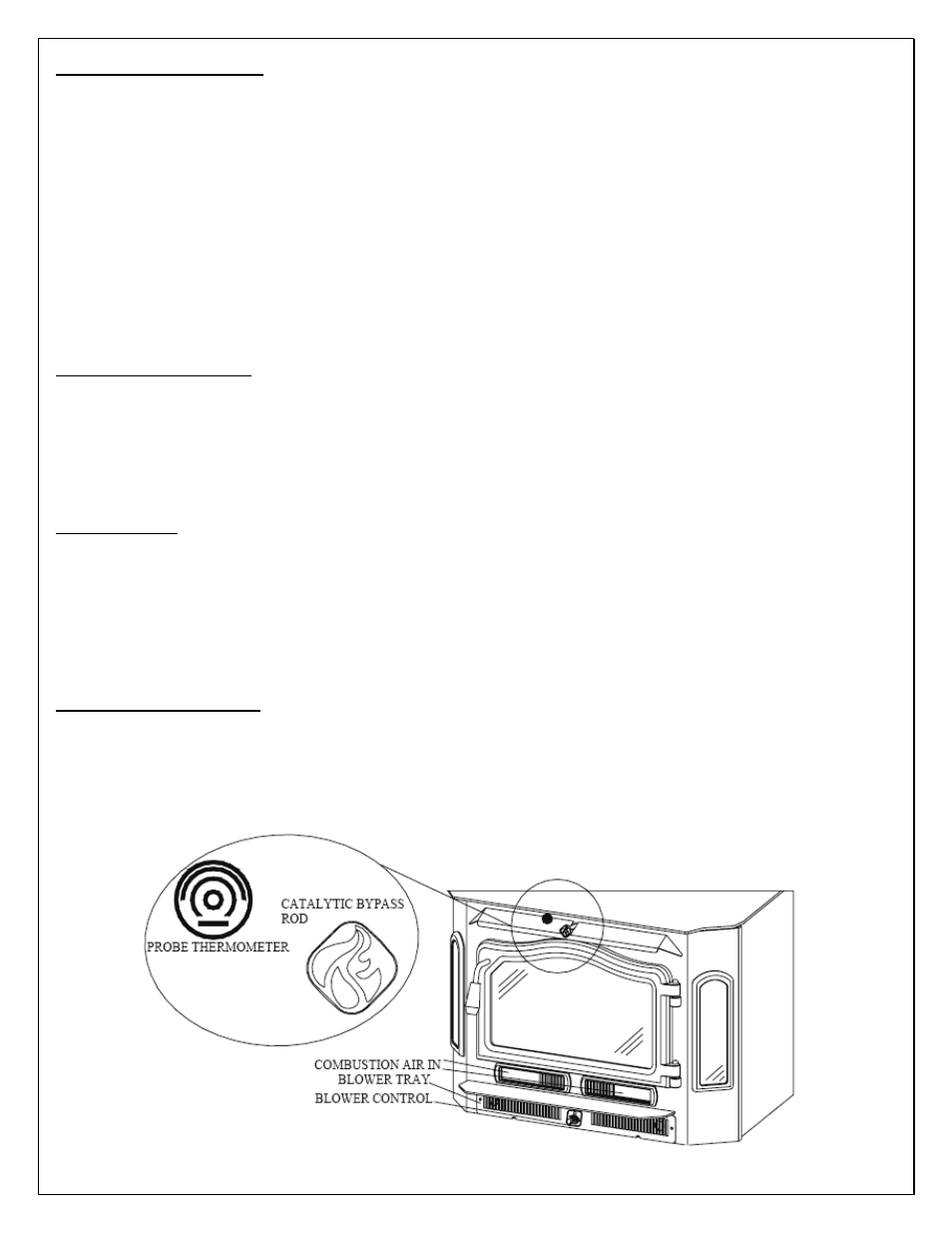

8” PROBE THERMOMETER

A probe thermometer is provided with each catalytic stove. This probe thermometer is used to measure the temperature at the

catalytic combustor. Replacement probe thermometers are available from Country Flame or a local authorized dealer. The probe

thermometer is installed directly above the hood and slightly to the left of the air bypass damper on the top left face of the stove.

Refer to FIGURE 15 for the proper location of the probe on the face of the stove.

FIGURE 15: PROBE THERMOMETER