Removing pin end blades, Installing pin end blades, Removing and installing blades – Sears 113.23615 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Removing and Installing Blades

WARNING: To avoid injury from accidental starting,

always turn switch “OFF" and unplug power cord

from outlet before removing or replacing the blade.

NOTE: Saw comes set up for pin end blades. !f you are

going to use plain end blades, refer to the instructions

under “installing Plain End Blades" below.

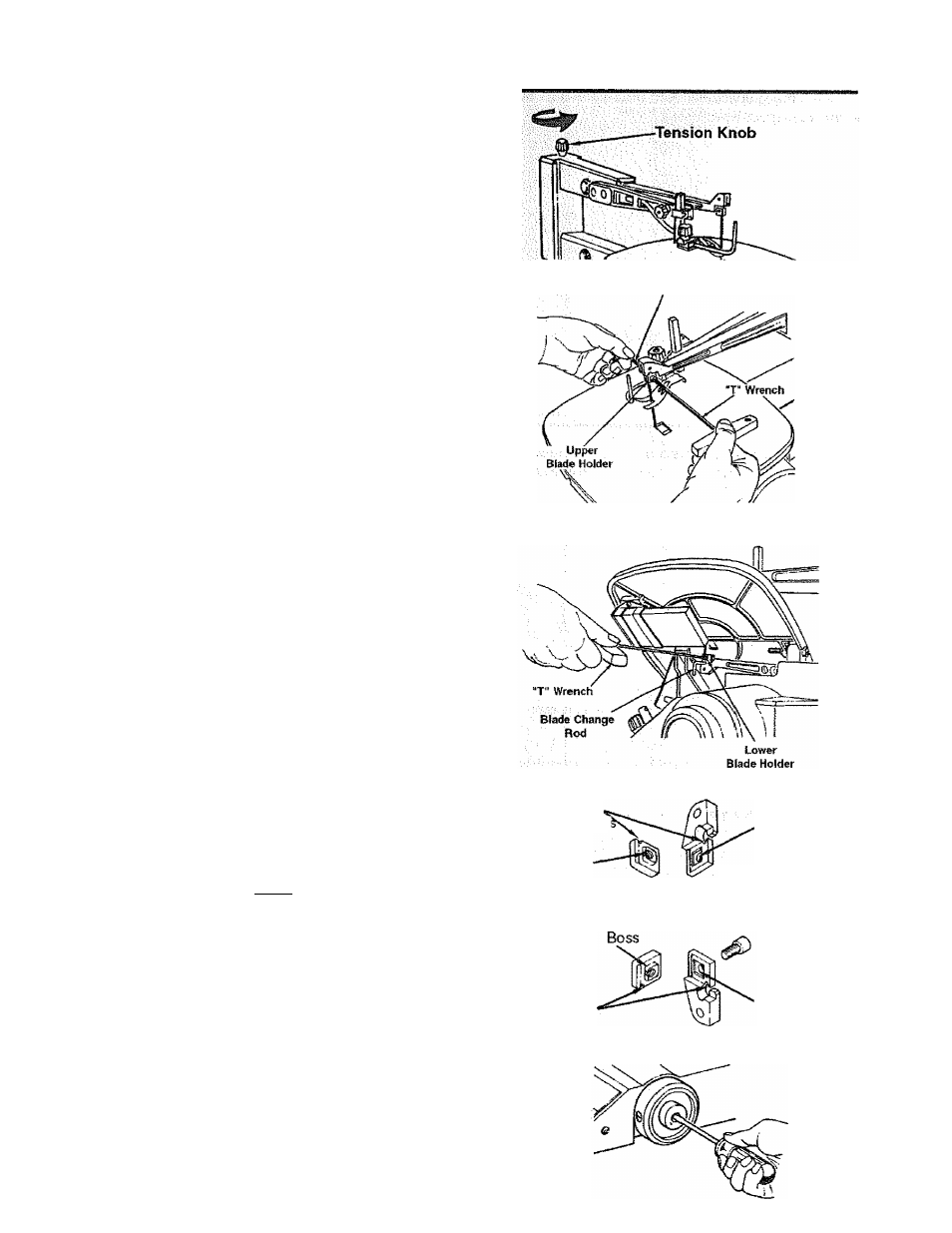

Removing Pin End Blades

1. Unplug power cord from outlet and check that switch is

off.

2. Loosen tension on blade by turning tension knob coun

terclockwise

about three full turns,

3. Remove blads from thé lower blade holder by pushing

down on the upper arm, releasing thé blade/pin from

the lower blade holder. Remove blade from the upper

blade holder by slightly lifting up on the blade and pull

ing forward,

................. ...........................

Blade Change Red

Installing Pin End Blades

NOTE: The saw comes from the factory already set up

for pin end blades.

....... ......

1. Pin End Blade Set Up; Insert the blade change rod

thrdugh the hole above the upper blade holder. Use

the “T” handle wrench to loosen the hex socket screw

and clamp from the upper blade hdlde Install the

clamp so that the boss goes into the recess in the

blade holder. The ‘V’ notches must line up.

2. Tighten the hex socket screw.

3. Repeat this procedure on the lower blade holder.

4. Check that the tension knob is loose.

5. Install the blade through the insert opening with the

teeth pointing down. Engage the pin into the “V" notch

of the lower blade holder.

6. Pull up on the blade and engage the upper pin in the

notch of the upper blade holder.

7. Carefully tighten the blade tension by turning the ten

sion knob clockwise

until you feel the slack in

the blade is removed.

^

8. Check to see that the pins are properly located in the

slots. Turn the tension knob an additional two full turns

clockwise. This amount of blade tension should do

well for rnostj cutting opetations and blades. The num

ber of turns will be approximately two full turns. This

will vary dependihg dii hidde thickness and blade type.

9. Make sure the blade is properly instailed. Before apply^

ing power, rotate the motor shaft by hand using a

screwdriver in the motor shaft slot as shown.

WARNING: To avoid injury from thrown objects,

remove the blade change rod and ail tools from the

saw.

NOTE: Teeth pointing downward.

i; TV

Note he:

Boss

Recess

Blade Clamp Upper Blade Holder

"V"

Notches

'Recess

Blade Clamp Lower Blade Holder

10