Filter installation using optional filter rack, Addition of air conditioning, Combustible floor installation – Sears 9MPD125L20B1 User Manual

Page 36: Fire hazard, Subbase for combustible floor, Warning, Caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

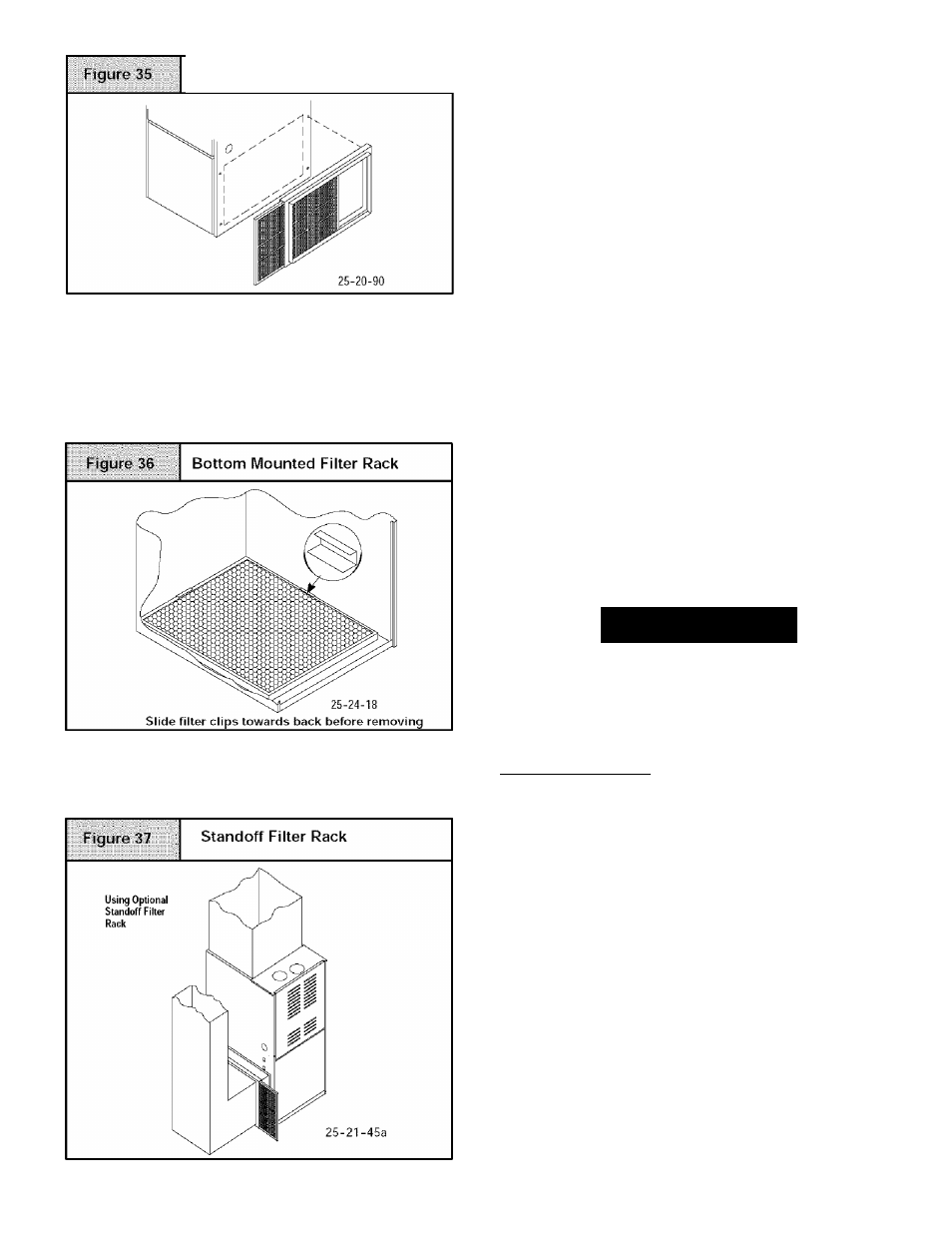

Side Mounted Filter Rack

Filter Installation using Optional Filter Rack

When installing or removing a bottom mounted filter, slide the two

side filter clips to the back of the furnace BEFORE installing or re

moving. This will allow the filter to clear the front raised edge of the

furnace. Insert filter into side clips first and push filter back until it is

fully engaged into back clip. When filter is in place, slide clips back

into place midway on filter as shown in Figure 36.

Refer to Figure 37 and for guidelines to install filters. Furnaces

which require larger filter media and have limited clearances on

one side of furnace, require a standoff filter rack, see Figure 37,

available from your distributor.

CAUTION

If filters are only suitable for heating application, advise

homeowner that filter size may need to be increased if air

conditioning is added.

Addition Of Air Conditioning

When a refrigeration coil is used in conjunction with this unit, it

must be installed on the discharge side of the unit to avoid con

densation on the heat exchanger. The coil installation instructions

must be consulted for proper coil location and installation proce

dures. With a parallel flow arrangement, dampers must be

installed to prevent chilled air from entering the furnace. If manual

ly operated dampers are used, they must be equipped with a

means to prevent operation of either unit unless the damper is in

full heat or full cool position.

A3" clearance is required on the right side of the furnace in orderto

run the condensate drain line. Copper, iron or plastic tubing may be

used for the condensate drain line.

Downflow Furnace Installation

Non-Combustible Floor Installation

Fabricate a plenum to the dimensions given in Table 11, for the fur

nace outlet. Plenum should be flanged, approximately

^/4

" for sup

port.

Note: The three(3) screws in the top panel of the furnace next to

the duct flange MUST be removed to provide serviceability of the

primary heat exchangers in the downflow installation

1.

Position plenum through the floor and set the furnace over

the opening in the floor. If necessary, grout around the base

to seal air leaks between the base and the floor.

Combustible Floor Installation

WARNING

FIRE HAZARD

Failure to install unit on noncombustible subbase

could result in death, personal injury and/or

property damage.

Place furnace on noncombustible subbase on

downflow applications, uniess installing on non-

combustibie flooring.

Subbase for Combustible Floor

NOTE: The three(3) screws in the top panel of the furnace next to

the duct flange MUST be removed to provide serviceability of the

primary heat exchangers in the downflow installation

Note: When using the subbase for combustible floors, the dis

charge air duct flanges on the furnace MUST be broken down to

provide proper fit up to the subbase. Use duct pliers to bend the

duct flanges flat onto the furnace casing. DO NOT bend the duct

flanges inward (toward the heat exchangers) as air flow restric

tions may occur.

The Subbase for Combustible Floors MUST be used when a

downflow furnace is set on a combustible floor, even when the fur

nace is installed on a coil box.

1.

Cut the opening in the floor according to Table 11. The hole

in the floor must be cut to the dimensions listed in Table 11

since the base is equipped with locating tabs that center the

base over the opening.

The opening in the base is

1V4"

shorter and

1V0"

narrower than

the recommended size of the opening in the floor. This is done to

maintain clearance between the floor and the plenum.

2.

Fabricate the plenum to the dimensions given in Table 11.

Note that the dimensions given are outside dimensions.

[3^

440

01 1020 04