6 electrical connections, 1 elearical junction box, 2 wiring – Generac Power Systems 004270-1 User Manual

Page 32: 3 generator ac connections, Electrical connections, Electrical junction box, Wiring, Generator ac connections

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTALLATION

Section 2 - Installation

QUIETPACT“ 75D Recreational Vehicle Generator

•

Use

exhaust

system

parts

recommended

by

Generac. Using unapproved exhaust mufflers and

exhaust system parts is the responsibility of the

person!s) installing such unauthorized parts.

•

Do not terminate the exhaust system under any

opening, window, or vent that can be opened or is

not permanently sealed from the vehicle interior.

•

Exhaust piping must be large enough to prevent

excessive back pressure on the generator engine.

•

Never tee the generator engine exhaust pipe into

the vehicle engine exhaust piping. This causes

excessive back pressure on the generator engine.

Also, water from one engine can damage the

other engine.

•

Plan

exhaust

system

installation

carefully.

Comply with all applicable codes, standards, and

regulations.

2.6

ELECTRICAL CONNECTIONS

Be sure to read Section 1.6 on Page 20.

The following general rules apply to electrical con

nections in a recreational vehicle:

• Qualified electricians who are familiar with applic

able

codes,

standards,

and

regulations

should

install electrical wiring.

•

The wiring should comply with codes, standards,

and

regulations.

The

National

Electrical

Code

(NFPA 70), and state and local codes apply.

• Switches and circuit breakers should be of a type

approved for use in recreational vehicles and must

be mounted and installed to prevent damage from

road shock.

•

Wiring must be of adequate size, have approved

insulative qualities, and be properly supported.

® Conduit and wire openings into the generator com

partment (if used) must be vapor-sealed to prevent

entry of flammable, explosive, or poisonous gases

into the vehicle.

2.6.1 ELEaRiCAL JUNCTION BOX

Install an approved, square electrical junction box

with a blank cover on the interior or exterior wall of

the area you plan to install the generator (NOT on the

generator). Route the generator's AC output leads

into this junction box through approved flexible con

duit. This is the point of first termination for genera

tor AC output leads.

•

2.6.2 WIRING

• Wiring should be of stranded copper to reduce the

chance that vibration may cause breakage.

• Wire gauge size should be large enough to handle

at least 115 percent of the installed generator's

rated maximum current.

30 Generac* Power Systems, Inc.

•

If neutral conductors are used, they must be the

same size as other leg wires.

• Route power supply conductors from generator AC

output leads T1 (red), T2 (white), T3 (black), and

the green ground wire through approved flexible

conduit to the electrical junction box on the com

partment wall.

If a flexible metal conduit is used between the gener

ator and the compartment junction box, the conduit

end that terminates at the compantment junction box

must be vapor-sealed. Flexible metal conduit is NOT

vapor-tight along its entire length.

•

From the junction box, route power supply wires

through approved conduit to either (a) double-pole,

double-throw transfer switch, or (b) approved isola

tion receptacle. Connecting to a transfer switch or

isolation receptacle must prevent vehicle electrical

circuits from being connected to two different power

supplies at the same time (such as, generator and

dockside power).

• Conductors must be rated 221° F (105° C) or must

be of a larger conductor size.

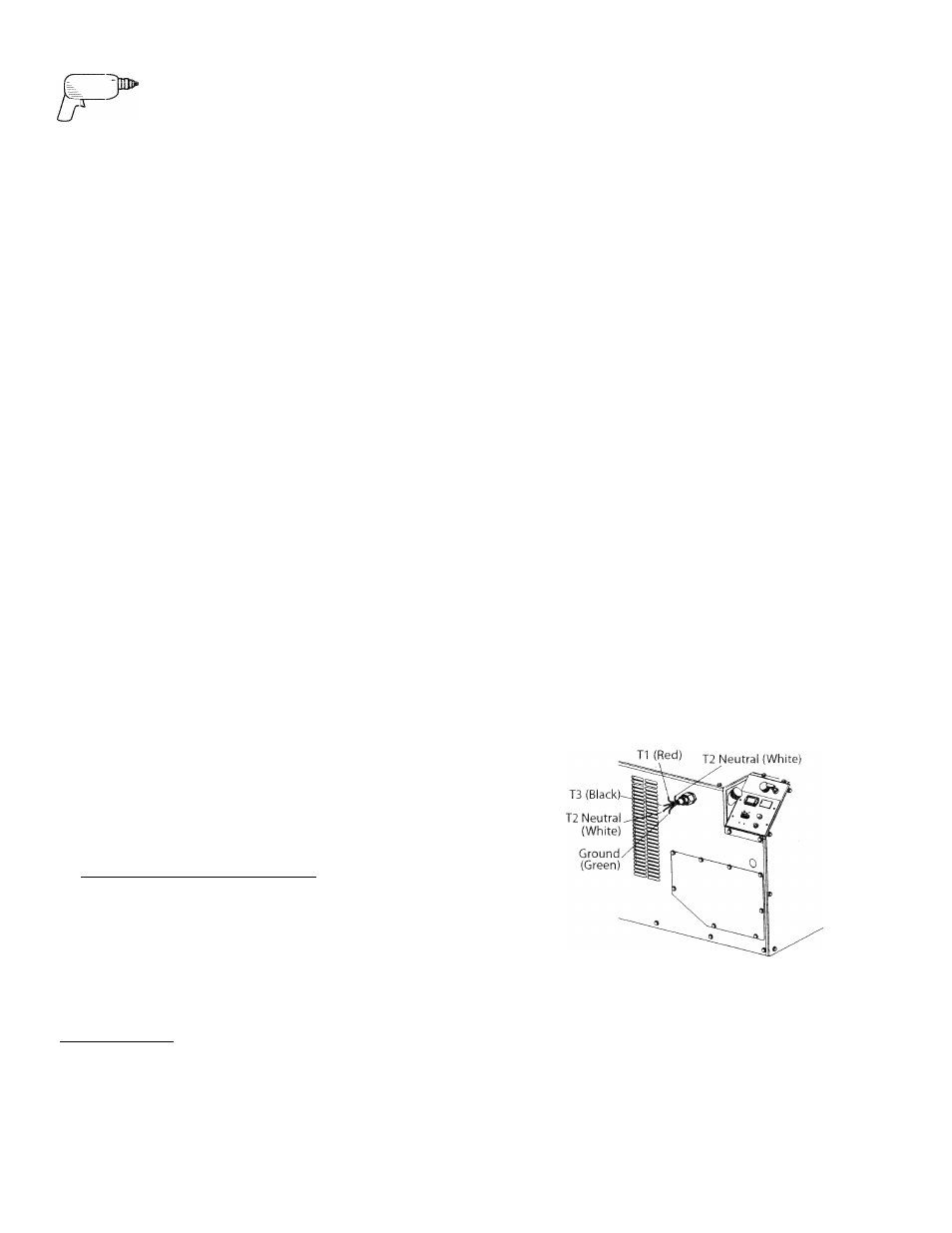

• 2.6.3 GENERATOR AC CONNECTIONS

Generator AC output leads T1 (red), T2 (white), and

T3 (black) come out of the generator, as shown in

Figure 2.14. Leads T1 (red) and T3 (black) are “hot,”

while T2 (white) is the grounded neutral lead. There

is also a green lead that connects to ground in the

junction box of the recreational vehicle.

Figure 2.14 - Generator AC Output Leads

QUIETPACT ™ generators use a four-position terminal

block to connect between stator power leads and vehi

cle load leads. This terminal block is accessible by

removing the access panel, shown in Figure 2.14. Units

are shipped from the factory connected for dual-voltage

(120/240 volts AC) output (See Figure 2.15). The stator

power windings are connected in series. Lead 11/1 lA

connects to T1 (Red), lead 44/44A connects to T3

(Black), while leads 22 and 33 are grounded and con

nect to T2 NEUTRAL (White). A "tie bar" connects the

two switch handles on line breaker CB1.