SINGER W4910 Euroflair User Manual

Page 40

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

aewing on Duttons, precision setting

Precision setting for buttonholing

The machine is set for sewing even and attractive

buttonholes in most commonly used fabrics. However,

some combinations of fabric, needle and thread may

cause some variations in the columns. If this is the case,

adjustment can be made by means of a screw located on

the top of the machine, under the handle.

If the left column is tighter than the right one, tighten

the screw slightly and try once more.

If the right column is tighter than the left one, loosen

the screw slightly.

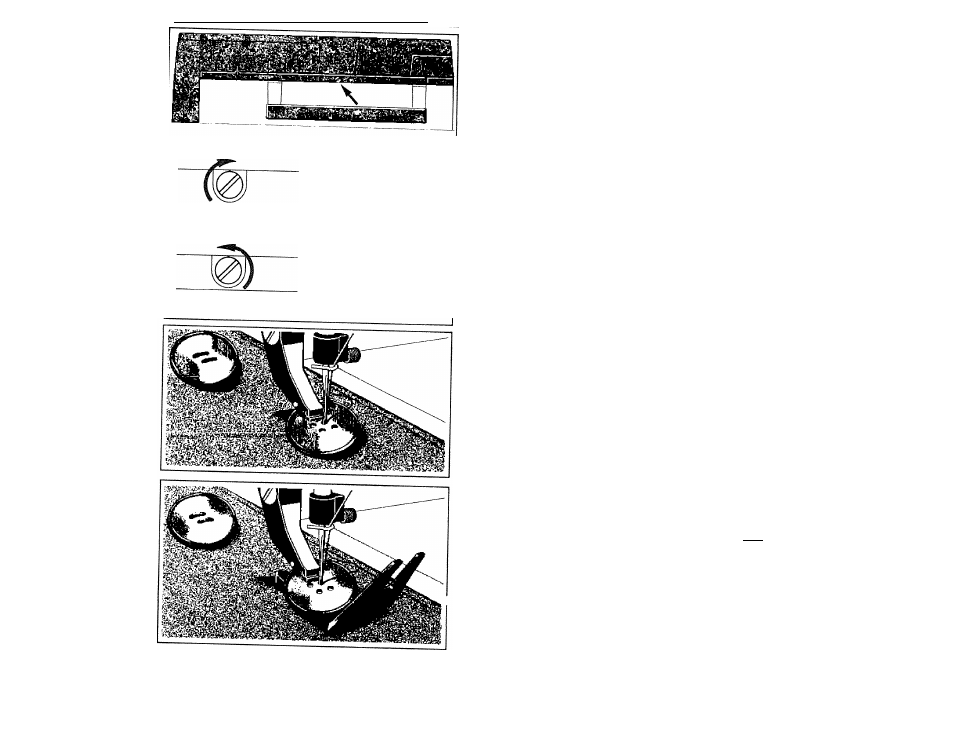

Sewing on buttons

Lower the feed dog. Remove the presser foot, put the

button in place and lower the presser bar. As most but

tons have 3-4 mm space between the holes, set the

stitch selector at the widest or intermediate zig-zag. Turn

the handwheel toward you and test carefully that the

needle enters the first hole and then the other hole.

Depress the foot control gently without moving the but

ton. Hold both thread ends behind the clamp and sew

five or six stitches. Move to the other holes and repeat.

Set the needle to straight stitch in the left needle position

and fasten the threads.

When sewing buttons on garments, a shank is often

required so that the button stands slightly away from the

fabric. Use the button reed for this purpose. Use the thin

end when sewing buttons on light fabrics, the thick end

for heavier fabrics. Fix the button with a stitch. Raise the

presser foot and place the button reed between the but

ton and the fabric. Lower the presser bar and sew on the

button.

Remove the button reed, pull the threads between the

button and the fabric, wind them a few times around the

shank and tie the ends.

38