Installing plain end blades – Sears 113.23615 User Manual

Page 27

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

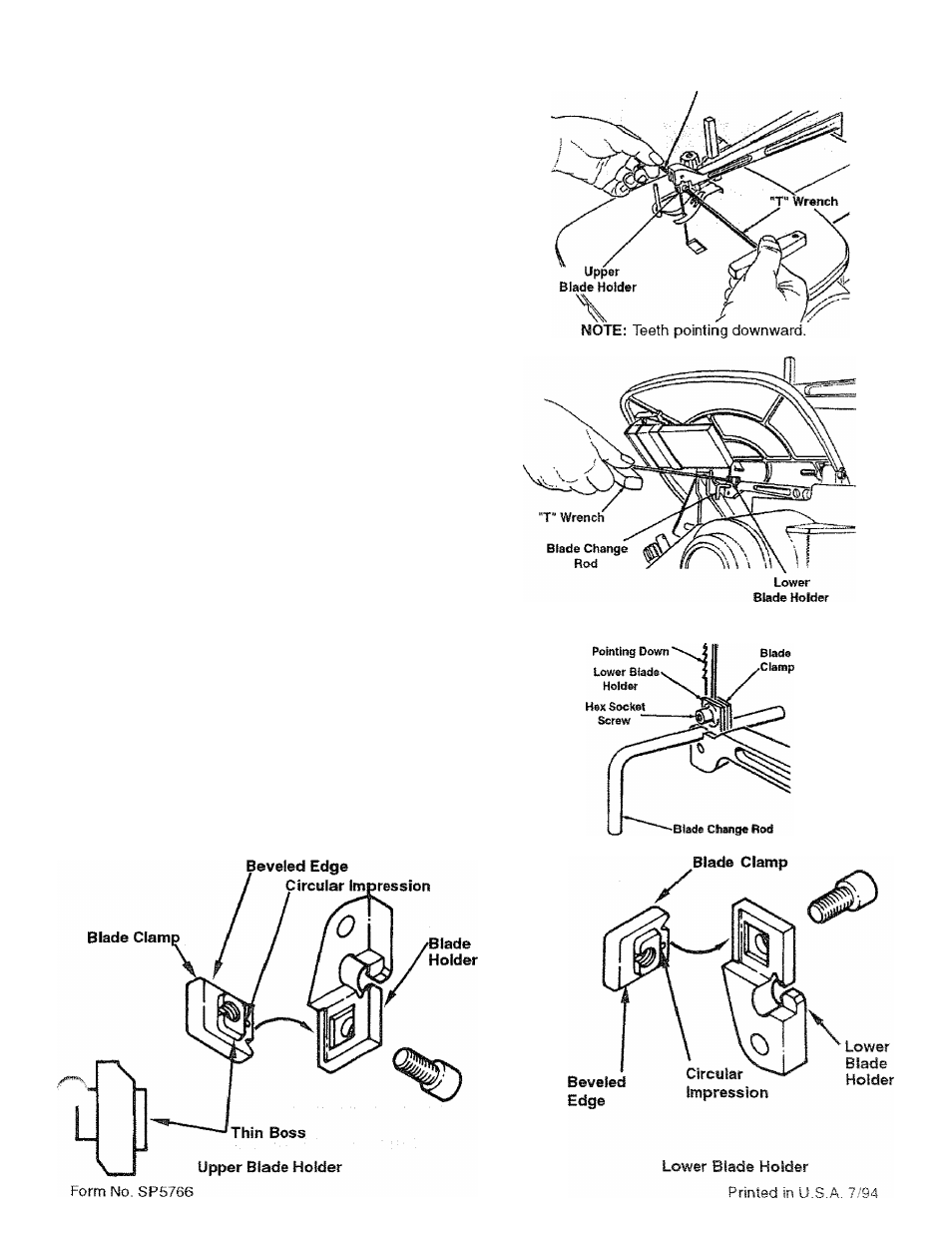

Installing Plain End Blades

NOTE: For plain end blades, the thin boss of the blade

needs to be positioned against the blade holder.

Plain End Blade Set Up; Insert the blade change rod

through the hole above the upper blade holder. Use

the “T' handle wrench to loosen the hex socket screw

and clamp trom the upper blade holder, install the

clamp so that the thin boss is against the blade holder,

and the beveled edge is in the corner of the blade

holder. The thin boss side of the blade clamp can be

identified by a circular impression placed on the sur

face.

2. Replace the hex socket screw.

3. Repeat this procedure on the lower blade holder.

4. install the blade through the hole in the table and into

the lower blade holder. The blade teeth should point

down. Position the blade end at the bottom of the blade

clamp and against the hex socket screw.

5. Tighten the hex socket screw, using the “T’ wrench,

while holding the blade change rod in position.

6. Use the same procedure to install the blade into the

upper blade holder. Before tightening the socket hex

screw, adjust the position ot the upper blade holder by

turning the blade tension knob until the end of the

blade is near the top of the blade holder.

7. Remove the “T’ wrench and the blade change rod from

^^the blade holder.

Tighten the blade tension knob clockw/ise

until the blade is tensioned. The number of turns will

be approximately two full turns. This will vary depend

ing on blade thickness and blade type.

9. Make sure the blade is properly installed. Before apply

ing power, rotate the motor shaft by hand using a

screwdriver in the motor shaft as shown on the previ

ous page.

Blade Change Rod

WARNING: To avoid injury from thrown objects,

remove the blade change rod and all tools from the

saw.

Note: Teeth