B. lubrication, C. evaporator and condenser coils, D. condensate drain – Bryant 585B User Manual

Page 14: E. evaporator blower, F. condenser fan, G. electrical controls and wiring, H. refrigerant circuit, I. cleaning the heating section, Bliject::ihtp'frpvpl:^ihg!:i,fhhife, Nbt'i poke' .stitsss

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

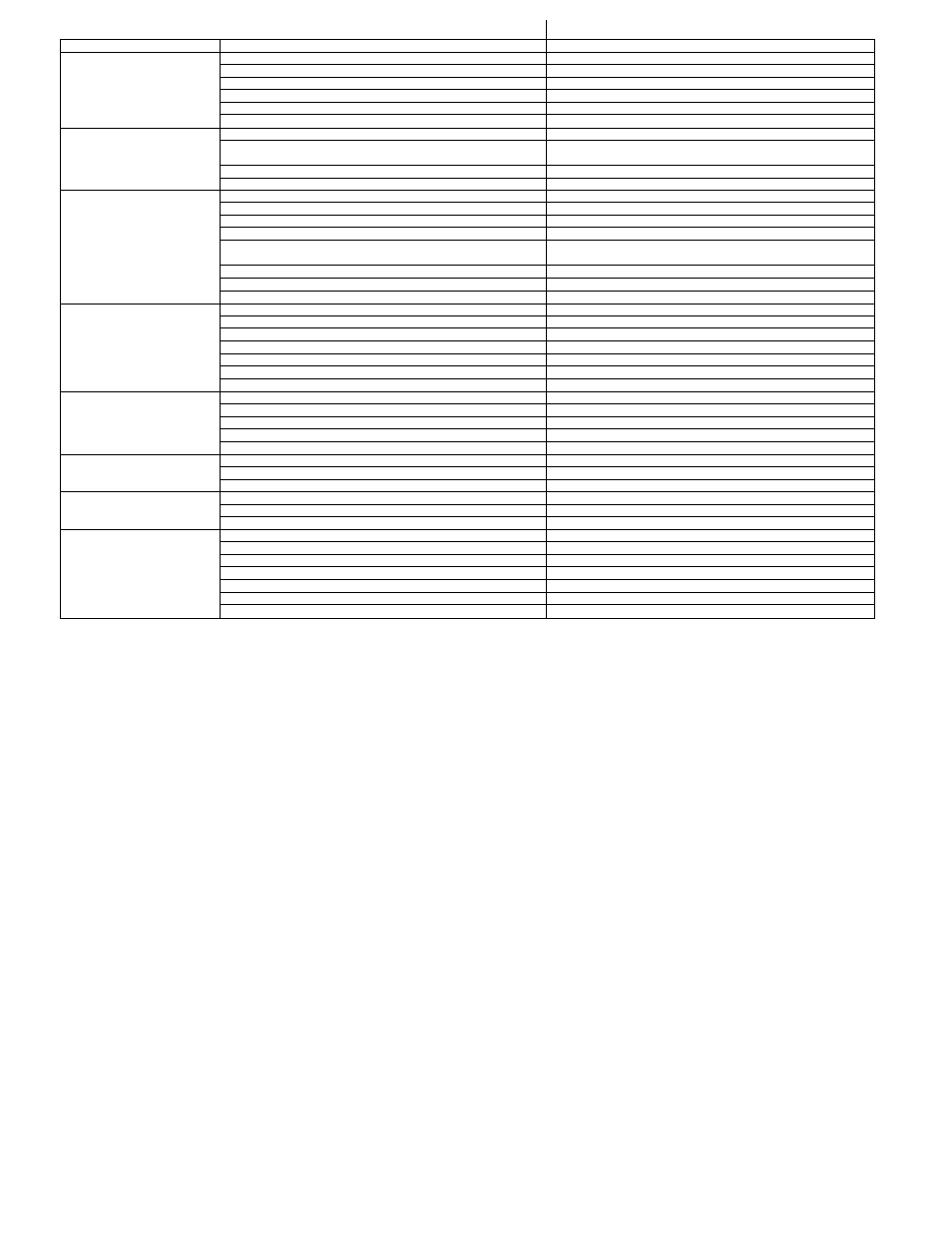

TABLE IX-COOLING SERVICE AN ALYSIS CHART

SYMPTOM

CAUSE

REMEDY

Compressor and condenser

fan will not start.

Power failure

Call power company.

Fuse blown or circuit breaker tripped

Replace fuse or reset circuit breaker.

Defective thermostat, contactor, transformer, or control relay

Replace component.

Insufficient line voltage

Determine cause and correct.

Incorrect or faulty wiring

Check wiring diagram and rewire correctly.

Thermostat setting too high

Lower thermostat setting below room temperature.

Compressor will not start

but condenser fan runs.

Faulty wiring or loose connections in compressor circuit

Check wiring and repair or replace.

Compressor motor burned out, seized, or internal

overload open

Determine cause. Replace compressor.

Defective run/start capacitor, overload, start relay

Determine cause and replace.

One leg of three-phase power dead

Replace fuse or reset circuit breaker. Determine cause.

Compressor cycles (other

than normally satisfying

thermostat)

Refrigerant overcharge or undercharge

Blow refrigerant, evacuate system, and recharge to nameplate.

Defective compressor

Replace and determine cause.

Insufficient line voltage

Determine cause and correct.

Blocked condenser

Determine cause and correct.

Defective run/start capacitor, overload, start relay,

or reset relay

Determine cause and replace.

Defective thermostat

Replace thermostat.

Faulty condenser fan motor or capacitor

Replace.

Restriction in refrigerant system

Locate restriction and remove.

Compressor operates

continuously.

Dirty air filter

Replace filter.

Unit undersized for load

Decrease load or increase unit size.

Thermostat set too low

Reset thermostat.

Low refrigerant charge

Locate leak, repair, and recharge.

Le'aking valves in compressor

Replace compressor.

Air in system.

Blow refrigerant, evacuate system, and recharge.

Condenser coil dirty or restricted

Clean coil or remove restriction.

Excessive head pressure

Dirty air filter

Replace filter.

Dirty condenser coil

Clean coil.

Refrigerant overcharged

Purge excess refrigerant.

Air in system

Blow refrigerant, evacuate system, and recharge.

Condenser air restricted or air short-cycling

Determine cause and correct.

Head pressure too low

Low refrigerant charge

Check for leaks, repair, and recharge.

Compressor valves leaking

Replace compressor.

Restriction in liquid tube

Remove restriction.

Excessive suction pressure

High heat load

Check for source and elim inate.

Compressor valves leaking

Replace compressor.

Refrigerant overcharged

Purge excess refrigerant.

Suction pressure too low

Dirty air filter

Replace filter.

Low refrigerant charge

Check for leaks, repair, and recharge.

Metering device or low side restricted

Remove source of restriction.

Insufficient evaporator airflow

Increase air quantity. Check filter— replace if necessary.

Temperature too low in conditioned area

Reset thermostat.

Outdoor ambient below 65°F

Install low-ambient kit.

Filter-drier restricted

Replace.

B. Lubrication

Fan and blower motors are prelubricated for 2 years of heavy

duty or 5 years of normal duty. When lubrication is neces

sary, send motor to an authorized motor repair shop.

C. Evaporator and Condenser Coils

CAUTION:

Be SSUJrfeiSp'hlectt^^^

OFF before cleaning coils.

The coils are easily cleaned when they are dry; therefore,

they should be checked and cleaned

before

each cooling

season. The coils should be inspected periodically during the

cooling season.

If the coils are coated with dirt or lint, they should be

vacuumed with a vacuum cleaner’s soft brush attachment.

Be careful not to bend the fins.

If the coils are coated with

oil or grease, they may be cleaned with a mild detergent and

water solution. Rinse coils with clear water. Be careful not

to splash water on motors, insulation, wiring, or filters.

D. Condensate Drain

The drain pan and condensate drain should be checked at the

same time the cooling coils are checked. Clean the drain pan

and condensate drain by removing any foreign matter from

the pan. Flush pan and drain tube with clear water. If the

drain tube is restricted, it can generally be cleared with

high-pressure water. If this does not work, try a “plumber’s

snake” or similar probe device.

E. Evaporator Blower

The blower should be inspected at least once each year. Re

move caked-on dirt from the blower wheel and housing with

brush; remove grease with mild solvent. Make sure blower is

centered in the blower housing.

F. Condenser Fan

The condenser fan should be kept free of all obstructions to

-14-

WARNING:

Do

:

nbt'i poke' .stitSss,

I

shhe^

i

¿ther

'i :i

;bliject::ihtp'frpvpl:^ihg!:i,fhhife^^

l i r e S u l t i ; ; ' ; ' : i i ' i V ; ' ;

i ; ' ’ i l i hi:';;

i ■V;i'' ':'iii i ¡'hi', ■;;

The required fan position is shown in Figure 3. Adjust fan

position by loosening setscrews and moving fan up or down.

G. Electrical Controls and Wiring

With power disconnected to unit, check all electrical connec

tions for tightness. Tighten all screws on connections. If any

smoky or burned connections are noticed, disassemble the

connection, clean all parts, strip wire, and reassemble prop

erly and securely. Electrical controls are difficult to check

without proper instrumentation; therefore, reconnect

electrical power to unit and observe unit through one com

plete operating cycle. If there are any discrepancies in the

operating cycle, contact your Dealer and request service.

H. Refrigerant Circuit

The refrigerant circuit is difficult to check for leaks without

proper equipment. Therefore, if low-cooling performance is

suspected, contact your local Dealer for service.

I. Cleaning the Heating Section

Soot, lint, or dirt on the .heating section components visible

in Figure 7 should be cleaned off before each heating season.

To insure dependable and efficient heating operation, the

heat exchanger should be checked by a qualified mainte

nance person before each heating season, and cleaned when

necessary. This checkout should not be attempted by anyone

not having the required expertise and equipment to do the

job properly. Checking and^r cleaning the heat exchanger

involves removing the unit top, disconnecting various motor

leads, and when completed, reinstalling the top properly to

maintain a proper seal. Contact your local Dealer for the re

quired periodic maintenance.