A. checking components – Bryant 585B User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

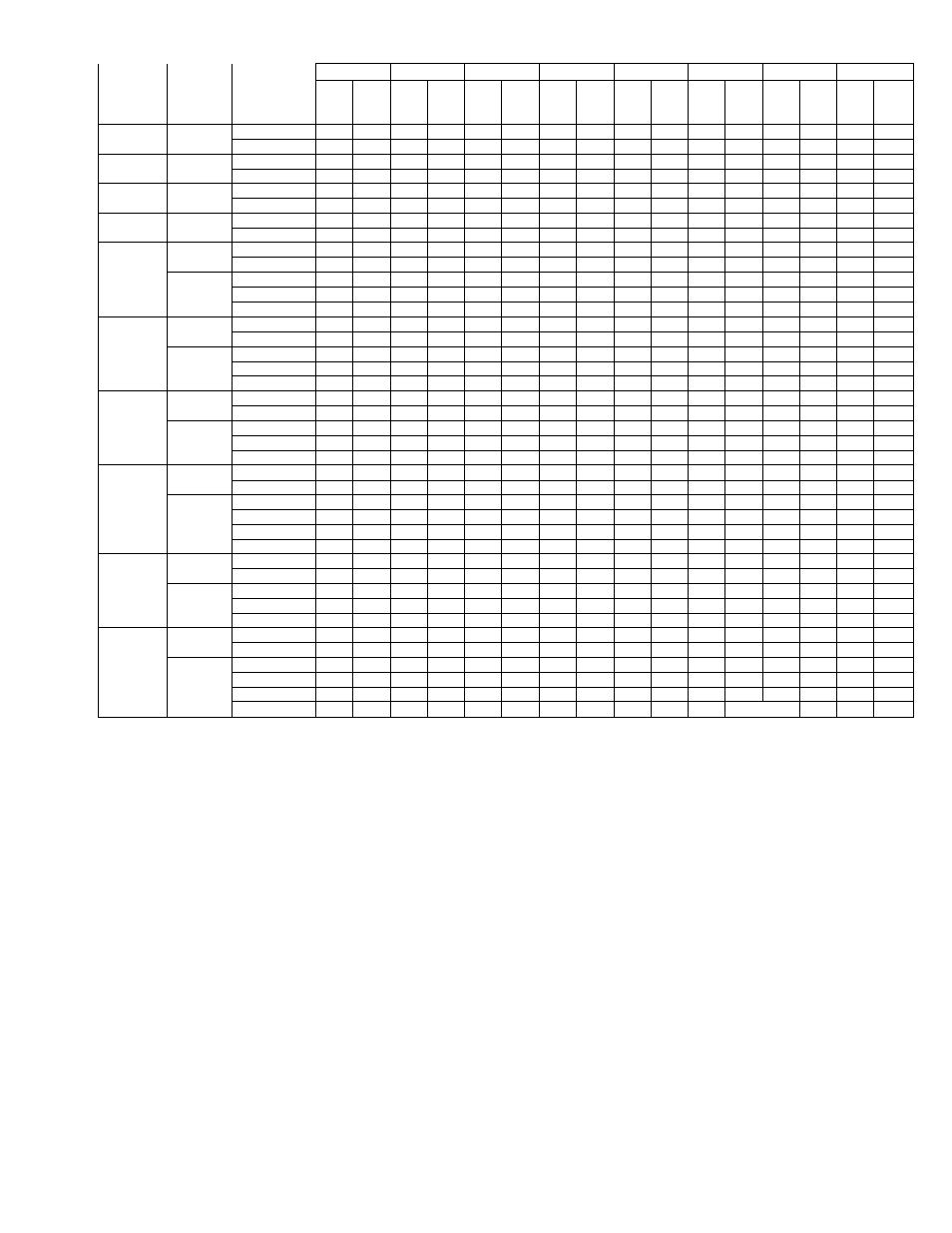

TABLE VII-AIR DELIVERY (FtVMin) AT INDICATED EXTERNAL STATIC

PRESSURE & VOLTAGE WITHOUT FILTER*

External Static Pressure—Inches wc

585B

Size

Volts-

Phase

160 Hzl

Application

Motor Speed

Settingt

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

208V

230V

or

460V

208V

230V

or

460V

208V

230V

or

460V

208V

230V

or

460V

208V

230V

or

460V

208V

230V

or

460V

208V

230V

or

460V

208V

230V

or

460V

018050

208-&

230-1

Heating-L

—

725

765

705

730

685

695

650

645

620

—

—

—

—

—

—

Cooling-L

—

715

745

695

715

670

670

640

615

590

_

—

—

—

—

—

024050

208-&

203-1

Heating-L

—

725

765

705

730

685

695

650

645

620

580

—

—

—

—

—

Cooling-H

—

900

930

865

885

825

840

775

780

720

710

—

—

—

—

—

024075

208-&

230-1

Heating-M

955

1030

925

1000

890

960

855

920

810

875

—

820

—

—

—

—

Cooling-L

830

910

805

885

775

855

740

820

700

780

—

730

—

—

—

—

030075

208-&

230-1

Heating-M

—

—

925

1000

890

960

855

920

810

875

765

820

—

—

—

—

Cooling-H

—

—

1165

1200

1100

1140

1045

1080

975

1010

905

930

—

—

—

—

036075

230-1

Heating-L

—

1185

—

1150

—

1125

—

1085

—

1035

—

975

—

—

—

—

Cooling-H

—

1495

—

1430

—

1360

—

1280

—

1205

—

1125

—

—

—

—

208-,

230-, or

460-3

Heating-L

—

—

1370

1410

1350

1390

1320

1360

1260

1300

1195

1230

1110

1145

1020

1050

Cooling-L+

—

—

1360

1400

1335

1375

1285

1325

1220

1260

1145

1180

—

1080

—

—

Cooling-H

1465

1510

1355

1395

1230

1265

1085

1120

036125

230-1

Heating-H

—

1640

—

1605

—

1545

—

1485

—

1425

—

1345

—

—

—

—

Cooling-L

—

1395

—

1355

—

1320

—

1275

—

1215

—

1125

—

—

—

—

208-&

230-3

Heating-Lt

—

—

1580

1630

1545

1595

1505

1550

1460

1505

1405

1450

1320

1360

1195

1230

Heating-M

—

—

1930

1990

1860

1920

1795

1850

1715

1770

1620

1670

1515

1560

1375

1420

Cooling-L

1435

1480

1370

1410

1260

1300

1115

1150

042100

230-1

Heating-L

—

1415

—

1375

—

1340

—

1295

—

1245

—

1175

—

—

—

—

Cooling-H

—

1620

—

1575

—

1515

—

1455

—

1385

—

1300

—

—

—

—

208- or

230-3

Heating-L

—

—

1600

1630

1565

1595

1520

1550

1475

1505

1420

1450

1335

1360

1205

1230

Cooling-Li

—

—

1580

1610

1540

1570

1500

1530

1450

1480

1380

1410

1275

1300

—

—

Cooling-M

1685

1720

1590

1620

1470

1500

1315

1340

048125

230-1

Heating-L

—

1460

—

1425

—

1390

—

1350

_

1305

—

—

—

—

—

_

Cooling-H

—

1760

—

1700

—

1640

—

1575

—

1490

—

—

—

—

—

—

208-,

230-, or

460-3

Heating-Lt

—

—

1600

1630

1565

1595

1520

1550

1475

1505

1420

1450

1335

1360

1205

1230

Heating-M

—

—

1950

1990

1880

1920

1815

1850

1735

1770

1635

1670

1530

1560

1390

1420

Cooling-Mt

—

—

1920

1960

1850

1885

1775

1810

1685

1720

1590

1620

1470

1500

—

—

Cooling-H

—

—

—

—

—

—

1940

_

1835

1870

1725

1760

1615

1650

1490

1520

060125

230-1

Heating-L

—

1750

—

1715

—

1675

—

1630

—

1590

—

1520

—

—

—

—

Cooling-H

—

2175

—

2110

—

2035

—

1950

—

1850

—

1735

—

—

—

—

208-,

230-, or

460-3

Heating-L

—

—

1665

1700

1610

1645

1560

1590

1490

1520

1400

1430

1315

1340

1215

1240

Cooling-Mt

—

—

2100

2145

2025

2065

1930

1970

1835

1870

1725

1760

—

—

—

—

Cooling-H

—

—

—

—

2425

2475

2330

2380

2225

2270

2090

2135

1955

1995

1820

1855

060150

230-1

Heating-M

—

2050

—

1995

—

1940

—

1870

—

1795

—

1690

_

—

—

Cooling-H

—

2175

—

2110

—

2035

—

1950

—

1850

—

1735

—

—

—

_

208-or

230-3

Heating-Lt

—

—

1665

1700

1610

1645

1560

1590

1490

1520

1400

1430

1315

1340

1215

1240

Heating-M

—

—

2155

2200

2075

2115

1990

2030

1895

1935

1795

1830

1680

1715

1570

1600

Cooling-Mt

—

—

2100

2145

2025

2065

1930

1970

1835

1870

1725

1760

—

—

—

Cooling-H

-

-

-

-

2425

2475

2330

2380

2225

2270

2090

2135

1995

1995

1820

1855

NOTE: For air delivery data applicable to size 036075 thru 060150 single-phase units with a field-installed, high-static blower, refer to the air delivery data for the

equivalent size 3-phase unit.

NOTE: 460-V units operate on the same motor speed for both heating and cooling, and are factory-set on the indicated cooling speed.

* Deduct field-supplied filter pressure drop to obtain available static pressure for ducting.

t Heating airflow values are with dry coil. Cooling airflow values are with wet coil.

iThese motor speed settings require a field wiring change. All other settings indicated are the factory setting.

— Indicates portions of the table that are beyond the recommended operating range or that are not applicable.

WARNING/DANGER:

Failure to follow these instructions

could result in serious personal injury:

1. Follow recognized safety practices and wear protective

goggles;', '7',

2. Do not operate compressor or provide any electric power

to this unit unless compressor terminal cover is in place

and secured.

3. Do not remove terminal cover until all electrical sources

have been disconnected.

4. If refrigerant leak is suspected around compressor ter

minals, relieve all pressure from system before touching

or disturbing anything inside terminal box.

System contains oil and refrigerant under pressure. Do not

use torch to remove any component. Wear your protective

goggles. To remove a component: ,

1. Shut oif electrical power to unit.

2. Relieve all pressure from system.

3. Gut connecting piping with tubing cutter.

4. Remove component from unit.

5. When necessary, unsweat remaining piping stubs

carefully. Oil may ignite when exposed to torch flame.

A. Checking Components

Perform the following steps before starting the unit.

1. Check for correct position of condenser fan blade in unit

top panel. See Figure 3.

2. Leak-test all refrigerant circuit connections to make

certain that none has been damaged in shipment.

3. Check entire system for leaks at all connections, includ

ing evaporator coil located in blower compartment. (Use

electronic leak detector, halide torch, or liquid-soap

solution.)

NOTE:

The cooling section is fully charged with refrigerant,

tested, and factory-sealed.

There should be no need to

check refrigerant charge if no leaks were found.

In rare

instances, when the refrigerant charge has been lost be

cause of a leak caused by shipping damage or a refrigerant

leak has been found, proceed as follows:

WARNING:

Never attempt to repair any soldered connec

tion while system is under pressure. Severe bodily injury

may result.

a. Locate and repair leak.

-11-