Table vim-heating service analysis chart, Ix. care and maintenance, A. air filter – Bryant 585B User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

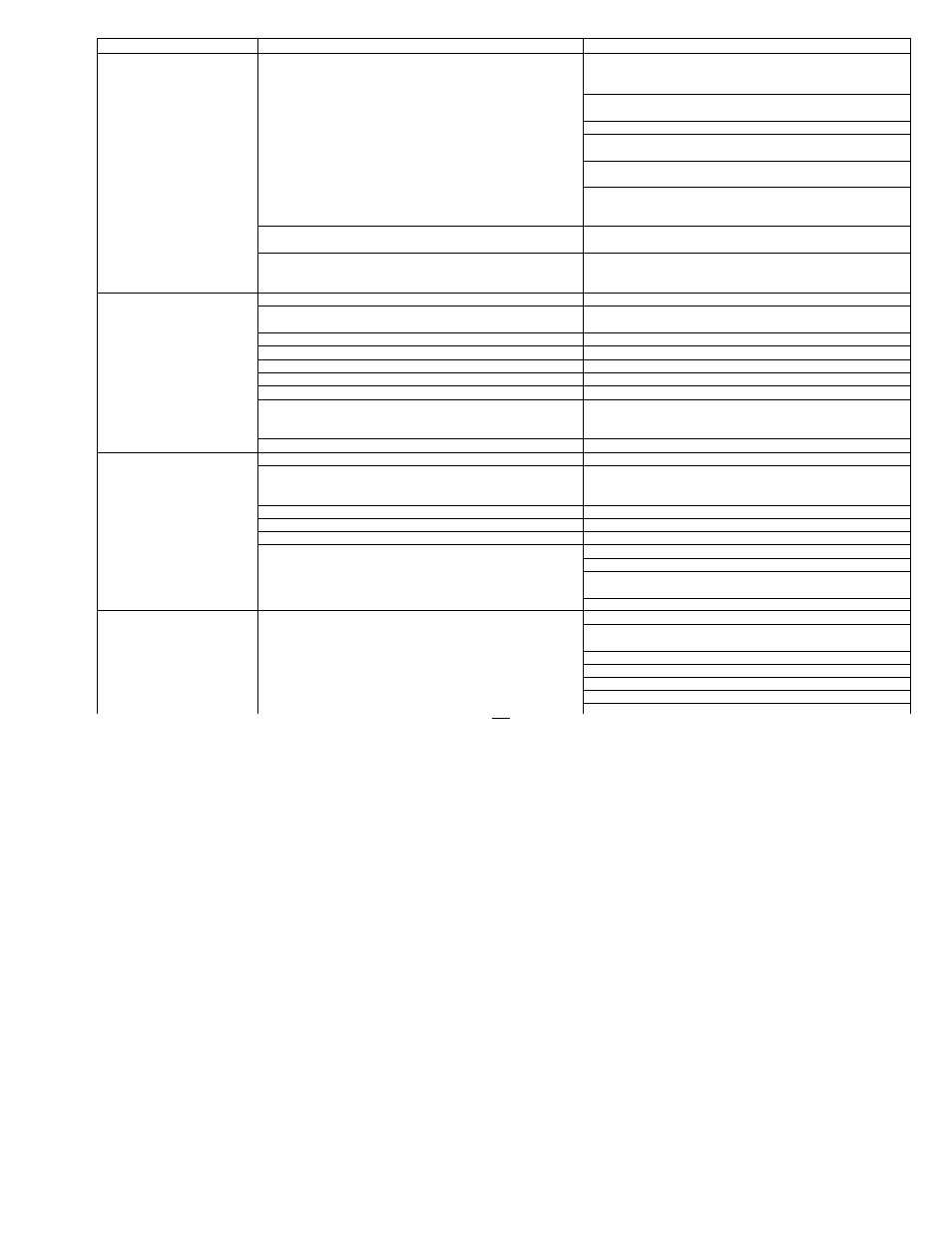

TABLE VIM-HEATING SERVICE ANALYSIS CHART

SYMPTOM

CAUSE

REMEDY

Pilot will not light.

No spark at electrode

Check air gap between electrode tip and pilot

burner. Gap should be 1/8-in. ± 1/16 in.

Readjust as necessary.

Check moisture or dirt accumulation on electrode

ceramic— clean ceramic with cloth.

Cracked ceramic— replace pilot electrode assembly.

Check for loose or broken wiring at and between

control and electrode— replace wire as necessary.

Check fuses or circuit breaker to insure voltage

to unit.

Check 24-volt input to igniter control. If

you find 24 volts and the above remedies have been

explored, replace igniter.

Spark shorting out to main burner

Realign electrode tip away from main burner

but maintain spark gap to pilot burner.

No gas at pilot burner

Check to see if pilot valve is opening. Check for

loose or broken wiring connections. If no

deficiency is found, replace gas valve.

Burners will not ignite.

W ater in gas line

Drain — install watertrap.

No powerto furnace

Check power supply, fuses, wiring, or

circuit breaker.

No 24-volt power supply to control circuit

Check transformer— replace if necessary.

Miswired or loose connections

Check all wiring and wirenut connections.

Dirty pilot— yellow flame

Clean pilot orifice.

Pilot burning properly— sharp blue flame

Replace pilot.

Burned out heat anticipator in thermostat

Replace thermostat.

No gas at main burners

Check to see if main gas valve is opening. Look

for loose or broken wiring connections. If

no deficiency is found, replace valve assembly.

Broken thermostat wire

Run continuity check to locate break.

Inadequate heating

Dirty air filter

Replace filter.

Gas input to furnace too low

Check gas pressure at manifold. Clock gas meter

for input. If too low, increase manifold

pressure, or replace with correct orifices.

Unit undersized for application

Replace with properunit— oradd additional unit.

Restricted airflow

Clean or replace filter— or remove any restriction.

. Blower speed too low

Use faster speed tap— or install optional blower.

Limit switch cycles main burners

OFF setting of fan control set too high — reset.

Dirty air filters— clean or replace.

Registers closed, restricted ductwork— open

or remove restriction.

Check heat anticipator setting on thermostat— readjust.

Poor flame characteristics

Incomplete combustion results in:

Aldehyde odors, (CO), sooting flame— floating flame

Air shutters on burners closed— adjust to soft blue flame.

Check all screws around flue outlets and burner

compartment— tighten.

LACK OF COMBUSTION AIR.

Cracked heat exchanger— replace.

Overfired furnace— reduce input, or change orifices.

Check vent for restriction— clean as required.

Check orifice to burner alignment.

2D close and complete the circuit through the compressor

motor 3F and condenser fan motor 3D1, causing both motors

to start instantly.

All motors will continue to run and the cooling cycle will re

main “on” until the room thermostat is satisfied. When the

conditioned space temperature drops to the thermostat set

ting, the electrical connection from terminal R to terminals

Y and G is opened in the thermostat. This open circuit

deenergizes the compressor contactor coil 2D and the cooling

blower relay coil 2C. The blower, condenser, and compressor

motors will stop. The cooling will remain “off” until there is

another demand for cooling by the thermostat.

IX. CARE AND MAINTENANCE

WARNING:

Never place anything combustible on or in con

tact with the unit.

Disconnect all electrical power to unit before performing

any maintenance or service on unit.

To ensure continuing high performance, and to minimize

possible equipment failure, it is essential that periodic main

tenance be performed on this equipment. Consult your local

Dealer as to the proper frequency of maintenance and the

availability of a maintenance contract.

WARNING:

As with any mechanical equipment, personal

injury can result from sharp metal edges, etc.; therefore, be

careful when removing parts.

Because of possible damage to the equipment or personal in

jury, maintenance should be performed by qualified persons

only.

The ability to properly perform maintenance on this equip

ment requires certain mechanical skills and tools. If you do

not possess these, contact your Dealer for maintenance.

The minimum maintenance that should be performed on

this equipment is as follows:

1. Check air filter each month. Clean or replace as re

quired.

2. Check cooling coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean as necessary.

3. Check blower motor and wheel for cleanliness and

lubrication each heating and cooling season. Clean and

lubricate as necessary.

4. Check electrical connections for tightness and controls

for proper operation each heating and cooling season.

Service as necessary.

A. Air Filter

CAUTION:

Do not operate the unit for any period of time

without having a suitable filter in place in the return-air

duct system. Always replace filter with same size and type.

Filters are not provided as an integral part of the unit. A

filter must be used with the unit and must be inspected fre

quently. When the filter becomes clogged with dust and lint,

it should be replaced (disposable-type) or cleaned (cleanable-

type). The filter should be inspected at least once each

month, and replaced or cleaned at least twice during the

year (more often, if necessary).

-13-