Fig. 8 — control wiring connections, Step 6 — adjust evaporator-fan speed — adjust, Table 3 — heat anticipator settings – Carrier 50LJ008-014 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 3 — Heat Anticipator Settings

UNIT VOLTAGE

208/230

460

575

UNIT

Configuration

Configuration

Configuration

Heater kW

1 Stage

2 Stage

Heater kW

1 Stage

2 Stage

Heater kW

1 Stage

2 Stage

Stage 1

Stage 1

Stage 2

Stage 1

Stage 1

Stage 2

Stage 1

Stage 1

Stage 2

104, 160

03

NA

NA

139, 165

03

NA

NA

18 0, 36 0

0.3

NA

NA

50LJ

32 0, 24 8

06

0.3

03

27 8, 33 0

42 4, 50 0

0 9

06

03

41 7, 50 0

06

03

03

54.0

0.6

03

03

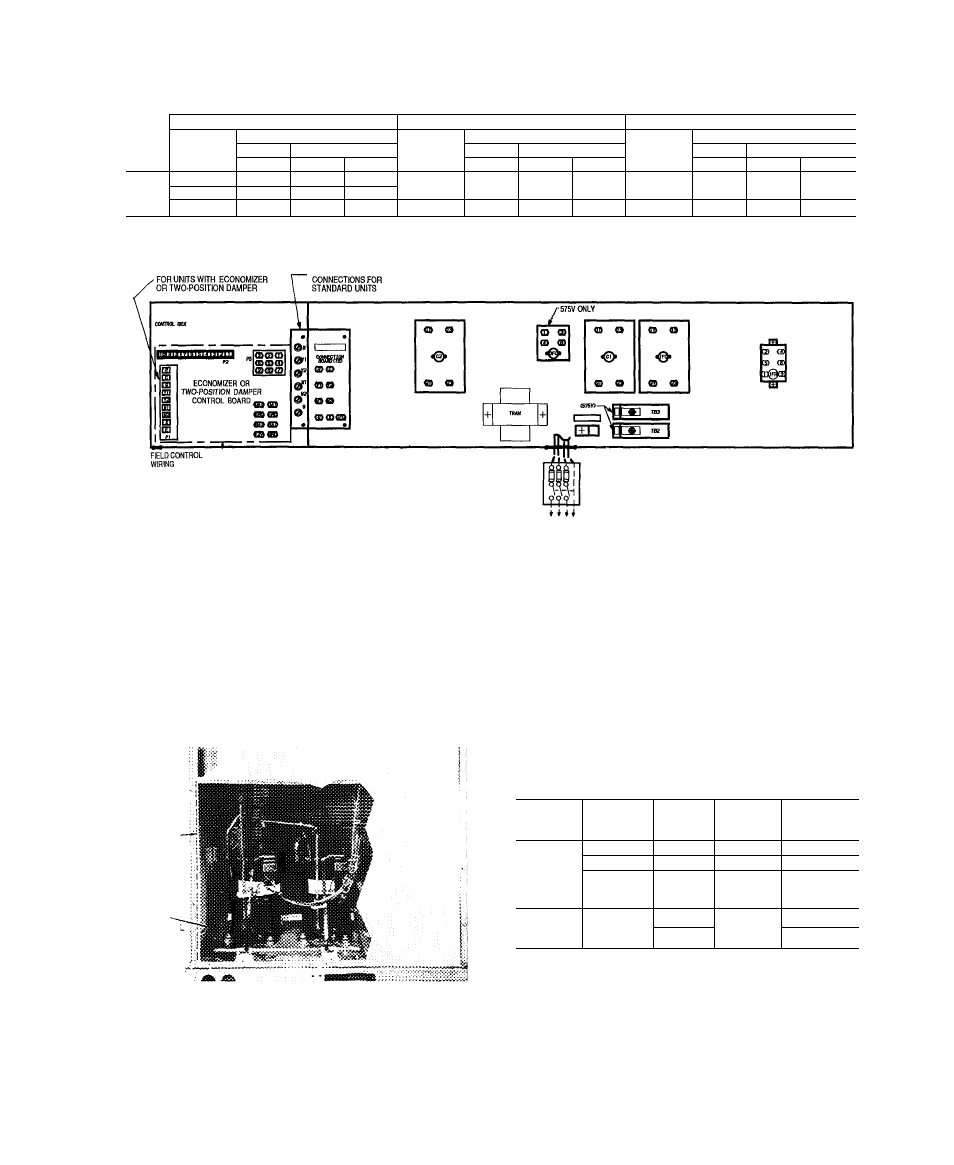

THERMOSTAT CONNECTIONS

THERMOSTAT

LEGEND

BAT

- Battery

C

— Contactor

DAT

— Discharge-Air Thermistor

EWIC/EMFC

— Energy Management Closed

EMO/EMFO

—

Energy Management Open

EQUIP

— Equipment

GND

— Ground

IFC

— Indoor-Fan Contactor

THREE-PHASE

POWER SUPPLY

IFR

— Indoor-Fan Relay

OFC

— Outdoor (Condenser) Fan Contactor

P

— Plug

TB

— Terminal Block

TRAN

— Transformer

---------- Field Wiring

Factory Wiring

Fig. 8 — Control Wiring Connections

RACEWAY-

HOLE IN

END PANE!

(HIDDEN)

Fig. 9 — Field Control Wiring Raceway

Step 6 — Adjust Evaporator-Fan Speed — Adjust

evaporator-fan speed to meet jobsite conditions.

For units with electric heating, required minimum cfm is

2250 for 50LJ008; 2550 for 50LJ009; and 3000 for 50LJ012

and 014 with the following exceptions.

UNIT

UNIT

VOLTAGE

HEATER

kW

UNIT

CONFIG-

ATION

REQUIRED

MINIMUM

CFM

208/230

42 4

Horizontal

3200

50LJ012

and 014

208/230

50.0

Horizontal

3200

460

50.0

Horizontal

or

Vertical

3200

50LJ008-

575

180

Horizontal

or

Vertical

2800

014

36 0

2350

Table 4 shows fan rpm motor pulley settings, Table 5

shows motor efficiencies and Table 6 gives accessory static

pressure drops. Refer to Tables 7-12 to determine fan speed

settings. Fan motor pulleys are factory set for speed shown

in Table 1.