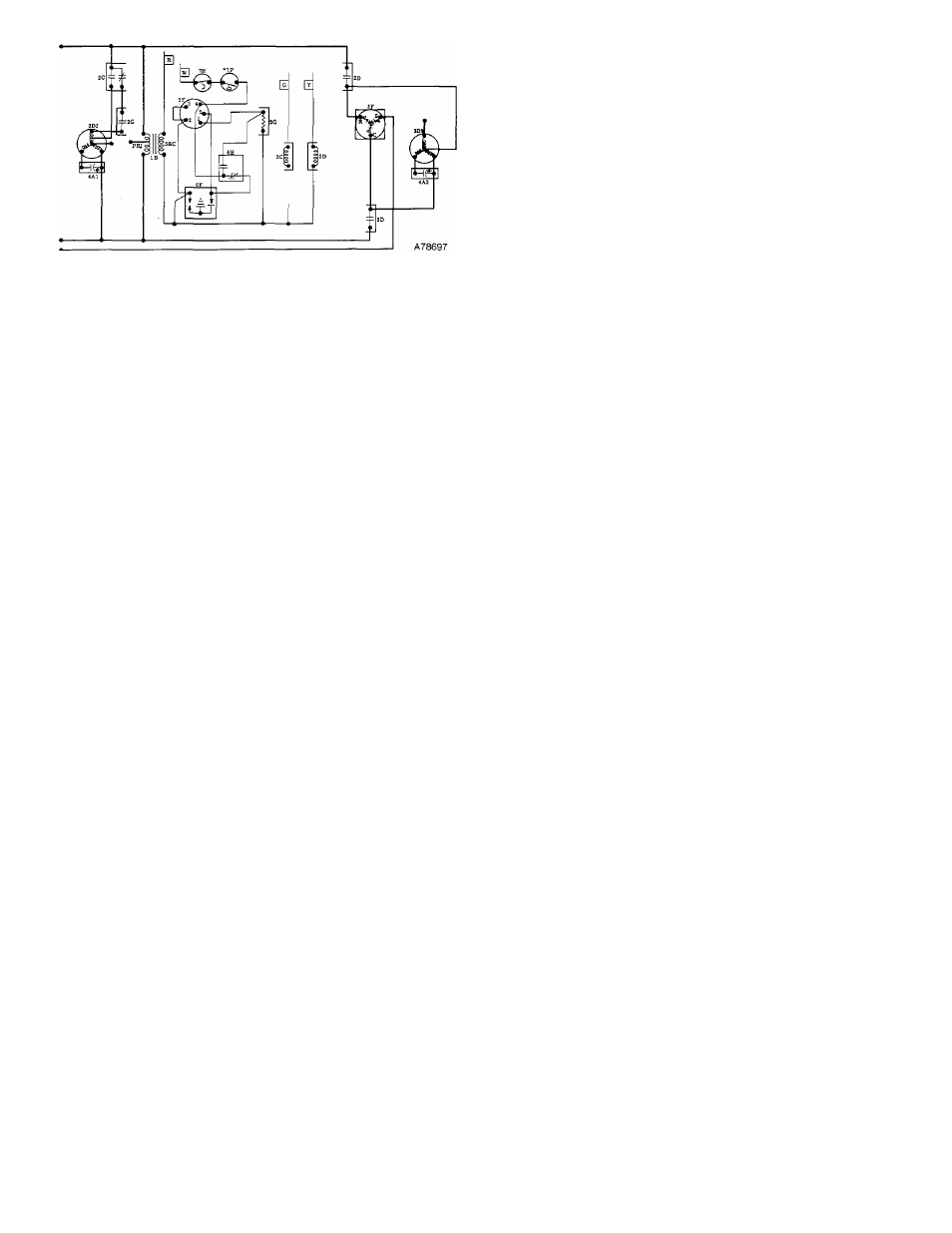

Figure 13—typical line-to-line wiring diagram, B. evaporator airflow & airflow adjustments, Determining evaporator airflow – Bryant 585B User Manual

Page 12: Airflow adjustments, C. checking unit operation, D. sequence of operation (cooling)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

LEGEND

1 B-Transformer

2

C-C

00

I Relay (SPOT)

2D-Contactor (N. O.)

2G-Heat Relay (821) (N. O.)

3D1-Condenser Motor

3D2-Evap Blower Motor

3F-Compressor

4A1 & 4A2-Run Capacitors

5F-Gas Valve

6F-Pilot Igniter

6H-Safety Pilot (Flame Sensing)

7H-Limit Switch (SPST)

*7P-Pressure Switch (N. O.)

“Pressure switch 7P required on propane units only.

Figure 13—Typical Line-to-Line Wiring Diagram

b. Leak-test unit.

c. Evacuate system.

CAUTION:

Charge unit with exact amount of refrigerant as

shown on unit rating plate.

d. Charge unit with proper type and amount of re

frigerant listed on unit rating plate. It is recom

mended that a volumetric charging cylinder or an

accurate scale be used.

4. Check to be sure all tools and loose parts have been re

moved.

5. Check to be sure all panels and covers are in place. Fol

lowing this initial inspection, unit may be started.

B. Evaporator Airflow & Airflow Adjustments

Model 585B units are equipped with a direct-drive blower

motor. Motor speeds have been factory-set for both heating

and cooling to deliver the proper airflow under normal static

pressures.

For cooling operation, the recommended evaporator airflow

is 350 to 450 ft^/min per 12,000 Btuh of cooling. For heating

operation, it is recommended that the airflow produce a tem

perature rise that falls within the range stamped on the unit

rating plate.

1. Determining Evaporator Airflow

Table VI shows air delivery at various temperature rises and

Table VII shows air delivery at various static pressures. Re

fer to these tables to determine the airflow.

NOTE:

Optional field-installed high-static blower packages

are available for sizes 036075 through 060150, single-phase

units. For air delivery applicable to these units, refer to the

air delivery data in Table VII for the equivalent size 3-phase

unit. (Three-phase units have factory-installed high-static

blowers.)

2. Airflow Adjustments

WARNING:

Disconnect all electrical power to the unit

before adjusting airflows.

Motor speed settings can be changed by changing motor lead

connections. The motor leads are color-coded as follows:

black = high speed

blue = medium speed

red = low speed

Sizes 018050, 024050, 036075, 036125, 042100, and 048125

single-phase units; and the 208/230-V, 3-phase version of

size 036075 have a 2-speed motor and do not have the blue

lead for medium speed.

All 460-V units operate on the same speed for both heating

and cooling. Size 036075 460-V units have a 2-speed motor.

Size 048125 and 060125 460-V units have a 3-speed motor.

For all 208- and 230-V units, the motor lead connected to the

heating relay 2G determines the heating speed, and the mo

tor lead connected to the cooling relay 2C determines the

cooling speed. See the unit wiring label. To change the heat

ing and/or cooling speed, connect the appropriate color-

coded motor lead to the appropriate relay. Be sure to tape

unused motor lead(s).

When the same speed is desired for both heating and cooling

for 208- and 230-V units, connect the appropriate color-

coded motor lead to either relay and connect a field-supplied

jumper between the two relays.

For all 460-V units, the single motor lead connection to the

blower relay 2A determines the single motor speed for both

heating and cooling. See unit wiring label. To change the

single motor speed, connect the appropriate color-coded mo

tor lead to the blower relay 2A. Be sure to tape unused motor

lead(s).

C. Checking Unit Operation

Perform the following steps to make certain the unit is

operating properly:

1. Place thermostat SYSTEM switch in COOL position;

place FAN switch in AUTO position; set thermostat set

ting below room temperature. Observe that compressor,

condenser fan motor, and blower motor are all running.

Observe that all motors stop when thermostat is

satisfied.

CAUTION:

Do mu tapid i'vi ’lo ci.inii)re.-; boTweeti cyclc>. Kapid-cycling can cause conijirossor damage. 2. Move thermostat fan switch to ON position. Observe that blower fan runs continuously with thermostat set above or below conditioned space temperature. D. Sequence of Operation (Cooling) The following sequence of operation pertains to Model 585B, 208- or 230-V, 3-phase units; sizes 036075, 036125, 042100, or 048125; however, the sequence of operation of all units is very similar. Refer to the line-to-line wiring diagram in Figure 13. NOTE: Although the actual unit wiring may vary slightly from that shown in Figure 13, the sequence of operation will not be affected. With the room thermostat SYSTEM switch in COOL and FAN switch in AUTO, the sequence of operation is as fol lows: When there is demand for cooling by the room thermostat, terminal R “makes” to terminals Y and G through the ther mostat. This circuit connects the compressor contactor coil 2D and cooling blower relay coil 2C across the 24-volt sec ondary of the transformer IB to energize the compressor contactor and blower relay. The contacts of the energized blower relay 2C close, completing the circuit through the single-phase blower motor 3D2, starting the motor in stantly. The contacts of the energized compressor contactor ■12-