Carrier 38HQ User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE

’■Refrigerant Charging — The 38HQ940 outdoor

coil contains a factory charge of 7.1 lb of R-22; the

38HQ960 outdoor coil contains a factory charge of

10.0 lb. This charge is correct for all systems except

those listed in Table 7. When the amount of refrig

erant shown in Table 7 is added, the final charge will

agree with the amount stamped on the compressor

section nameplate.

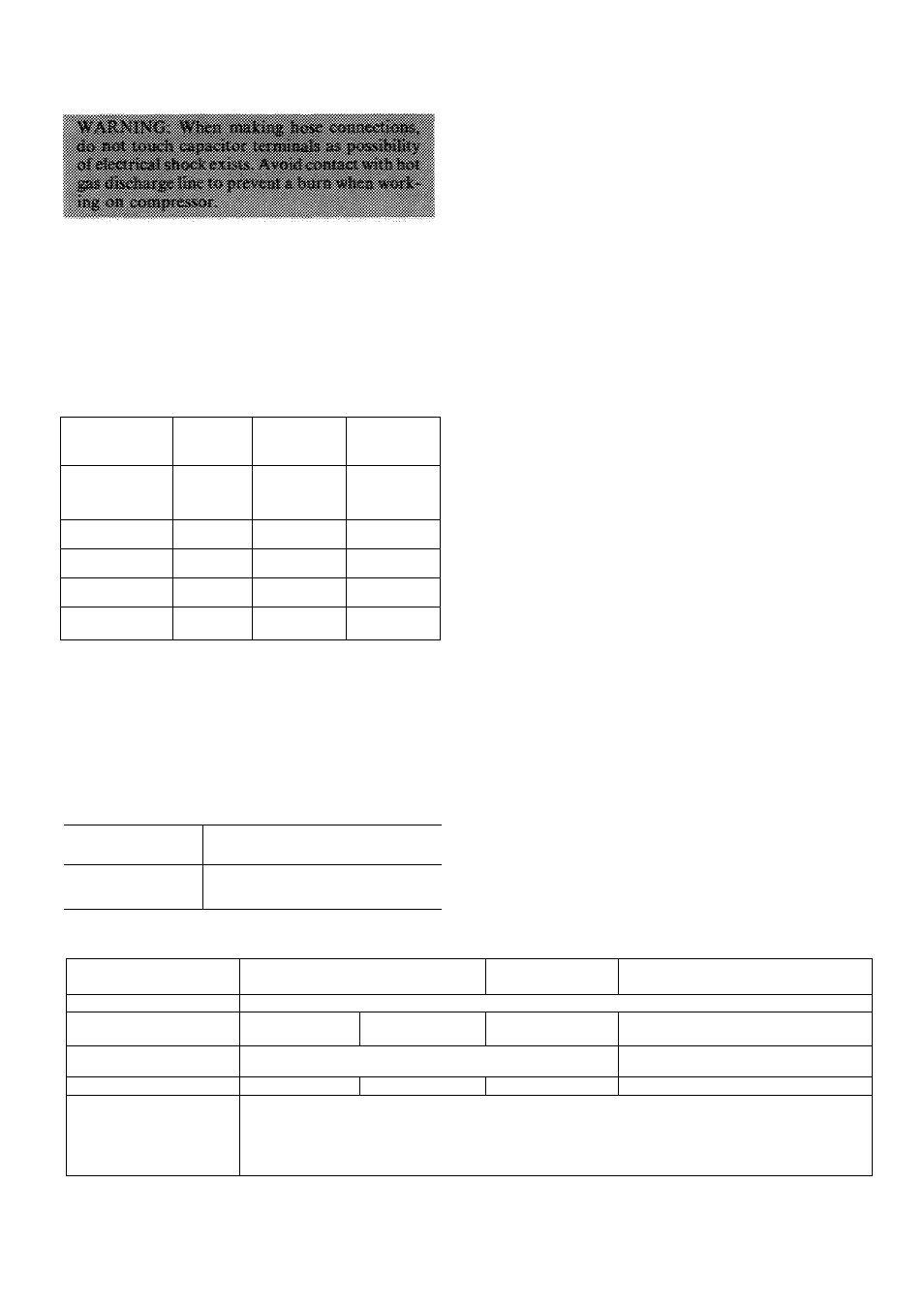

> Table 7 — Refrigerant Charging Data

INDOOR

COMPRESSOR

SECTION

OUTDOOR

COIL

INDOOR

FAN COIL

AMOUNT OF

R-22 TO BE

ADDED (oz)

38HQ120

38 H0940

40AQ030

28HQ.VQ030

40AQ036

28HQ,VQ036

I

7

7

15

15

38HQ127

38HQ940

40AQ036

28HQ,VQ036

8

8

38HQ134

38HQ940

28HQ,VQ036

40AQ036

14

14

38HQ140

38HQ960

28HQ,VQ042

40QB042

19

27

38HQ146

38HQ960

28HQ,VQ048

40QB048

19

27

The above charges are suited to systems with 25 ft

of recommended tubing. Adjust system charge for

refrigerant line lengths and diameters that differ

from 25 ft and 3/8-in. OD (liquid line), respectively,

using refrigerant weights shown in table below.

(Twenty-five feet of 3/8-in. OD tubing contains

14.4 oz of R-22.) Add R-22 charge to system if liquid

line is over 25 ft; remove charge if liquid line is

shorter than 25 feet.

LIQUID LINE

DIAM (in.)

OUNCES OF R-22/FT LENGTH

OF LIQUID LINE

3/8

58

5/16

36

1/4

21

When recharging is necessary during heating or

cooling season, weigh in total charge indicated in

Table 8. (Charge must be weighed in during heating

season.) Remove any refrigerant remaining in sys

tem before recharging. If system has lost complete

charge, evacuate system to 500 microns (29.7 in.

vacuum) before recharging. Service port connec

tions are provided on indoor compressor section

suction and discharge lines for evacuation and

charging. (See Fig. 24 for service port locations.)

Dial-a-charge

charging

cylinder

is

an

accurate

device used to recharge systems by weight. These

cylinders are available at refrigeration supply firms.

To check and/or adjust charge during cooling

season, use correct Cooling Cycle Charging Chart

(Fig. 10 thru 16) and follow Charging Chart Method

below. The charging chart may also be used as an

alternate method of recharging system.

To check system operation during heating cycle,

use correct Heating Cycle Operation Check Chart

(Fig. 17 thru 23). These charts indicate whether a

correct relationship exists between system operating

pressures and air temperatures entering indoor and

outdoor units. If pressure and temperature lines do

not intersect on chart, the system refrigerant charge

may not be correct or other system abnormalities

may exist. Do not use Operation Check Charts to

adjust refrigerant charge. Weigh charge into system.

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before

checking

charge,

and

after

each

charge

adjustment.

2. Measure suction pressure by attaching a gage to

indoor unit suction service port. (See Fig. 24 for

correct service port location.)

3.

Measure outdoor (coil inlet) air dry-bulb tem

perature with service thermometer.

4.

Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor fan coil.

5.

Refer to correct Charging Chart. Locate on

curves where outdoor air dry-bulb and indoor air

wet-bulb temperature lines intersect.

'-N

Table 8 — Service Data

INDOOR COMPR

SECTION 38HQ

120 j 127

134

140 146

REFRIG

R-22

COMPR MODEL*

Oil Rechg (oz)

MD2013HB

46

MD2713HB

46

MD3413HB

46

PC4616AD ! PC5316AD

76 1 76

OUTDOOR

COIL

38 H0940

38HQ960

R-22 CHG (lb)t

7 5

7.1t

7 1

100

FAN

Cfm

Rpm

Diameter (in.)

Motor Hp

Propeller — Direct Drive

3100 1 3600

1015 1080

20 20

1/5 1/4

*Refer to Service Parts catalog for replacement compressor model numbers

fFactory-supplied charge in outdoor unit for complete system Charge adjustment may be required on some systems See Table 7

783

10