Warning – Sears 9MPD125L20B1 User Manual

Page 47

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Tcibltí 14

Concentric Termination Kit

NAHA001CV & NAHA002CV Venting

Table for N9MP2 Models

50,000 & 80,000 Btuh Furnaces

NAHA002CV - 35' &

(4) 90° elbows with T PVC pipe or

NAHA001CV - 65' &

(4) 90° elbows with 3" PVC pipe

75,000 Btuh Furnaces

NAHA002CV - 20' &

(2)

90°

elbows with 2" PVC pipe or

NAHA002CV -

35'

& (4) 90°

elbows with 2" PVC pipe &

Long Vent Kit (See Tech. Manual) or

NAHA001CV -

65'

& (4) 90°

elbows with 3

"

PVC pipe

100,000 Btuh Furnace

NAHA001CV - 35' & (4) 90°

elbows with

3

" PVC pipe or

NAHA001CV - 65' & (4) 90°

elbows with

3 "

PVC pipe &

Long Vent Kit (See Tech. Manual)

125,000 Btuh Furnace

NAHA001CV - 35' & (4) 90° elbows with 3 " PVC pipe

1. Do not include the field supplied 45° elbow in the total elbow

count.

2. If more than four elbows are required, reduce the length of

both the inlet and the exhaust pipes five feet for each

additional elbow used.

3. Elbows are DWV long radius type for 2" and 3” vents.

NOTE: Feet of pipe is whichever pipe run is the longest, either

inlet or outlet side.

If assembly needs to be extended to meet height or side wall thick

ness requirement, the two pipes supplied in the kit may be re

placed by using the same diameter solid, single (no coupling

connections) field supplied SDR-26 PVC (ASTM D2241) pipes.

Do not extend dimension D more than 60". (See Figure 47)

Do not use field supplied couplings to extend the pipes.

Airflow restriction will occur and the furnace pressure switch

may cause intermittent operation.

5. Partially assemble the concentric vent termination kit.

Clean and cement the parts using the procedures for Join

ing Pipe and Fittings section of the manual. A) Cement the Y

Concentric fitting to the 4" diameter kit pipe. (See

Figure 48) B) Cement the 3' rain cap to the

2

V

2

' diameter

kit part. (See Figure 48) NOTE: A field supplied stainless

steel screw may be used to secure the rain cap to the pipe

instead of cementing when field disassembly is desired for

cleaning (See Figure 48)

Figure: 48

Rain Cap to Vent Pipe Assembly

Drill clearance hole in

cap and pilot hole in \

rain

rent pipe.

S

25-22-02 (F

tainless steel screw

ield supplied)

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in death,

personal injury and/or property damage.

When using the alternate screw assembly method,

drill a clearance hole in the rain cap and a pilot hole

in the vent pipe for the screw size being used.

Failure to drill adequate holes may cause cracking

of the PVC components, allowing fiue gases to be

recirculated.

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in death,

personai injury and/or property damage.

Do not operate the furnace with the rain cap

removed as recirulation of the flue gases may

occur. Water may also collect inside the larger

combustion air pipe and flow to the burner

enclosure.

6

.

Install the Y concentric fitting and the pipe assemblythrough

the structure's hole. For vertical termination, install the parts

through the field supplied roof boot/flashing. NOTE: Do not

allow insulation or other materials to accumulate inside the

pipe assembly when installing through the structure's hole.

7.

Secure the assembly to the structure as shown in Figure 46

or Figure 50 using field supplied metal strapping or equiva

lent material.

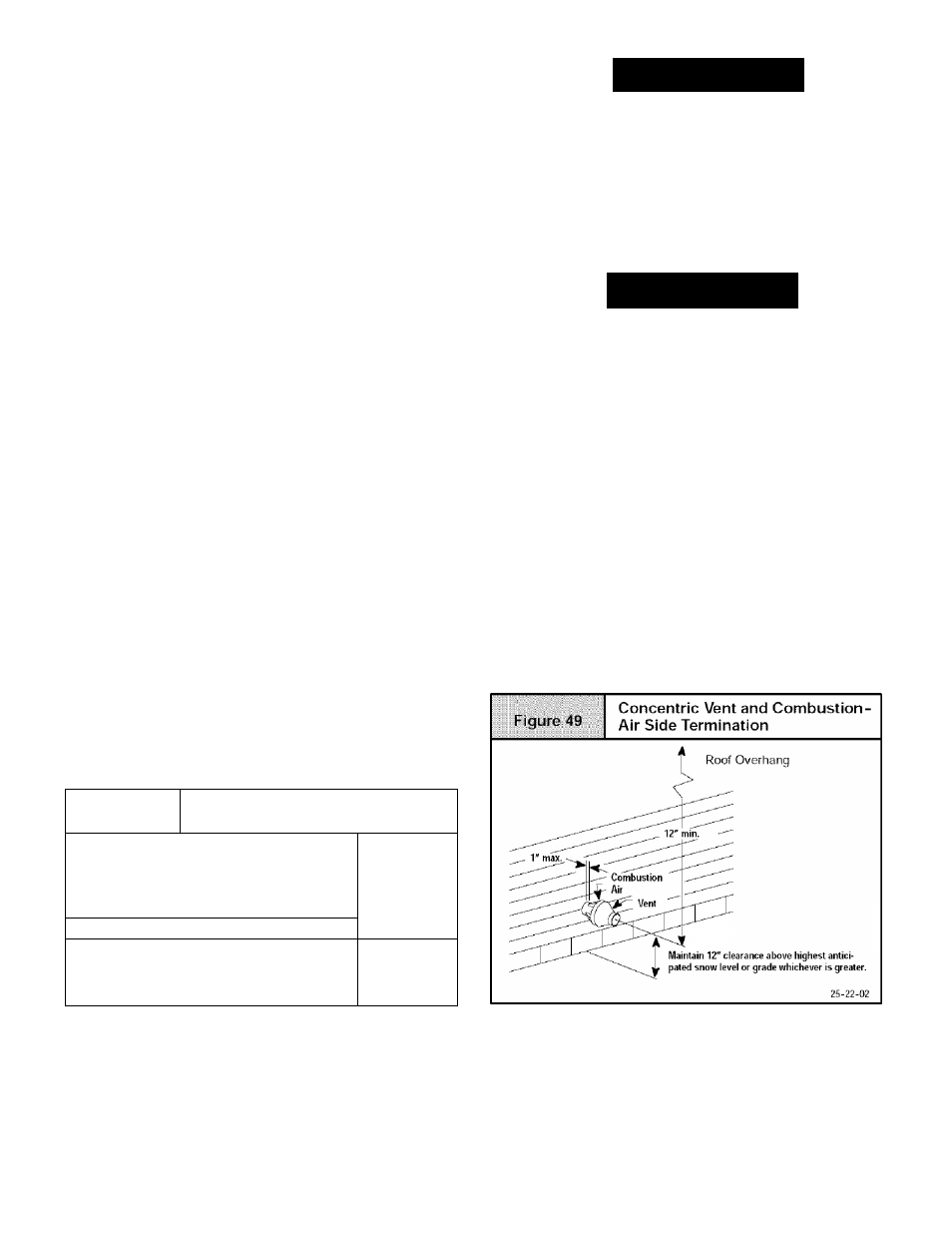

NOTE: Ensure the termination height is above the roof sur

face or anticipated snow level as shown in Figure 46 for

vertical termination. Ensure the termination location clear

ance dimensions are as shown in Figure 49 and Figure 50

for horizontal termination.

440 01 1020 04

□3