Clutch rod adjustment, Note, Lubrication – Bolens 131-410A User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

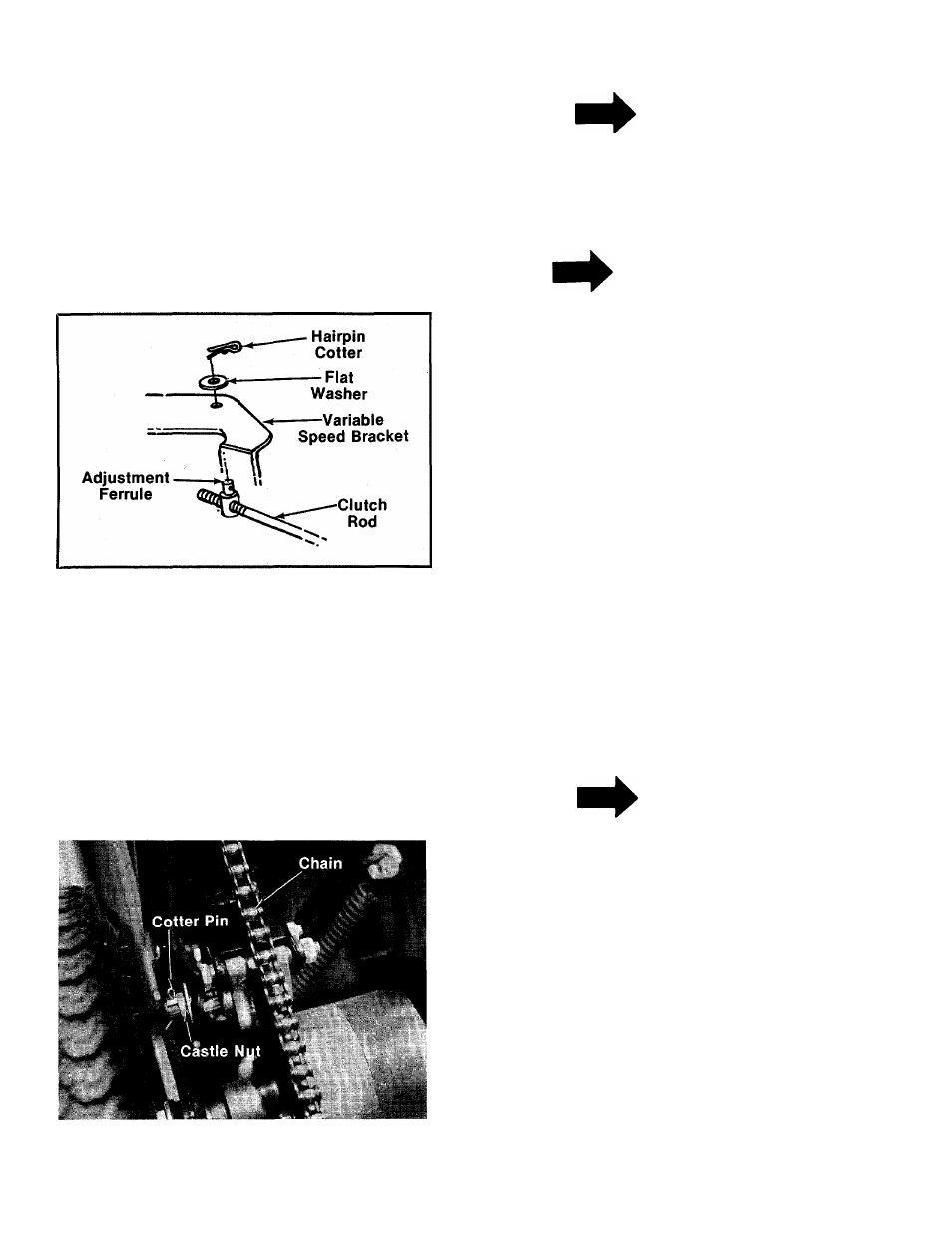

CLUTCH ROD ADJUSTMENT

1. With the engine off, reiease the clutch lock.

2. There should be 1/2" of space between the

end of slot and clutch lock button.

3. If there is not, remove the hairpin cotter from

the ferrule. Remove the flat washer and pull

the ferrule out of the variable speed pulley.

Thread ferrule in or out on the clutch rod as

necessary. Reassemble and check for correct

adjustment. See figures 27 and 28.

FIGURE 28.

BRAKE ADJUSTMENTS (See figure 29)

During normal operation of this machine, the

brakes are subject to wear and will require

periodic examination and adjustment.

The brake is located by the right rear wheel Inside

the frame.

To adjust the brake, remove the cotter pin. Tighten

the castle nut one-quarter turn. Replace the cotter

pin and test the brake.

NOTE

Deck was removed for photograph

ing.

LUBRICATION

1.

IMPORTANT

Always stop engine and disconnect

spark plug wire before cleaning,

lubricating or doing any kind of

work on lawn mower.

Engine. Maintain the engine oil according

the engine manual.

to

engine manual.

2. Bearings. The following bearings are oil im

pregnated and do not require lubrication.

However, their normal life can be extended by

lubricating them once a season with a light,

non-detergent oil. A 4 oz. plastic bottle of light

oil lubricant is available. Order part number

737-0170. Engine oil may also be used.

a. King Pin Bearings (total 4 bearings)

b. Rear Axle Bearings (total 3 bearings)

c. Front Wheel Bearings (total 4 bearings)

3. Throttle Control and Cable. Wipe oiled rag

along entire length of cable.

4. Chain. Periodically lubricate chain lightly with

oil. Wipe off excess oil, especially on the

sprocket. Do not get oil on the disc brake. See

figure 29.

FIGURE 29.

NOTE

Under extremely dusty conditions,

do not oil the chain.

5. Linkage. Oil all deck linkage and height ad

justment linkage.

6. Transmission. It is lubricated at the factory

and does not require checking. Lubricate with

4 oz. of Lubriplate No. 310 if disassembled.

7. Differential. It is lubricated at the factory and

does not require checking. Lubricate with 2

oz. of 450°F. High Temp, grease if disassem

bled. If ordered from the factory, use Part No.

737-0120.

8. Variable Speed Pulley. Apply dry lubricant be

tween the variable speed bracket and the

frame at least once a season.

16