D. base rails, E. condensate drain, Ii. venting – Bryant 585B User Manual

Page 3: 2% of

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

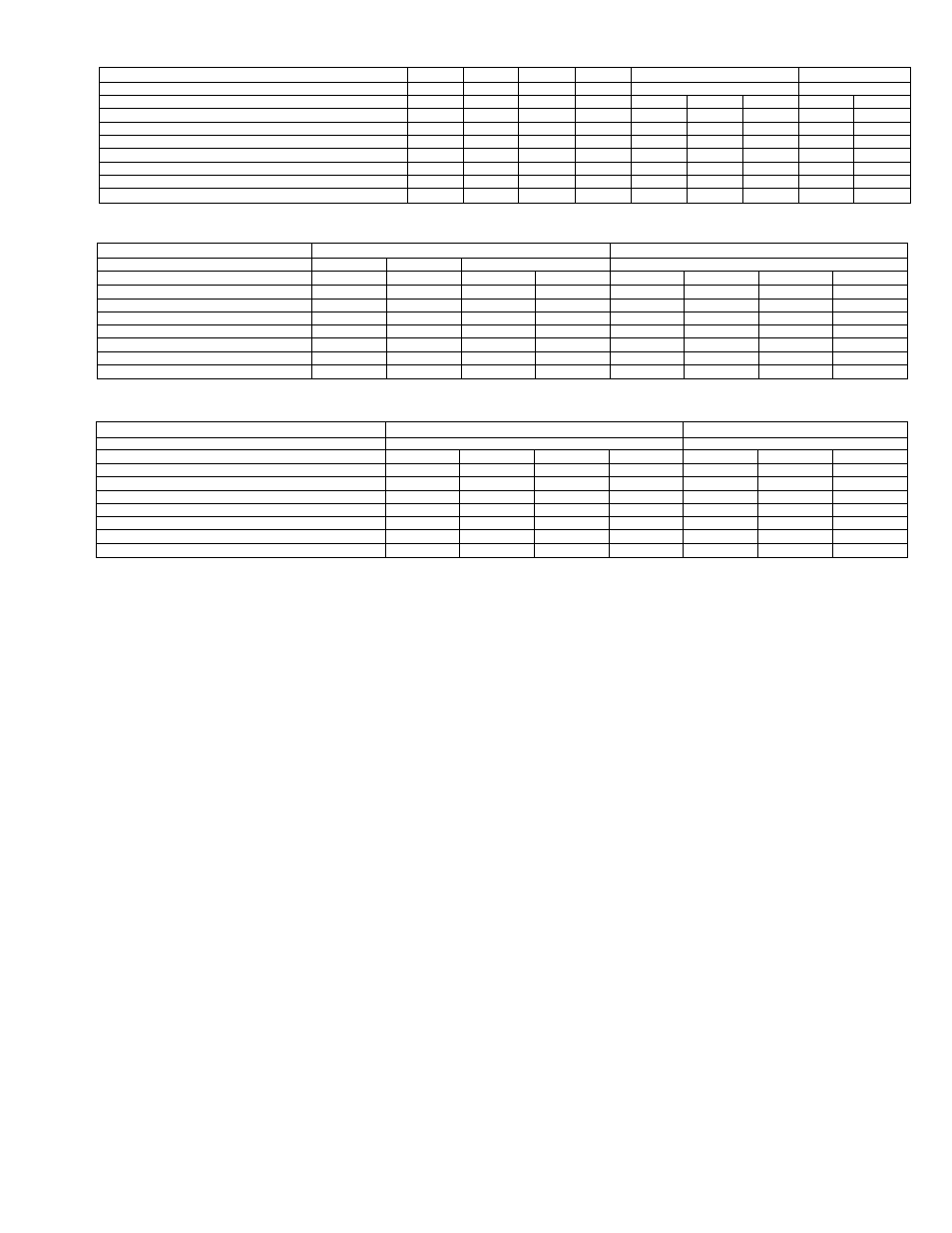

TABLE II-585B ELECTRICAL DATA (Sizes 018050 Thru 036125)

SIZE

018Q50

024050

024075

030075

036075

036125

SERIES

A

A

A

At or Bt

A

A

Unit Volts —Phase (60 Hz)

208/230-1

208-230-1

208-230-1

208-230-1

230-1

208-230-3

460-3

230-1

208/230-3

Operating Voltage Range

187-253

197-253

197-253

197-253

207-253

197-253

414-506

207-253

187-253

Total Unit Amps

14.2

17.2

17.6

22.6

25.6

21.6

10.4

23.8

21.36

Total Power Consumption (Watts)

2600

3200

3200

4150

5300

5300

5300

4750

4750

Max Branch Circuit Fuse Size (Amps)

25

30

30

40

50

30

20

45

30

Unit Ampacity for Wire Sizing

16.7

20.0

21.0

27.0

30.6

24.3

12.2

28.0

22.2

Min Wire Size (AWG) (60"C/75'O*

12/12

12/12

10/10

10/10

8/8

10/10

14/14

10/10

10/10

Max Wire Length (Ft) (60“C/75°O*

90/90

75/75

115/115

90/90

140/140

115/115

220/220

95/95

130/130

TABLE III-585B ELECTRICAL DATA (Sizes 042100 & 048125)

SIZE

042100

048125

SERIES

AT

BT

A

A

Unit Voits—Phase (60 Hz)

230-1

230-1

208-3

230-3

230-1

208-3

230-3

460-3

Operating VoPage Range

207-253

207-253

187-229

207-253

207-253

187-229

207-253

414-506

Total Unit Amps

27.92

30.92

24.6

21.7

31.8

26.56

23.7

12.4

Total Power Consumption (Watts)

5800

5800

5800

5800

6700

6700

6700

6700

Max Branch Circuit Fuse Size (Amps)

50

60

40

35

60

45

40

20

Unit Ampacity for Wire Sizing

33.0

37.0

28.3

25.0

38.7

30.8

27.5

14.4

Min Wire Size (AWG) (60”C/75”O*

8/8

8/8

10/10

10/10

8/8

8/8

10/10

14/14

■ Max Wire Length (Ft) (60"C/75’C)*

125/125

115/115

105/105

125/125

105/105

150/150

115/115

185/185

TABLE IV-585B ELECTRICAL DATA (Sizes 060125 & 060150)

SIZE

060125

060150

SERIES

A

A

Unit Volts—Phase (60 Hz)

230-1

208-3

230-3

460-3

230-1

208-3

230-3

Operating Voltage Range

207-253

187-229

207-253

414-506

207-253

187-229

207-253

Total Unit Amps

41.5

29.8

27.0

14.2

41.5

29.8

27.0

Total Power Consumption (Watts) -

8100

8100

8100

8100

8100

8100

8100

Max Branch Circuit Fuse Size (Amps)

80

50

50

25

80

50

50

Unit Ampacity for Wire Sizing

50.0

35.0

32.0

17.0

50.0

35.0

32.0

Min Wire Size (AWS) (60X/75X)*

6/6

8/8

8/8

12/12

6/6

8/8

8/8

Max Wire Length (Ft) (60°C/75’C)*

130/130

130/130

160/160

250/250

130/130

130/130

160/160

* Use copper wire only. Wire size is based on 60°C or 75°C copper conductor at 86°F (30°C) ambient temperature and ampacity shown in table. If other than 60°C or

75°C copper conductor is used, if ambient temperature is above 86°F, or if voltage drop of wire exceeds

2% of

unit rated voltage, determine wire size from

ampacity shown and the Mational Electrical Code. Wire lengths shown are measured one way along the wire path between unit and service panel for minimum

voltage drop.

tSeries designation may be A or B as determined by the compressor used at time of manufacture.

24 inches. Select a location where rain, ice, and snow will not

fall from an overhang and damage the unit top or fan blade,

or flood the unit.

There is no minimum clearance requirement for the bottom

of the unit; therefore, combustible materials can be used for

supports.

D. Base Rails

The base rails are easily removed for a lower profile installa

tion or a better fit to angle iron frames used in some rooftop

installations. To remove the base rails, simply remove the

screws on either end of the rails.

NOTE:

The base rails must not be removed when installing

the accessory unitized curb and plenum.

E. Condensate Drain

The unit is designed to dispose of condensate water through

a 3/4-inch FPT connection on the drain pan. See Figure 2 for

location. It is recommended that a trap be installed in the

condensate drain line to avoid improper drainage. See

Figure 5. The trap should be as close to the coil as possible.

Make sure that the top of the trap is at least 2 inches lower

than the drain pan connection to prevent the drainpan from

overflowing.

Prime the trap with water and check the condensate line for

leaks.

If the installation requires draining the condensate away

from the roof or the building, connect a minimum of 7/8-inch

OD copper tubing, 3/4-inch galvanized pipe, or 7/8-inch

plastic pipe, and pitch downward at a slope of at least 1 inch

in every 10 feet of horizontal run.

CAUTION:

Do not imdtTsizf conden.sate drain connection.

Consult local codes for additional restrictions and/or precau

tions.

II. VENTING

NOTE:

The vent cap assembly is shipped in the blower com

partment with sizes 018050 and 024050. Remove the blower

access door to locate the assembly. This assembly is shipped

in the control compartment with all other sizes. Remove the

control access door to locate the assembly. See Figure 2 for

the location of these access doors.

CAUTION:

The veniin g system has been designed to ensure

proper venting, fhe vent cap assembly niii.st be installed

only as indicated in this section of the unit Installation In

structions.

NOTE:

Screw holes in the vent stack extension and the vent

cap are not symmetrically located to ensure proper orienta

tion when installing these components.

Refer to Figure 6 and install the vent cap assembly as fol

lows:

1. Place gasket and vent stack extension through hole in

combustion air duct and orient screw holes in base of

vent stack extension with holes in unit top.

2. Secure gasket and vent stack extention to unit top with

screws provided.

3. Place vent cap onto vent stack extension and orient

screw holes in vent cap with holes in extension.

4. Secure vent cap in place with screws provided.

5. Form flat wire screen provided into circular shape

around protruding lip of combustion air duct.

6. Bend wire ends through holes of screen mesh to secure

screen in place.

-3-