General derating rules, High altitude air pressure switch, Changing orifices for high altitude – Sears 9MPD125L20B1 User Manual

Page 31: Natural gas input rating check, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 9

LPG or PROPANE GAS MANIFOLD PRESSURE (" w

.

c

.)

FOR THE 80,000 BTUH MODELS

HEATING VALUE

at ALTITUDE

BTU/CU. FT.

MEAN ELEVATION FEET ABOVE SEA LEVEL

0

to

2000

2001

to

3000

3001 to

4000

4001 to

5000

5001 to

6000

6001 to

7000

7001 to

8000

2500

10.0

8,9

8.4

10,0

10.0

10,0

10,0

Orifice Size

#55

#55

#55

шпштггт

тпжжат

Ü

5

G

mnwëÈvmm

NOTE: Propane data is based on 1.53 specific gravity. For fuels with different specific gravity consult the National Fuel Gas Code ANSI Z223.1 -2002/NFPA

54-2002 or National Standard Of Canada, Natural Gas And Propane Installation Code CSA B149.1 -00.

NOTE: The derating of these furnaces at 2% (Natural Gas) and

4% (Propane Gas) has been tested and design-certified by CSA.

General Derating Rules

These furnaces may be used at full input rating when

installed at altitudes up to 2,000’. When installed above

2,000', the input must be decreased 2% (natural) or 4% (LP)

for each 1000’ above sea level. See Table 10 for required

high altitude input rate.

Tablo 10

High Altitude Input Rate =

Nameplate Sea Level Input Rate x (Multiplier)

Elevation

High Altitude Multiplier

Natural Gas

LP Gas

2001

'

- 3000'

0.95

0.90

3001 ' - 4000'

0.93

0.86

4001 ' - 5000'

0.91

0.82

5001 ' - 6000'

0.89

0.78

6001 ' - 7000'

0.87

0.74

7001 ' - 8000'

0.85

0.70

* Based on mid-range of elevation.

2.

For operation with natural gas at altitudes above 2,000’, ori

fice change and/or manifold pressure adjustments may be

required for the gas supplied. First consult your local gas

supplier, then refer to Table 6 (50,000, 75,000, 100,000

and 125,000 BTUH models) or Table 8 (80,000 BTUH mod

els) for required pressure change and/or orifice change for

high altitudes.

3.

For operation with LP gas, gas orifices MUST be changed

and manifold pressure MUST be

maintained

as per Table 7

(50,000, 75,000,100,000 and 125,000 BTUH models) or

Table 9 (80,000 BTUH models). Orifices can be ordered

through our distributor. (See Figure 29)

4.

In cases where Table 6, Table 7, Table 8 or Table 9 is not

applicable, eg. alternate input rate application, refer to

Table 10 for required high altitude input rate.

High Altitude Air Pressure Switch

Altitudes over 4,000’ may require a different air pressure switch

than the one installed at the factory. Check parts list for pressure

switch and consult your distributor for part number and availability.

In Canada, provincial codes may govern installation of switch.

Check with governing authorities.

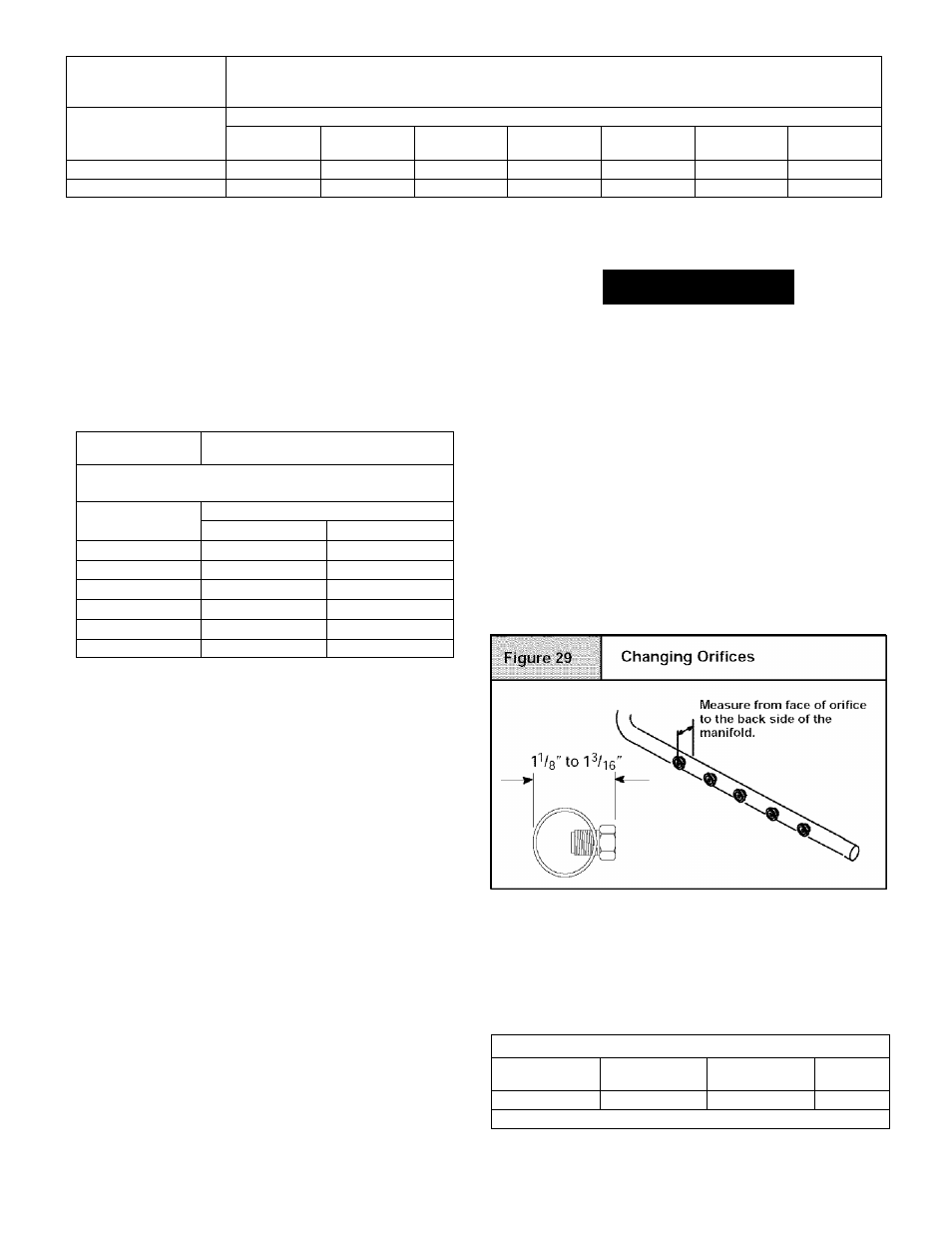

Changing Orifices for High Altitude

WARNING

ELECTRICAL

SHOCK,

FIRE

OR

EXPLOSION

HAZARD

Failure to properly install orifices could result in

death, personal injury and/or property damage.

Turn OFF electric power (at disconnect) and gas

supply (at manual valve in gas line) when instailing

orifices. Installation of orifices requires a quaiified

service technician.

NOTE: Main burner orifices can be changed for high altitudes.

1.

Disconnect gas line from gas valve.

2.

Remove manifold from furnace.

3.

Remove the orifices from the manifold and replace them

with properly sized orifices.

4.

Tighten orifices so it is seated and gas tight. (See

Figure 29)

5.

Reinstall manifold. Ensure burners do NOT bind on new ori

fices.

Natural Gas Input Rating Check

NOTE: The gas meter can be used to measure input to furnace.

Rating is based on a natural gas BTU content of 1,000 BTU's per

cubic meter. Check with gas supplier for actual BTU content.

1.

Make sure burner compartment door is in place before per

forming the following steps.

2.

Turn OFF gas supply to all appliances and start furnace.

Example

Natural Gas

No.of Seconds

Time Per Cubic

BTU Per

BTU Content

Per Hour

Foot in Seconds

Hour

1,000

3,600

48

75,000

1,000x 3,600-48 = 75,000 BTUH

440

01 1020 04

Ш1