Carrier 38HQ User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

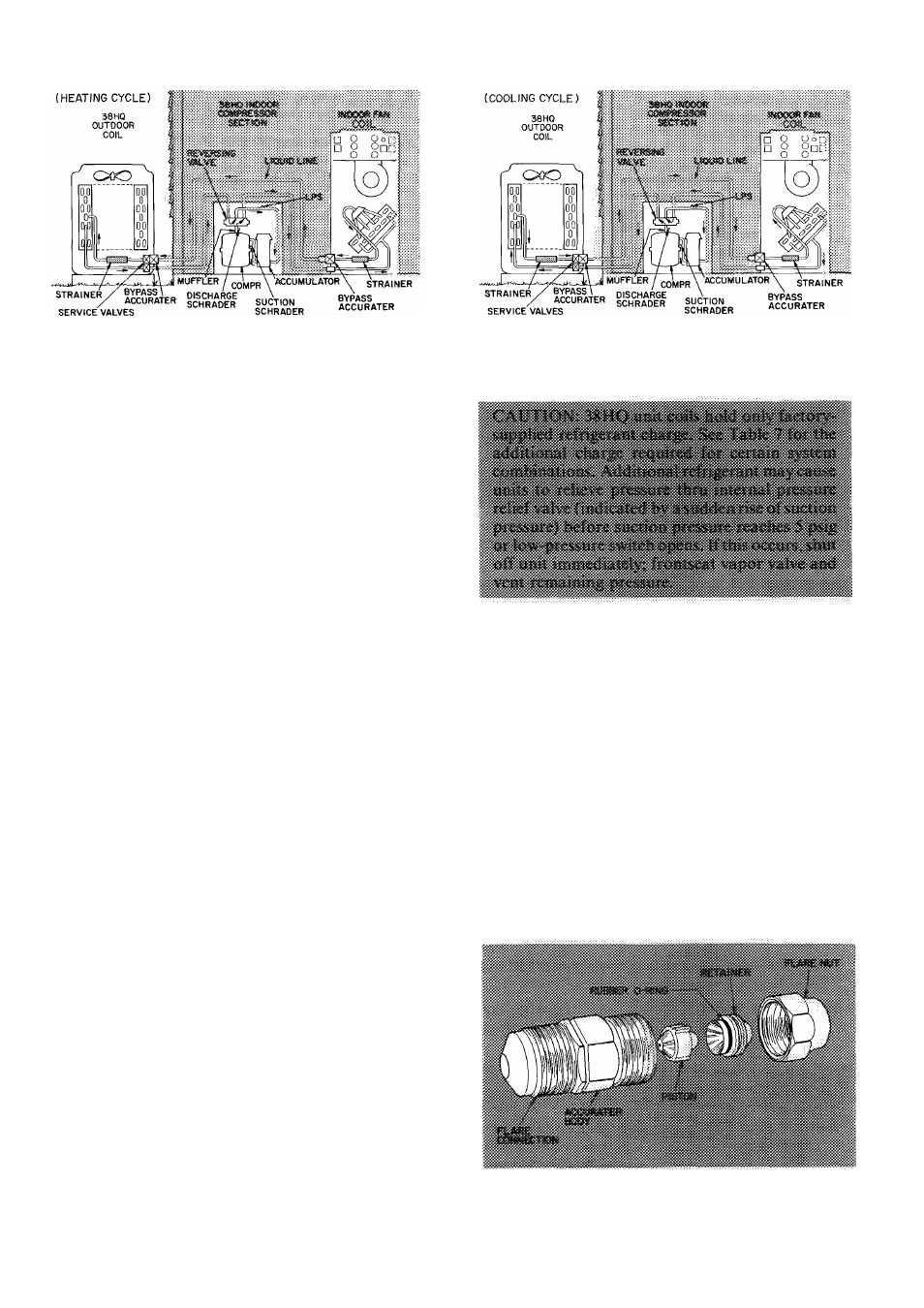

Fig. 25 — 38HQ Refrigerant Flow Diagrams

DEFROST

CONTROL,

consisting

of

a

defrost

timer, defrost thermostat and defrost relay, inter

rupts normal system heating operation every 90

minutes to defrost outdoor coil, if the coil saturated

suction

temperature

indicates

freezing

tempera

tures. Defrost control simultaneously stops outdoor

fan, energizes reversing valve solenoid to return

system to cooling cycle (outdoor eoil as condenser,

indoor

fan

coil

as

evaporator),

and

activates

accessory electric heater.

For the heat pump to defrost, 2 conditions are

necessary:

->1. Defrost timer switches LI from terminal 6 to

terminal 5.

2.

Refrigerant temperature from outdoor unit must

be cold enough to cause defrost thermostat con

tacts to close. Contacts close at 27 ( ± 4) F.

Every 90 minutes of elapsed running time the

defrost timer contacts close for 10 seconds. If the

defrost thermostat contacts are closed, the unit

defrosts. The defrost timer limits defrosting period

to 10 minutes. Normally the frost is removed and

the defrost thermostat eontacts will open to ter

minate defrosting before 10 minutes have elapsed.

Defrost thermostat contacts open at 80 F (± 6)

liquid refrigerant temperature. When defrosting is

terminated, the outdoor fan motor is energized and

reversing valve solenoid is de-energized returning

unit to heating cycle.

HEAT PUMP CIRCUITS shown in Fig. 25 are

refrigerant flow diagrams for heating and cooling

cycles.

Pumpdown Procedure (Cooling Cycle) — The

38HQ units may be pumped down in order to

make repairs on low side of system without losing

complete refrigerant charge.

1. Attach pressure gage to suetion service port.

2. Frontseat the liquid line valve on outdoor coil.

3. Start unit and run until suction pressure reaches

5 psig (see Caution) or low-pressure switch

opens.

4. Shut unit off and frontseat vapor line valve on

outdoor coil.

5. Vent remaining pressure.

AccuRater™ (Bypass Type) Servicing — See

Fig. 26 for bypass type AccuRater components. The

piston has a refrigerant metering hole thru it. The

retainer forms a stop for the piston in the refrig

erant bypass mode, and a sealing surface for liquid

line flare connection. To check, clean or replace

piston:

1. Shut off power to unit.

2.

Pump unit down using Pumpdown Procedure

described previously.

3.

Remove

liquid

line

flare

connection

from

AccuRater.

4.

Pull retainer out of body being careful not to

scratch flare sealing surface. If retainer does not

pull out easily, carefully use vise grips to

remove retainer.

Fig. 26 — AccuRater (Bypass Type)

Components

16