V. electrical connections, A. high-voltage connections, Figure 11 —high- & low-voltage connections – Bryant 585B User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

junction with all applicable criteria presented in this section of

the unit Installation Instructions.

NOTE:

The minimum installation requirements of the duct

system must be in accordance with the standards of the Na

tional Fire Protection Association for installation of air con

ditioning and ventilating systems of other than residence-

type, NFPA No. 90; or residence-type, warm-air heating and

air conditioning systems, NFPA No. 90B; and/or local codes

and ordinances.

The following criteria must be followed when selecting, siz

ing, and installing ductwork:

1. Ductwork, registers, and return-air grilles should be

selected and sized according to ASHRAE recommenda

tions and as presented in BDP training materials.

CAUTION:

When drilling duct flange fastening holes in the

unit side, use care to avoid puncturing the evaporator coil.

2. Ductwork can be screwed or bolted to unit duct flanges.

Use suitable gaskets to insure airtight seal.

3. External fleld-supplied air Alter must be installed in re-

turn-air ductwork. Recommended sizes for filters are

shown in Table I. Install filters where they are easily ac

cessible for service.

NOTE:

Accessory plenums and horizontal economizers have

factory-supplied, high-capacity filters.

4. Avoid abrupt duct size increases and reductions.

5. Provide supply and return ductwork with an approved

vibration eliminator.

6. Adequately insulate and weatherproof all ductwork

located outdoors. Ducts passing thru unconditioned

space must be insulated and covered with vapor barrier

in accordance with latest issue of SMACNA and NESCA

minimum installation standards for heating and air

conditioning systems.

7. Secure all ducts to building structure.

8. All openings in building structure must be properly

flashed, weatherproofed, and vibration-isolated in ac

cordance with local codes and good building practices.

V. ELECTRICAL CONNECTIONS

WARNING:

The unit cabinet must have an uninterrupted or

unbroken electrical ground. This can consist of electrical

wire connected to the ground lug in the control box or con

duit approved for electrical ground, when installed in ac

cordance with existing electrical codes.

CAUTION:

Copper conductor is the only type of wire that is

to be connected between the electrical disconnect and the

unit. Do not use aluminum wire.

Operation of the unit on improper line voltage, or with ex

cessive phase imbalance, constitutes abuse and is not

covered by warranty.

All electrical connections must be made in accordance with

the National Electrical Code and local electrical codes

governing such wiring.

The unit must be electrically grounded in accordance with

the National Electrical Code, ANSI CI-1975, when an exter

nal electrical source is utilized.

A separate electrical line with a fused disconnect switch

mounted at, or within sight of, the unit should be used for

this installation. Refer to the unit rating plate for maximum

fuse size. See Table II, III, or IV for recommended wire sizes

and lengths.

WARNING:

Label P/N A-74191B, which is shipped loose in

bag of parts, must be affixed to the electrical disconnect box.

This label states: “Do not disconnect the electrical power to

this appliance without first turning off the gas supply.”

NOTE:

Fused disconnect may be mounted directly on con

trol corner panel. To mount disconnect on this panel, align

disconnect box knockout with unit high-voltage inlet hole

and secure box to panel. Route wiring from disconnect

through aligned knockout and unit inlet.

CAUTION:

Ensure that the drill does not damage any com

ponents when drilling through the panel.

NOTE:

If aluminum conductor is used from the electrical

service to the disconnect switch where local codes permit the

use of aluminum wire, the connections must be made in ac

cordance with the National Electrical Code. In preparing the

wire, just before installing the connector, all aluminum wire

must be “brush-scratched” and then coated with a corrosion

inhibitor, such as Pentrox A. When it is suspected that the

connection will be exposed to moisture, it is very important

to cover the entire connection completely to prevent an

electrochemical action that will cause the connection to fail

very quickly. Reducing the effective size of the wire, such as

cutting off strands so that the wire will fit a connector, is

very poor practice. Properly sized connectors should be used.

CAUTION:

If aluminum conductors are to be used, the wire

gauge selected must have current capacity not less than the

copper wire specified and must not create a voltage drop be

tween the service panel and the unit in excess of 2% of the

unit rated voltage.

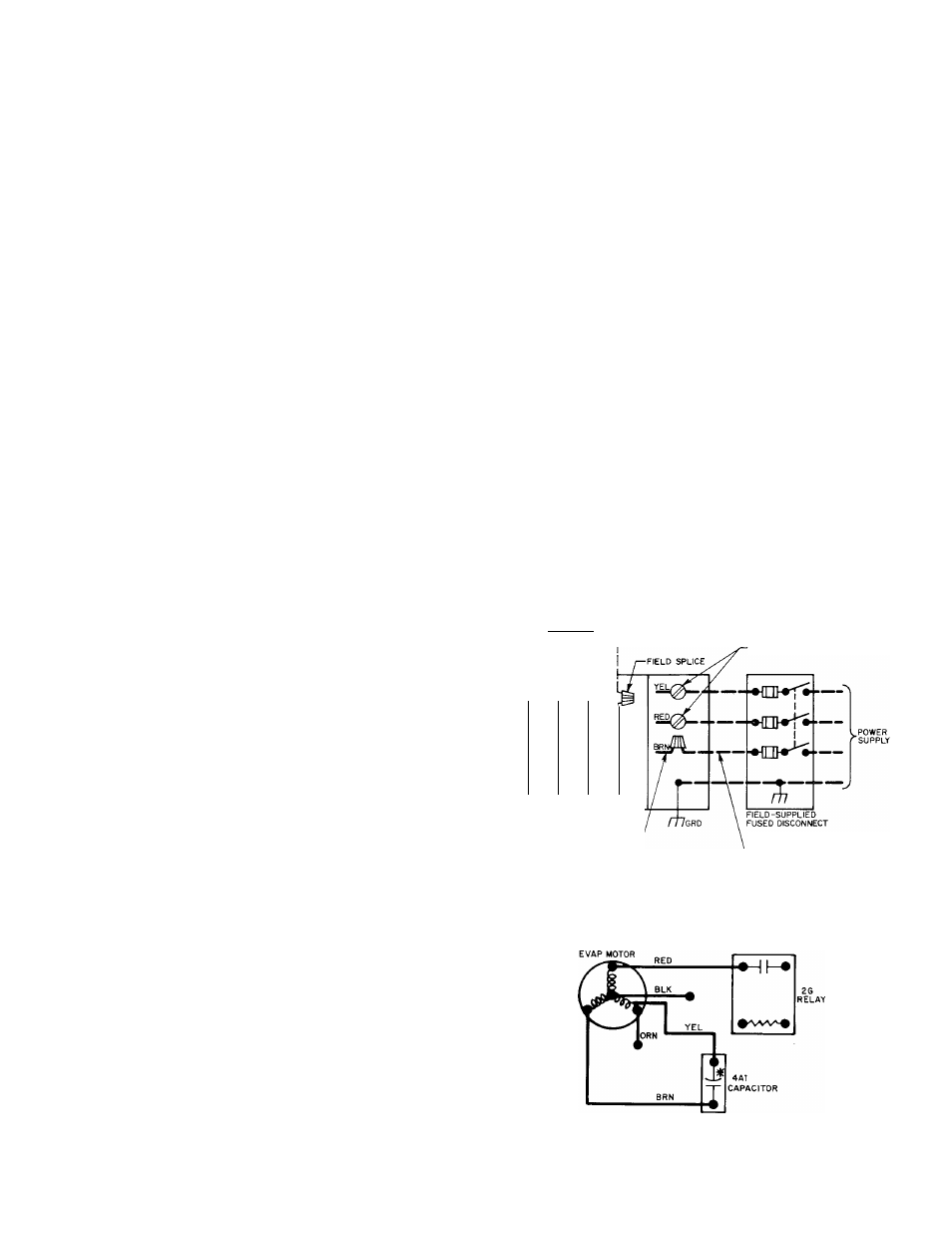

A. High-Voltage Connections

Proceed as follows to complete high-voltage connections:

1. Run high-voltage leads from fused disconnect through

high-voltage inlet hole provided in control corner panel.

See Figure 2 for location of panel and hole.

2. Run high-voltage leads into unit control box and con

nect leads to contactor. See unit wiring label and Figure

11

.

SINGLE-STAGE HEAT a COOL-MANUAL CHANGEOVER

( p Q

THERMOSTAT P/N 344270030 {SUBBASE INCLUDED)

OR

THERMOSTAT P/N PS2758-l(OR-2) WITH

SUBBASE P/N PS2759-34

CONTACTOR TERMINALS

3

3

3

_»

llJ

>-

D

OD

Q

or

LOW-VOLTAGE PIGTAIL LEADS

CONTROL BOX

HIGH-VOLTAGE

PIGTAIL LEAD

3-PHASE

UNITS ONLY

FIELD LOW-VOLTAGE WIRING

FIELD HIGH-VOLTAGE WIRING

FACTORY LOW-VOLTAGE WIRING

FACTORY HIGH-VOLTAGE WIRING

note

: FOR AUTOCHANGEOVER

APPLICATIONS, USE THERMOSTAT

FyN 34427D52 OR PS3108A

WITH SUBBASE P/N PS3109E

note

; SET HEAT ANTICIPATOR

AT 0.85 AMPS

A76313

Figure 11 —High- & Low-Voltage Connections

A77375

Figure 12—Evaporator Motor Connections

for 208-V Operation of

Sizes 018050 & 024050

-7-