G. sequence of operation (heating), H. limit and pressure switch operation, Viii. cooling startup and adjustments – Bryant 585B User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

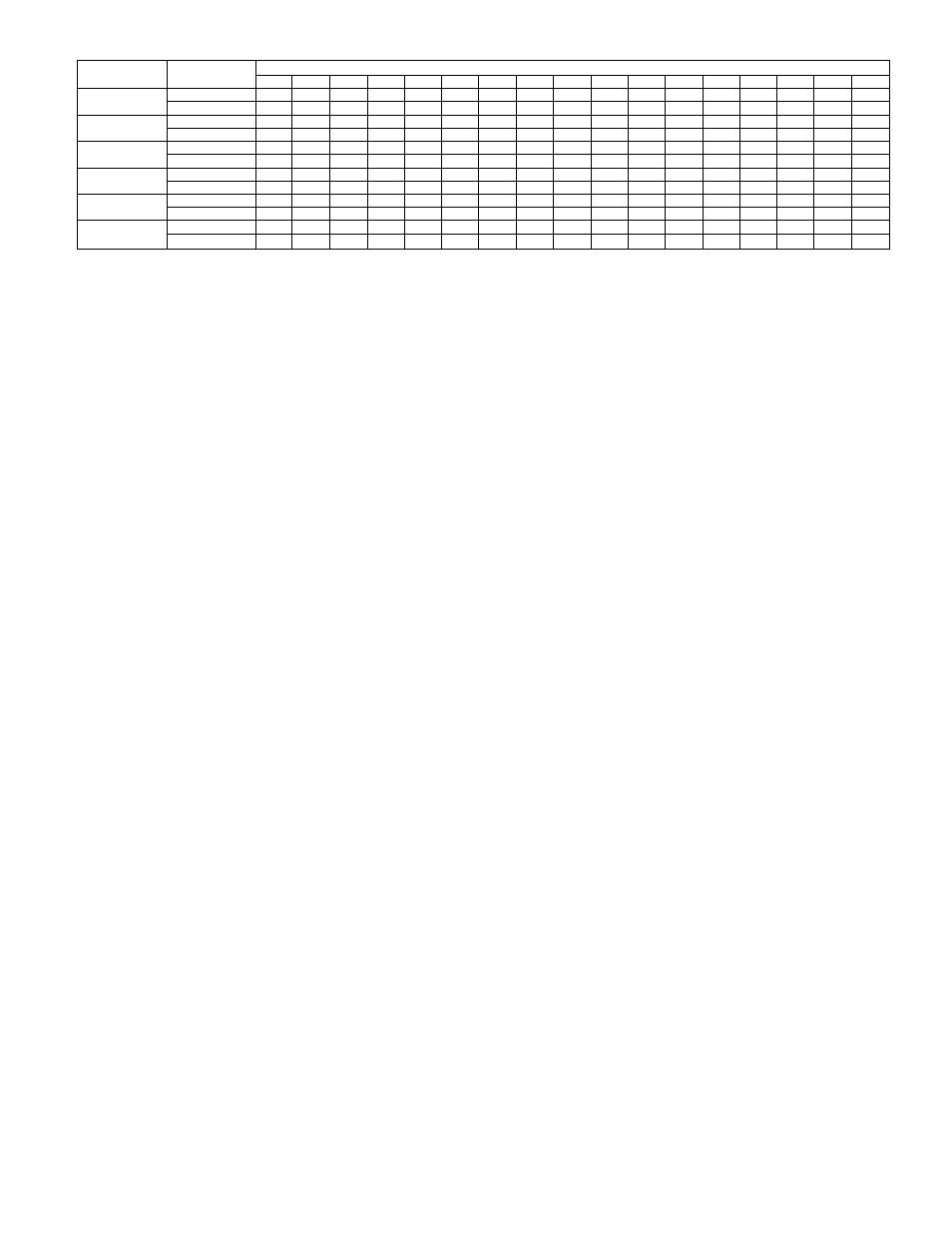

TABLE VI-AIR DELIVERY (FtVMin) AT INDICATED TEMPERATURE

RISE AND RATED HEATING INPUT

585B

Size

Heating

Input (Btuh)

Temperature Rise (°F)

35

37.5

40

42.5

45

47.5

50

52.5

55

57.5

60

62.5

65

67.5

70

72.5

75

018050

& 024050

40,000*

804

751

704

662

626

593

563

536

512

490

469

450

433

417

402

388

375

50,000

1032

963

903

850

802

760

722

688

657

628

602

578

556

535

516

498

481

024075, 030075,

& 036075(10)

60,000*

1206

1126

1056

993

938

889

844

804

768

734

704

676

650

626

603

582

563

75,000

1548

1444

1354

1275

1204

1140

1083

1032

985

942

903

867

833

802

774

747

722

036075(30)

60,000*

1206

1126

1056

993

938

889

844

804

768

734

704

676

650

626

603

582

563

75,000

1548

1444

1354

1275

1204

1140

1083

1032

985

942

903

867

833

802

774

747

722

042100

80,000*

1608

1501

1407

1325

1251

1185

1126

1072

1024

979

938

901

866

834

804

777

751

100,000

2063

1926

1806

1699

1605

1520

1444

1376

1313

1256

1204

1156

1111

1070

1032

996

963

036125, 048125,

& 060125

100,000*

2011

1877

1759

1656

1564

1481

1407

1340

1279

1224

1173

1126

1083

1043

1005

971

938

125,000

2579

2407

2257

2124

2006

1901

1806

1720

1641

1570

1505

1444

1389

1337

1290

1245

1204

060150

120,000*

2413

2252

2111

1987

1877

1778

1689

1608

1535

1469

1407

1351

1299

1251

1206

1165

1126

150,000

3095

2889

2708

2549

2407

2281

2167

2063

1970

1884

1806

1733

1667

1605

1548

1494

1444

*Rated heating input as manufactured with factory-installed burner orifices. Higher inputs shown for each size are the maximum rated

inputs using field-installed burner orifices.

NOTE: Shaded portions of the table are beyond the rated temperature rise range.

F. Airflow and Temperature Rise

The heating section is designed for operation within a tem

perature rise range of 35 to 70°F for units rated up to 75,000

Btuh input (except size 036075, 3-phase units), and within a

range of 45 to 75°F for units with inputs rated at 80,000

Btuh or higher.

Temperature rise is the difference of the air temperature in

the return duct and the air temperature in the discharge

duct at the unit.

Table VT shows the air delivery at various temperature rises

for both A.G.A.-certified input ratings for each size unit.

For heating operation, it is recommended that the airflow

.produces a temperature rise that falls within the range

stamped on the unit rating plate.

Refer to Section VIII, part B, of these instructions to deter

mine and adjust both the heating and cooling airflow.

G. Sequence of Operation (Heating)

The following sequence of operation pertains to model 585B,

208- or 230-V, 3-phase units; size 036075, 036125, 042100, or

048125; however, the sequence of operation of all other units

is very similar. Refer to the line-to-line wiring diagram in

Figure 13.

NOTE:

Although the actual unit wiring may vary slightly

from that shown in Figure 13, the sequence of operation will

not be affected.

With the room thermostat SYSTEM switch in HEAT posi

tion and FAN switch in AUTO position, the sequence of

operation is as follows:

Model 585B is equipped with the intermittent RELITE-type

pilot that does not have a standing flame, gas flow to the

pilot gas valve portion of the main gas valve 5F when the

pilot gas cock is open. The unit is now in a “standby” condi

tion, ready for a “call for heat” from the room thermostat.

When the room thermostat “calls for heat,” control lead R is

connected to control lead W through the room thermostat.

The 821 time-delay blower relay 2G becomes energized

through lead W. After a short delay, during which time the

following burner ignition sequence of operation is com

pleted, the blower relay contacts 2G close and the circuit to

the blower motor 3D2 is completed. This circuit energizes

the blower motor 3D2, starting the blower.

The circuit between R and W through the room thermostat

simultaneously energizes the pilot gas valve portion of the

main gas valve 5F and the pilot igniter 6F. The energized

pilot gas valve portion of the main gas valve 5F permits gas

flow to the pilot 6H.

NOTE:

The pilot gas valve portion of the main gas valve 5F

is a solenoid consisting of a “pick” and a “hold” coil. Both

coils must be energized to open the valve, but only the

“hold” coil must be energized to keep the pilot gas valve

open.

The energized pilot igniter 6F sends a high-voltage charge

to the pilot electrode 6H, producing a spark that ignites the

pilot flame. The pilot flame sensing monometal switch

proves the presence of the pilot flame. Approximately 40 to

60 seconds after the pilot flame is established, pilot 6H

switches its contacts, energizes the main gas valve 5F,

deenergizes the pilot igniter 6F, and deenergizes the “pick”

coil of the pilot solenoid. The main gas valve 5F is heat mo

tor operated; therefore, after approximately 10 seconds, the

main gas valve 5F opens permitting gas flow to the burners

where the gas is ignited by the pilot 6H.

When the room thermostat “call for heat” is satisfied, the

circuit between R and W through the room thermostat

breaks and gas flow through the main gas valve 5F is

stopped. The gas flow to pilot is also stopped and the pilot

flame goes out.

The 821 time-delay blower relay 2G is deenergized. There

will be a delay before the heating relay contacts 2G open.

When these contacts do open, the blower motor 3D2 is

deenergized.

The unit has now returned to a “standby” condition, waiting

for the next “call for heat” from the room thermostat.

H. Limit and Pressure Switch Operation

The furnace limit switch 7H (Figure 13) functions to shut off

the gas valve and main burner operation if the furnace leav

ing air temperature exceeds 175°F.

The pressure switch 7P (Figure 13) is only required when

the unit has been converted for propane gas operation. This

switch is part of the field-installed propane conversion kit.

See the conversion kit Installation Instructions for opera

tion of the pressure switch.

The normally closed furnace limit switch 7H completes the

control circuit through the W pigtail lead to the gas valve

5F. See Figure 13. Should the leaving air temperature rise to

175°F, the switch opens and the W control circuit is broken.

Any interruption in the control circuit through the W pig

tail lead to the gas valve instantly closes the gas valve and

stops gas flow to the burners and pilot.

The control circuit through the gas valve to the blower relay

2G is still closed and the blower motor 3D2 will continue to

run.

When the leaving air temperature drops to the limit switch

^ low-temperature setting, the switch closes, completing the

W control circuit. The electric-spark ignition system cycles

and the unit returns to normal heating operation.

VIII.

COOLING STARTUP AND ADJUSTMENTS

CAUTION:

Complete the stepsin Section VT before starting

unit.

Do not jumper anj" safety devices when operating unit.

-10-